Cleaning agent of oil refining device and preparation method thereof

A technology for oil refining equipment and cleaning agents, which is applied in the direction of non-ionic surface active compounds, etc., can solve the problems of poor thermal stability of cleaning agents, complicated preparation methods, and inapplicability to cleaning of oil refining equipment, etc., and achieves strong solubility, good thermal The effect of stability and good cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

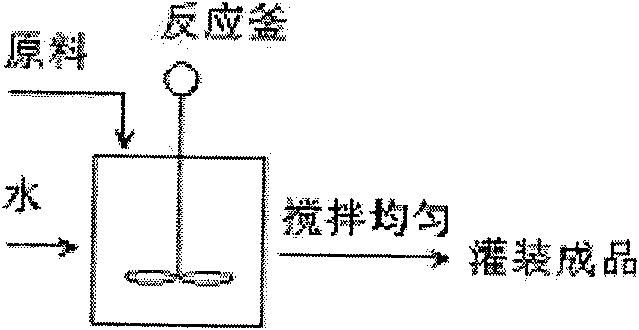

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one, the cleaning agent of the oil refinery of the present embodiment, the basic composition of its formula is: 38 parts of D-limonene; 9 parts of polyether; parts; 0.5 parts of ethylene glycol monobutyl ether; 15 parts of water. D-Limonene is a terpene hydrocarbon with the molecular formula C 10 h 16 , with a melting point of -74.3°C and a boiling point of 178°C. Water is deionized water. The polyether is polyoxypropylene polyoxyethylene block polymer. Prepare the raw materials according to the above formula, then heat and melt 4 parts of oleic acid monoethanolamine, add 4 parts of dodecylbenzenesulfonic acid and 0.5 parts of ethylene glycol monobutyl ether, stir well, add 15 parts of water to dissolve 9 parts of polyether solution, and finally add 38 parts of D-limonene, and continue to stir until clear and transparent, and then post-fill the finished product.

Embodiment 2

[0019] Embodiment two, the cleaning agent of the oil refinery of the present embodiment, the basic composition of its formula is: 45 parts of D-limonene; 11 parts of polyether; 6 parts of monoethanolamine of oleic acid fatty acid; 8 parts of dodecylbenzenesulfonic acid 2 parts; 2 parts of ethylene glycol monobutyl ether; 30 parts of water. D-Limonene is a terpene hydrocarbon with the molecular formula C 10 h 16 , with a melting point of -74.3°C and a boiling point of 178°C. Water is deionized water. The polyether is polyoxypropylene polyoxyethylene block polymer. Prepare the raw materials according to the above formula, then heat and melt 6 parts of oleic acid monoethanolamine, add 8 parts of dodecylbenzenesulfonic acid and 2 parts of ethylene glycol monobutyl ether, stir well, add and dissolve with 30 parts of water 11 parts of polyether solution, and finally add 30 parts of D-limonene, and continue to stir until clear and transparent, and then post-fill the finished prod...

Embodiment 3

[0020] Embodiment three, the cleaning agent of the oil refinery of the present embodiment, the basic composition of its formula is: 57 parts of D-limonene; 13 parts of polyether; 3.5 parts of ethylene glycol monobutyl ether; 40 parts of water. The formula also contains: 0.05 parts of 2,6-tert-butyl-p-cresol as an antioxidant. D-Limonene is a terpene hydrocarbon with the molecular formula C 10 h 16 , with a melting point of -74.3°C and a boiling point of 178°C. Water is deionized water. The polyether is polyoxypropylene polyoxyethylene block polymer. Prepare the raw materials according to the above formula, heat and melt 8 parts of linseed oil fatty acid monoethanolamine, add 12 parts of dodecylbenzenesulfonic acid and 3.5 parts of ethylene glycol monobutyl ether, and 0.05 parts of 2,6-tert-butyl p- Cresol, after stirring evenly, add 13 parts of polyether solution dissolved in 40 parts of water, and finally add 57 parts of D-limonene, and continue to stir until clear and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com