A kind of preparation method of flavor oil solid decolorizer

A technology for flavor oil and decolorizing agent, applied in the field of preparation of solid decolorizing agent, can solve the problems of evaporation loss of trace fat-soluble nutrients, high operation energy consumption, oil loss and the like, and achieves easy implementation and popularization, simple and effective method, The effect of improving oil color index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of a flavor oil solid decolorizer, comprising the steps of:

[0016] 1) Activated clay alkalization: prepare 0.2mol / L NaOH aqueous solution (i.e. strong alkali dilute solution); take 100 parts by weight of activated clay, stir and disperse in 300 parts by weight of water, heat to 60°C, add 0.2mol The NaOH aqueous solution of / L carries out alkalization, controls the alkalization terminal point to pH7.0 with the pH meter, stops dripping NaOH aqueous solution, continues to stir for 30 minutes;

[0017] 2), solid-liquid separation / drying: Use a centrifuge to separate the solids, spread them out and put them in an oven at 110°C for 2 hours [control the moisture content after drying to no more than 8.0% (mass)] to obtain the decolorized solid flavor oil agent (or alkalized activated clay decolorizer).

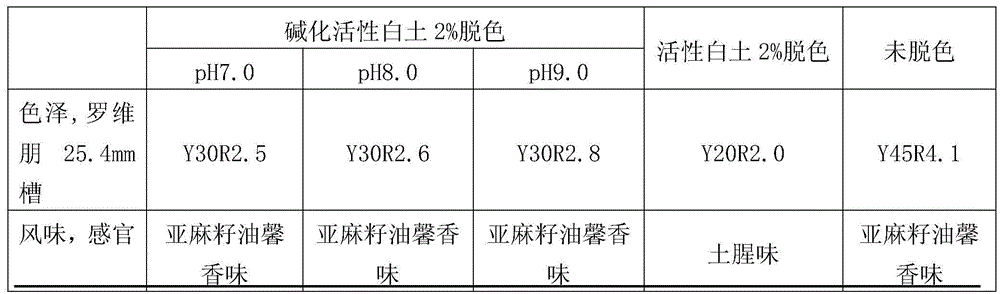

[0018] Decolorization effect test: Take 500 parts of pressed fragrant sunflower oil, use Lovibond colorimeter to detect its color index as Y31.1R4.0 (25...

Embodiment 2

[0020] The same method as in Example 1 was used for the preparation of the decolorizing agent and the inspection of the decolorizing effect, except that the alkalization endpoint was controlled to be pH 8.0 during the preparation of the decolorizing agent. Pressed Luzhou-flavored sunflower oil is decolorized. According to sensory evaluation, its flavor is no different from that of Luzhou-flavored pressed sunflower oil. The color index is Y15R2.3 (133mm groove), and the coolness and color of the oil have been significantly improved.

Embodiment 3

[0022] The same method as in Example 1 was used for the preparation of the decolorizing agent and the inspection of the decolorizing effect, except that the alkalization endpoint was controlled to be pH9.0 during the preparation of the decolorizing agent. Pressed Luzhou-flavored sunflower oil is decolorized. According to sensory evaluation, its flavor is no different from that of Luzhou-flavored pressed sunflower oil. The color index is Y15R2.4 (133mm groove), and the coolness and color of the oil have been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com