Glyphosate synthesis process

A synthesis process, a technology of glyphosate, which is applied in the fields of compounds of Group 5/15 elements of the periodic table, chemical instruments and methods, and organic chemistry, etc. problems, to achieve the effect of reducing side reactions, saving production costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

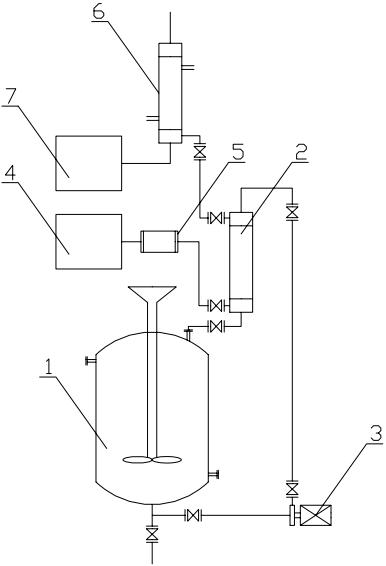

Image

Examples

Embodiment 1

[0033] Take 650 grams of methanol; 198 grams of triethylamine; put it into a 3000 ml four-neck bottle, add 115 grams of paraformaldehyde under stirring, heat, control the temperature at 45 ° C, and the reaction time is 45 minutes. The reaction solution is clear and transparent; cold water bath Cool down to 38°C, add 145 grams of glycine (98.5%); the temperature rises, remove the cold water bath when it reaches 42°C, control the temperature at 42°C, and react for 21 minutes. The reaction solution is clear and transparent again. At this time, the reaction solution is transferred to Straight tube condenser equipped with potassium-type 3A molecular sieve, the lower outlet of the condenser is connected to another reaction bottle through a rubber tube, the rubber tube uses a screw clamp to control the flow rate, about 30 drops per minute, and the dripping is completed in 75 minutes. The detected moisture is 0.09% .

[0034] Add 216 grams of dimethyl phosphite through a separatory fu...

Embodiment 2

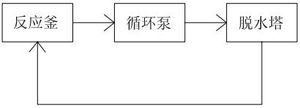

[0037] Add 6500kg of methanol to the reaction kettle; 1980kg of triethylamine, add 115g of paraformaldehyde under stirring, heat, the temperature rises to 50°C, the reaction time is 55 minutes, the reaction liquid is clear and transparent; open the coil to cool down to 40°C, add glycine (98.5%) 1450kg; the temperature rises, adjust the amount of cold water to control the temperature at 44°C, and the reaction time is 15 minutes. The reaction liquid is clear and transparent again. Open the circulation dehydration system connected with the circulation pump and the sodium-type 4A molecular sieve dehydration tower to maintain the circulation reaction for 50 Minutes, the detected moisture is 0.1%.

[0038] Add 2159.5 kg of dimethyl ester; turn on the coil for 5°C water cooling, control the temperature not to exceed 54°C, and react at 54°C for 100 minutes. The reaction liquid is clarified, the circulation pump is stopped, and the feed liquid is transferred to the hydrolysis kettle fo...

Embodiment 3

[0042] A. Depolymerization reaction: Depolymerize methanol, triethylamine and paraformaldehyde at 45°C for 45 minutes to obtain a depolymerization liquid; the molar ratio of methanol, triethylamine and paraformaldehyde is 5.0:0.5:1 ;

[0043] B. Addition reaction: After cooling down to 38°C, add glycine with a mass fraction of 98.5% to the depolymerization solution for addition reaction, and react at 42°C for 15 minutes until the addition reaction liquid is clear and the solid disappears; The addition is that the mol ratio with triethylamine in step A is 1:1;

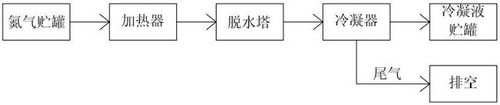

[0044] C. Cyclic dehydration treatment and regeneration of dehydrating agent: While continuing the addition reaction of the clarified addition reaction liquid, use 3A molecular sieve to circulate dehydration treatment to obtain dehydration addition liquid; 3A molecular sieve is regenerated with nitrogen at 100°C, The treated nitrogen is condensed to recover methanol and triethylamine, and the tail gas is emptied;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com