Method and equipment for preparing dumplings

A method for making dumplings and a technology for dumplings, which are applied in food preparation, dough forming and cutting equipment, baking, etc., can solve the problems of insufficiently beautiful appearance, insufficiently delicious taste, and poor taste of the dough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The dumpling making method and making equipment of the present invention will be described below with reference to the accompanying drawings.

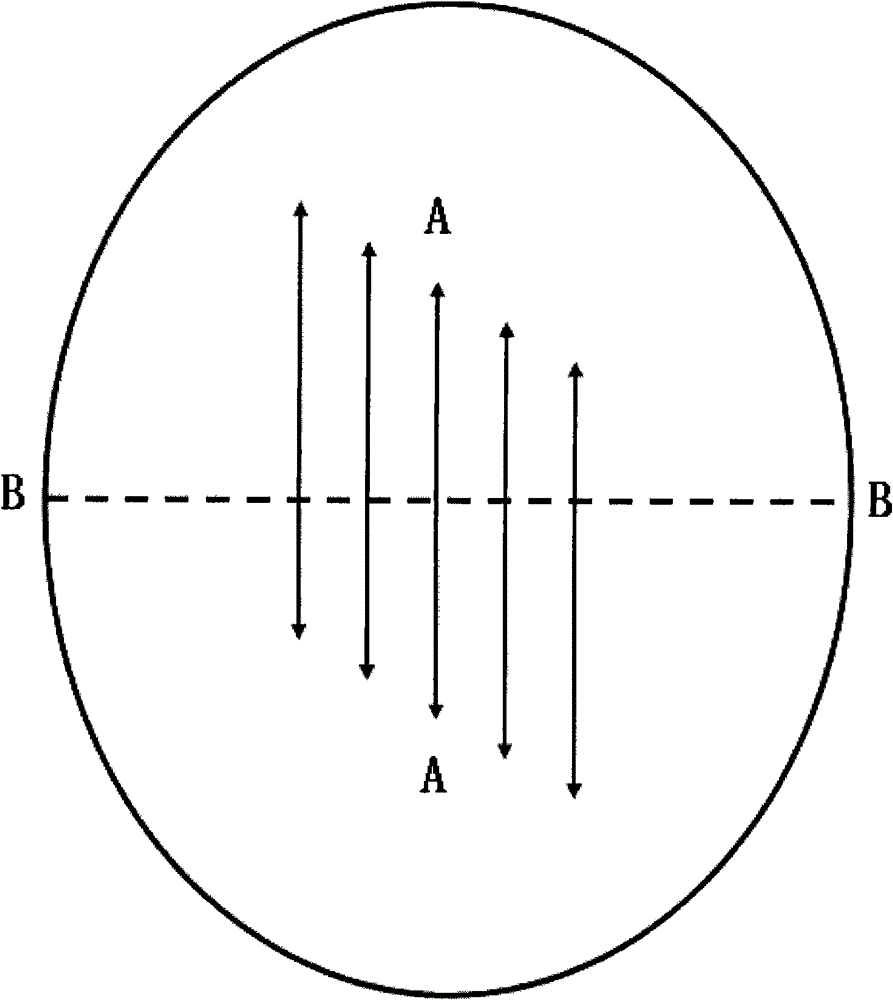

[0018] figure 1 A schematic diagram showing the folding line of the dumpling wrapper in the dumpling making method of the prior art. The steps of the dumpling making method in the prior art are: cutting the dough skin with the texture formed by unidirectional stretching pressed by the machine into dumpling wrappers of specified shape; filling the dumpling stuffing on the dumpling wrapper; taking the texture of the dumpling wrapper The direction becomes the folding line of basic 90 degree included angle to fold dumpling wrapper and form dumpling.

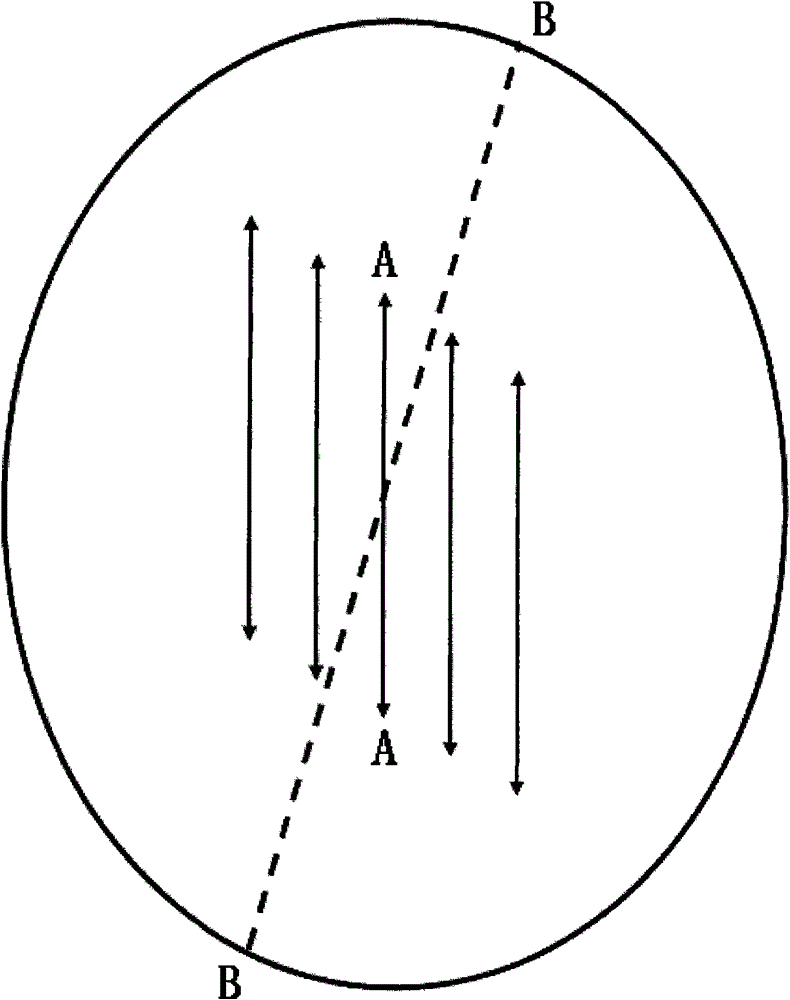

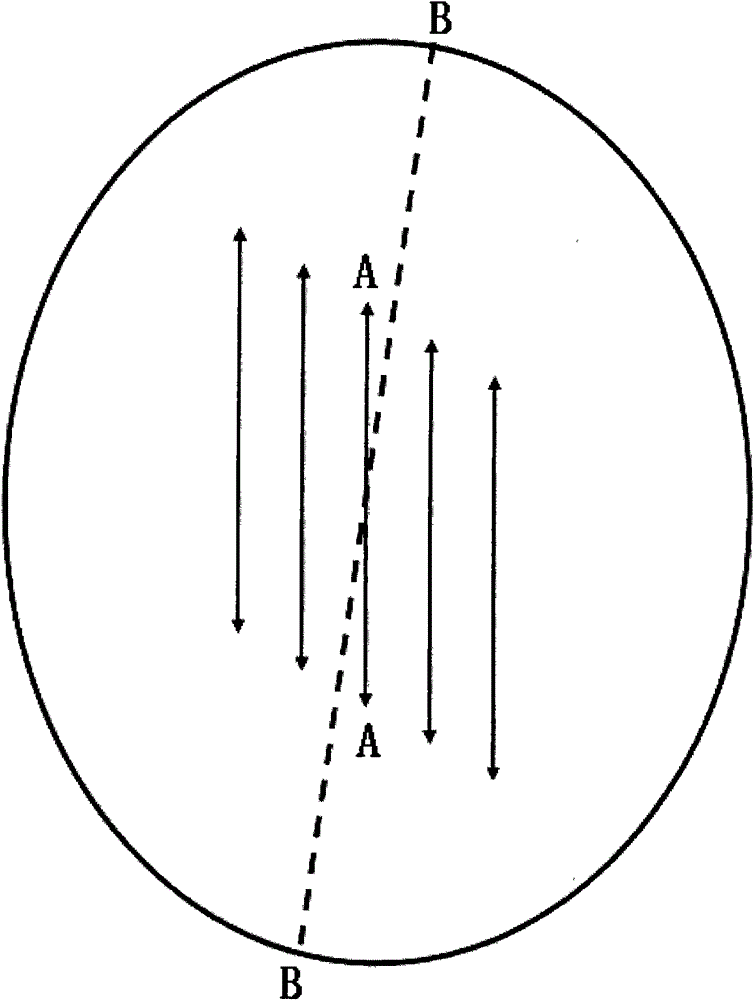

[0019] The dumpling production method of the present invention differs from the production method of the prior art in that in the production process of the dumpling, the grain direction of the dumpling wrapper is in the range of 0 to 20 degrees (including 0 degrees and 20 degrees). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com