Supercharger with controllable hydraulic pressure and flow output

A flow output, liquid pressure technology, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of large hydraulic shock, low work efficiency, large floor space, etc., to achieve improved work efficiency and safety performance, less floor space Small, simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

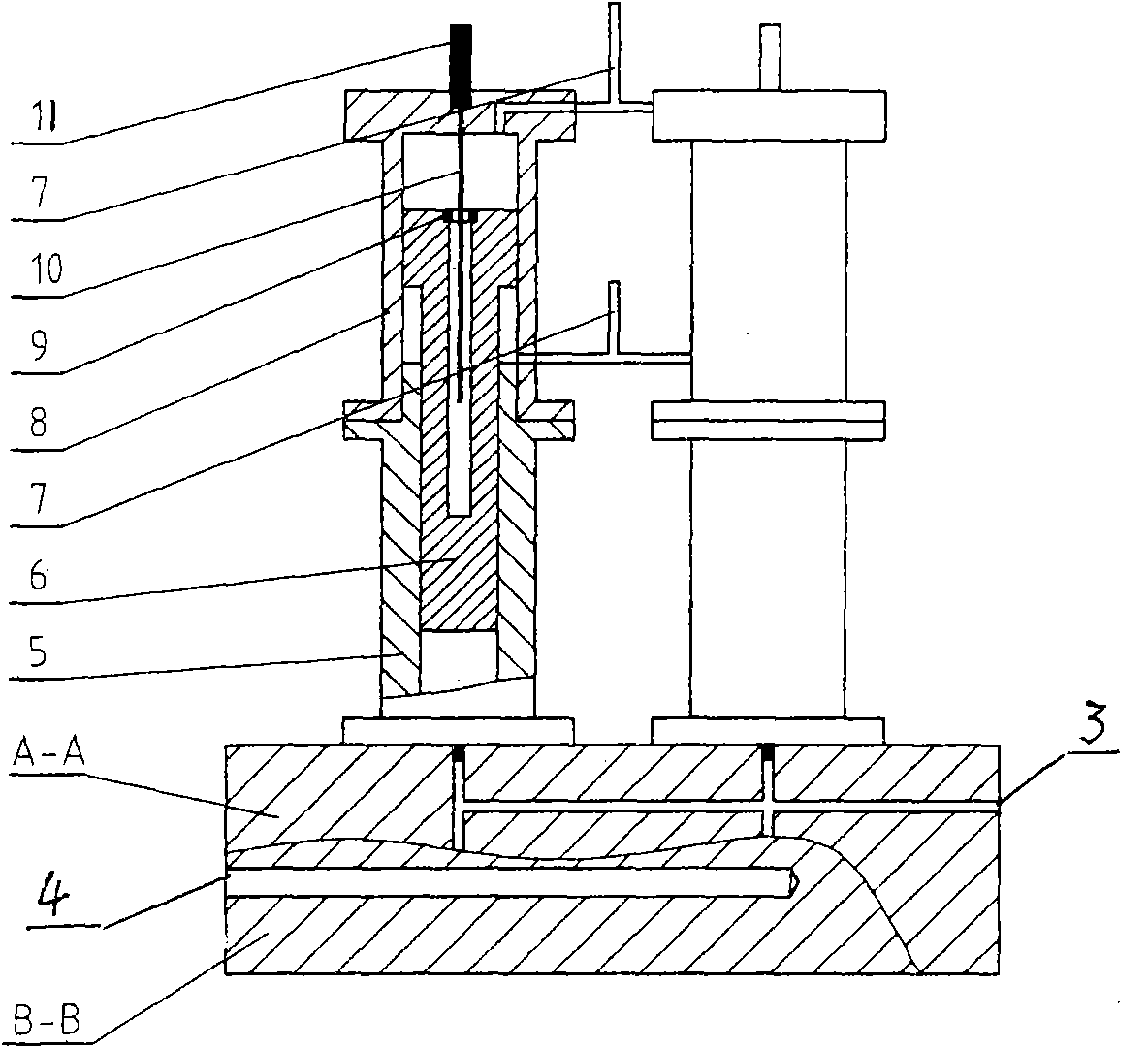

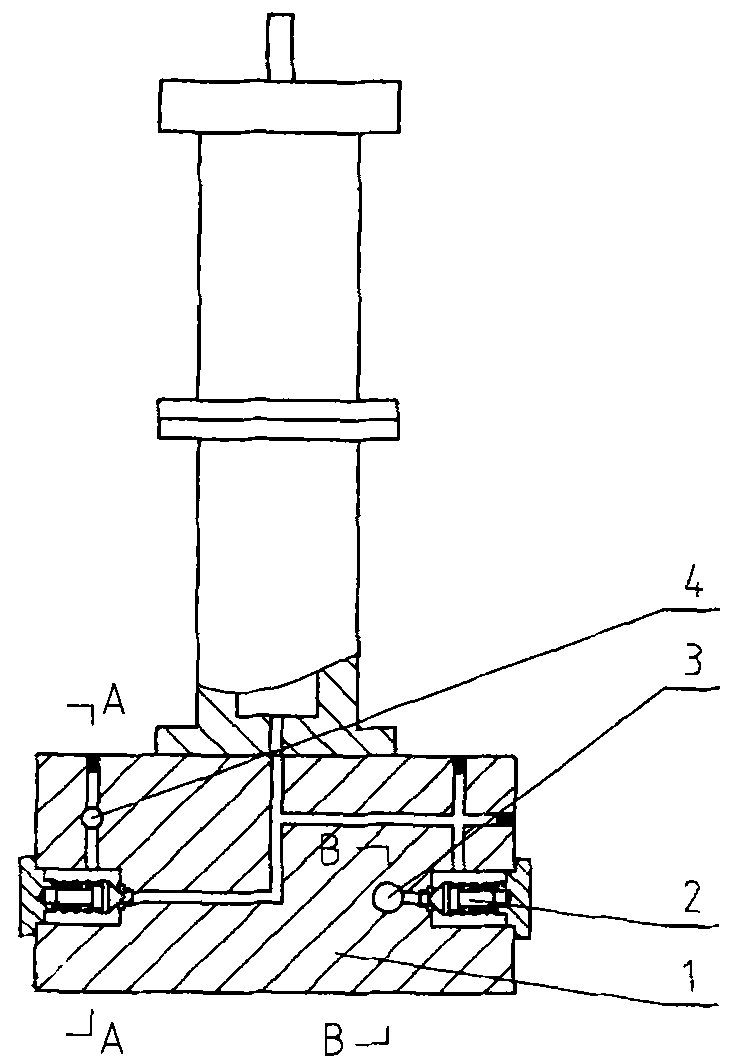

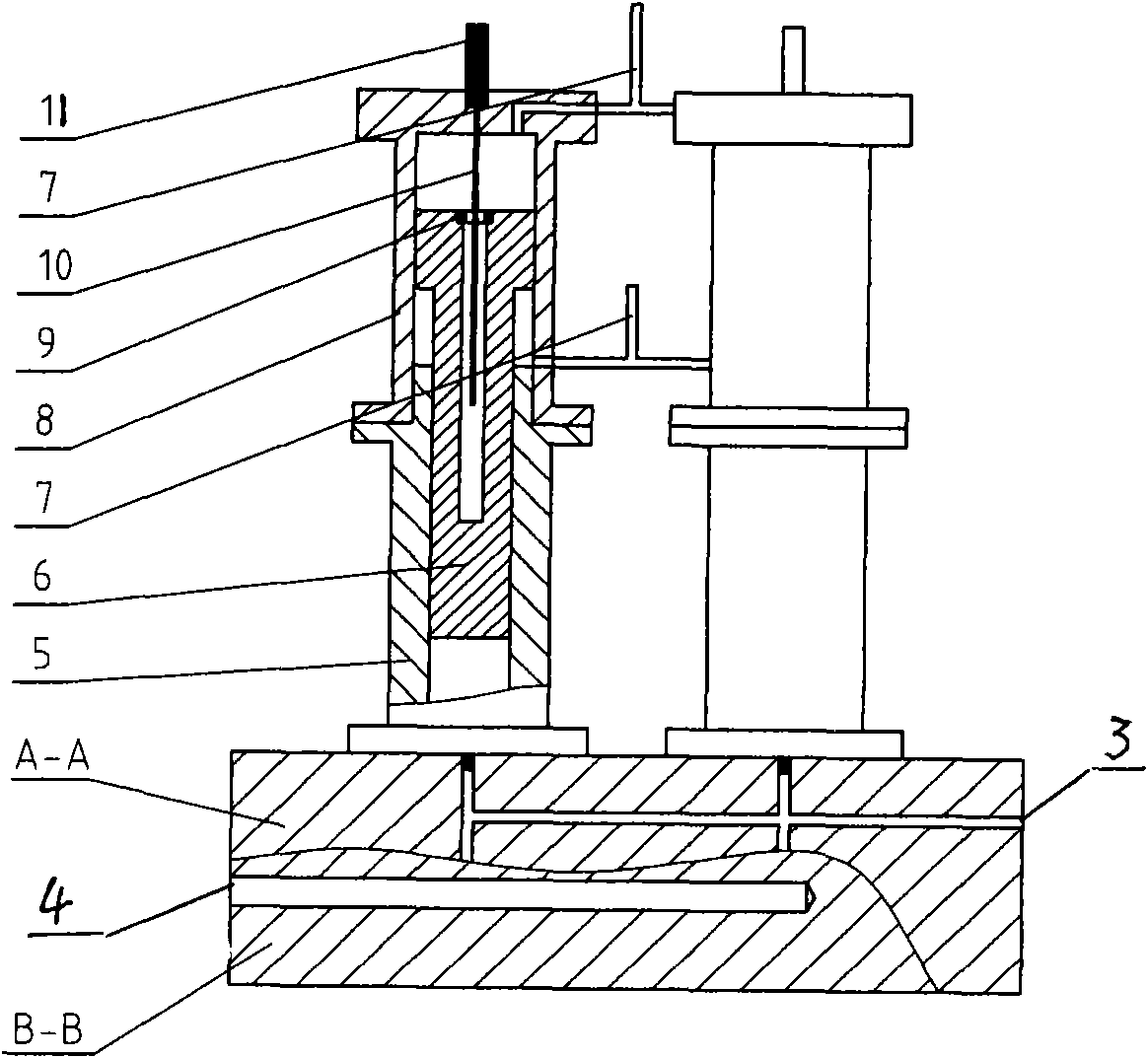

[0022] A pressure booster with controllable output of liquid pressure and flow is composed of two booster cylinders and a valve seat (1) connecting the two booster cylinders. Wherein, each booster cylinder is composed of the upper hydraulic cylinder (8), the lower plunger cylinder (5), the piston rod (6) and the displacement sensor, and the magnetic ring (9) of the displacement sensor is installed on the piston rod ( 6) The center hole port, the sensing rod (10) is inserted into the center hole of the piston rod (6) through the magnetic ring (9), and the sensor electronic head (11) at the top end of the sensing rod (10) is fixed on the hydraulic cylinder (8) top.

[0023] Two upright booster cylinders are installed on the valve seat (1), and there are water inlet hole (4), water outlet hole (3), check valve (2) in the valve seat (1), water inlet hole (4) and The external water tank is connected, and the water outlet (3) is connected with the hydraulic test tube machine. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com