Solidly mounted film bulk acoustic resonator and method for preparing fully insulated Bragg reflecting grating thereof

A thin-film bulk acoustic wave and Bragg reflection technology, applied in electrical components, impedance networks, etc., can solve the problems of electro-acoustic performance degradation and instability of devices, and achieve the effects of eliminating parasitic capacitance, excellent sound wave reflection effect, and good sound wave reflection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

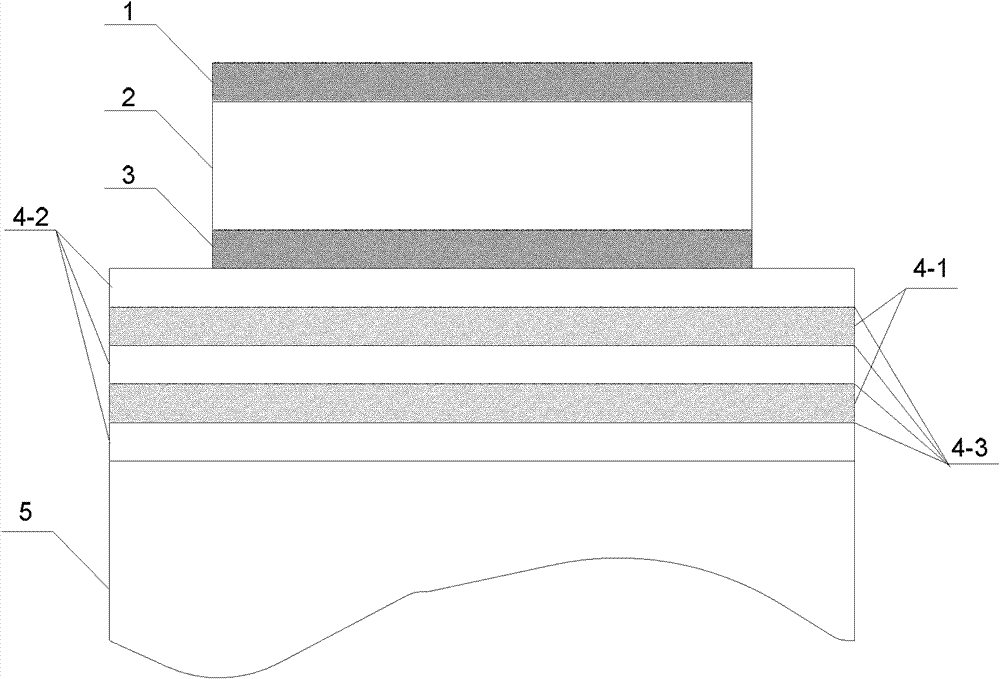

[0019] Specific implementation mode 1. Combination figure 1 Description of this embodiment, the fixed film bulk acoustic resonator, which includes an upper electrode 1, a lower electrode 2, a piezoelectric film 3, a fully insulated Bragg reflection grating 4 and a Si substrate 5, an upper electrode 1, a lower electrode 2 and a piezoelectric The thin film 3 forms a piezoelectric oscillating stack sandwich structure centered on the piezoelectric thin film 3 , the piezoelectric oscillating stack grows directly on the fully insulated Bragg reflective grating 4 , and the fully insulated Bragg reflective grating 4 grows on the Si substrate 5 .

specific Embodiment approach 2

[0020] Embodiment 2. The difference between this embodiment and the solid-mount thin-film bulk acoustic resonator described in Embodiment 1 is that the fully insulated Bragg reflection grating 4 is a low acoustic impedance film layer 4-2, and the Low acoustic impedance film layer 4-2 is SiO 2 film.

[0021] The fully insulated Bragg reflection grating 4 described in this embodiment has a single low acoustic impedance film layer 4-2, and has a simple structure. This low acoustic impedance film layer 4-2 can utilize the radio frequency magnetron sputtering system to deposit SiO 2 film.

specific Embodiment approach 3

[0022] Embodiment 3. This embodiment is a further limitation of the fixed-film bulk acoustic resonator described in Embodiment 2. The film thickness of the low acoustic impedance film layer 4 - 2 is 300-2000 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com