Screw cascade waste heat energy generating device and generating method

A power generation device and cascade technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of insufficient low-temperature heat recovery, limited thermal energy utilization rate, and low energy conversion efficiency, so as to improve energy conversion efficiency and realize The effect of power generation efficiency and resource utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

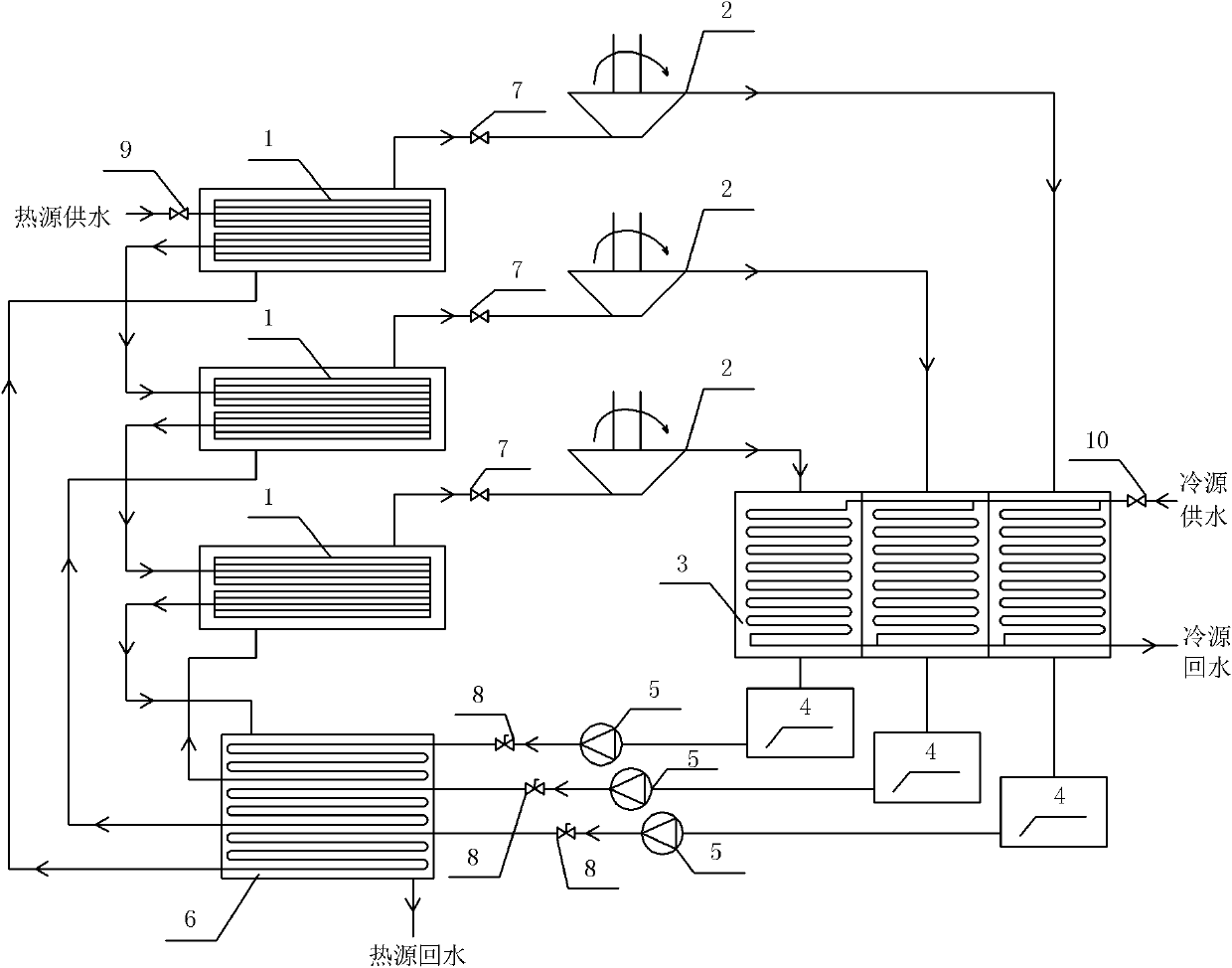

[0028] Using a three-stage generating set, the three-stage generating set runs the following steps:

[0029](1) Let the cold water circulate in parallel through the condensers of the three-stage generator sets and make the hot water pass through the tube side of the flooded evaporator 1 and the tube side of a shell-and-tube preheater 6 of the generator sets of all levels arranged in series in sequence Shell side, the tube side of the shell-and-tube preheaters of the generator sets at all levels are independently arranged in a shell; (2) Start the three-stage generator sets one by one, and each generator set runs the following steps: the working of each generator set The supercooled liquid of the organic working medium at the outlet of the mass circulation pump 5 enters the tube side of the shell-and-tube preheater 6, and after the heat absorption reaches saturation, it enters the shell side of the flooded evaporator 1 of each generating set to form boiling heat exchange and eva...

Embodiment 2

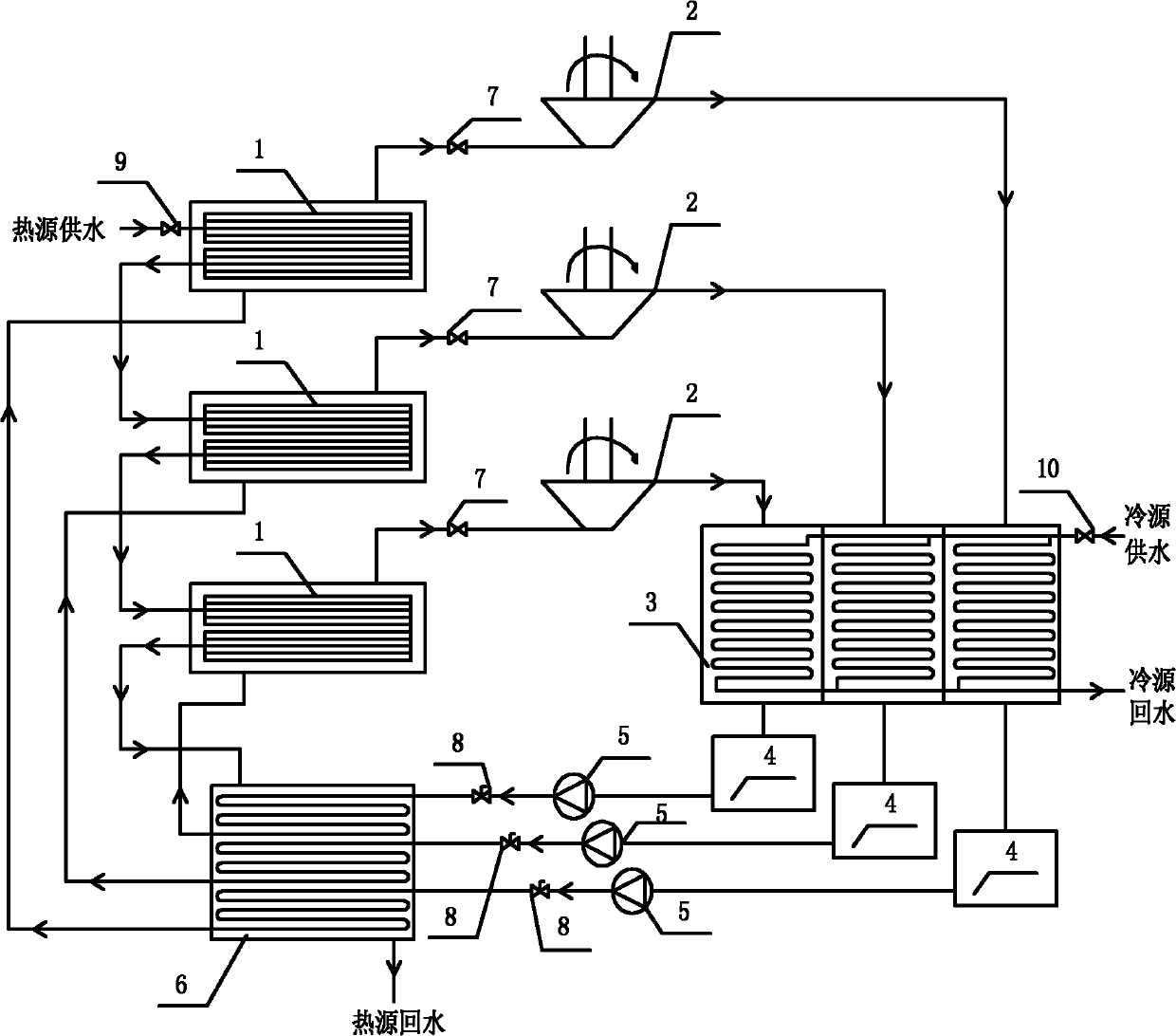

[0032] Using a secondary generating set, the secondary generating set operates the following steps:

[0033] (1) Let the cold water circulate through the condensers of the two-stage generator sets in parallel and make the hot water pass through the tube side of the flooded evaporator 1 and the tube side of a shell-and-tube preheater 6 of the generator sets at all levels arranged in series in sequence Shell side, the tube side of the shell-and-tube preheater of the generator sets at all levels are independently arranged in a shell; (2) Start the second-level generator sets one by one, and each generator set runs the following steps: the working of each generator set The supercooled liquid of the organic working medium at the outlet of the mass circulation pump 5 enters the tube side of the shell-and-tube preheater 6, and after the heat absorption reaches saturation, it enters the shell side of the flooded evaporator 1 of each generating set to form boiling heat exchange and evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com