Infrared bridge type temperature measurement sensor

A temperature measurement sensor and bridge-type technology, applied in the sensor field, can solve the problems of low Seebeck coefficient, limited temperature resolution of infrared temperature measurement sensor, larger output resistance of thermopile, etc., so as to improve work adaptability and sensitivity. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

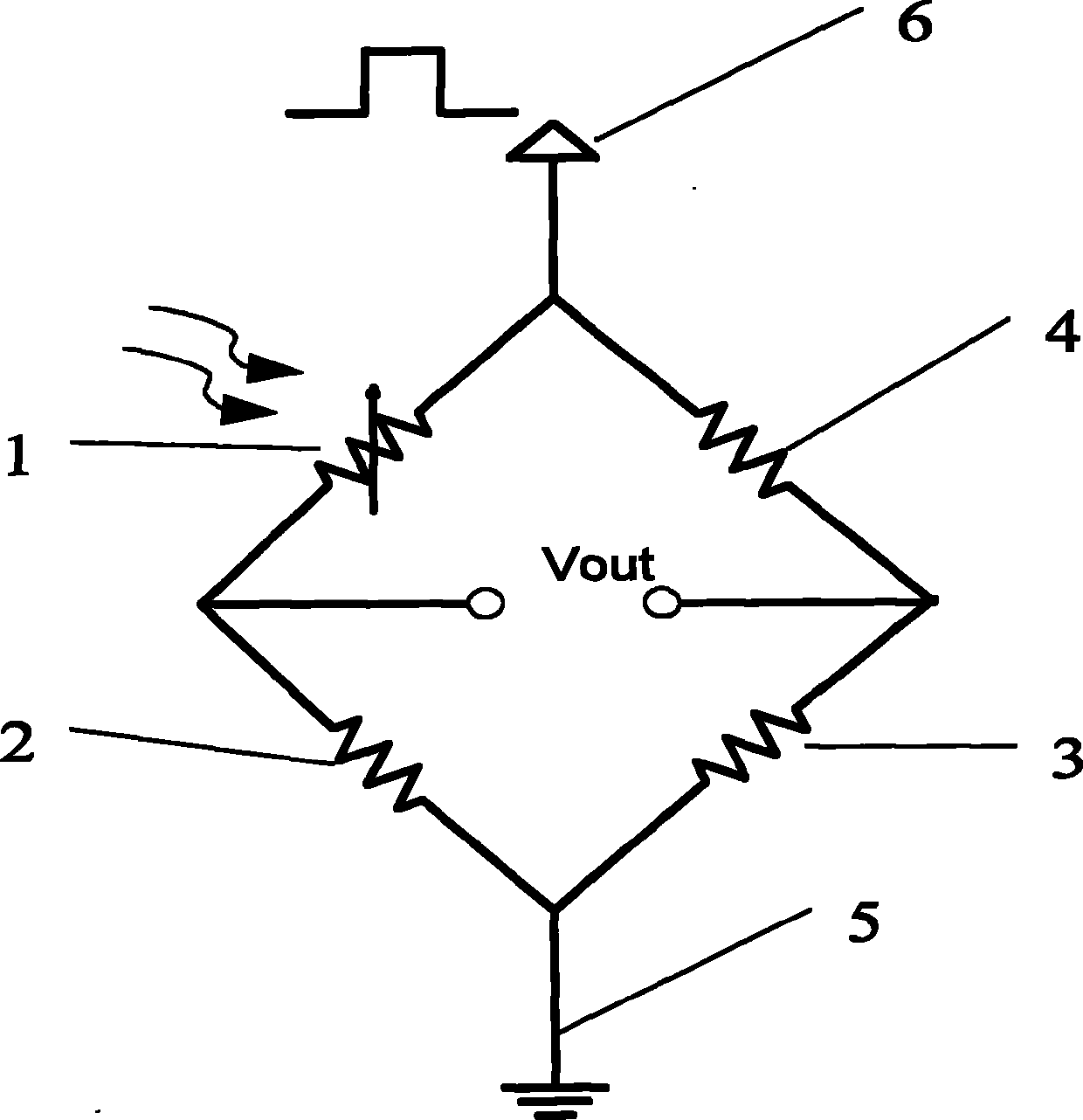

[0024] Such as figure 1 As shown, the sensor embodiment of the present invention includes photoresistor 1, environment reference resistor 2, environment reference resistor 3, Joule heat reference resistor 4, power ground 5 and power supply 6, the photoresistor 1, environment The reference resistor 2, the environment reference resistor 3, and the Joule heat reference resistor 4 are all fabricated on the substrate, and the substrate can be made of silicon or glass, and other materials that can be used as sensor substrates. The present embodiment 1 takes the silicon substrate as an example . In order to reduce the resistance temperature rise caused by Joule heat, the sensor adopts the pulse power supply mode, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com