Multistage transmission

一种变速器、速度的技术,应用在齿轮传动装置、带有齿的元件、皮带/链条/齿轮等方向,能够解决不能被最终释放、换挡位置和实际速度不匹配、无法进行换挡等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

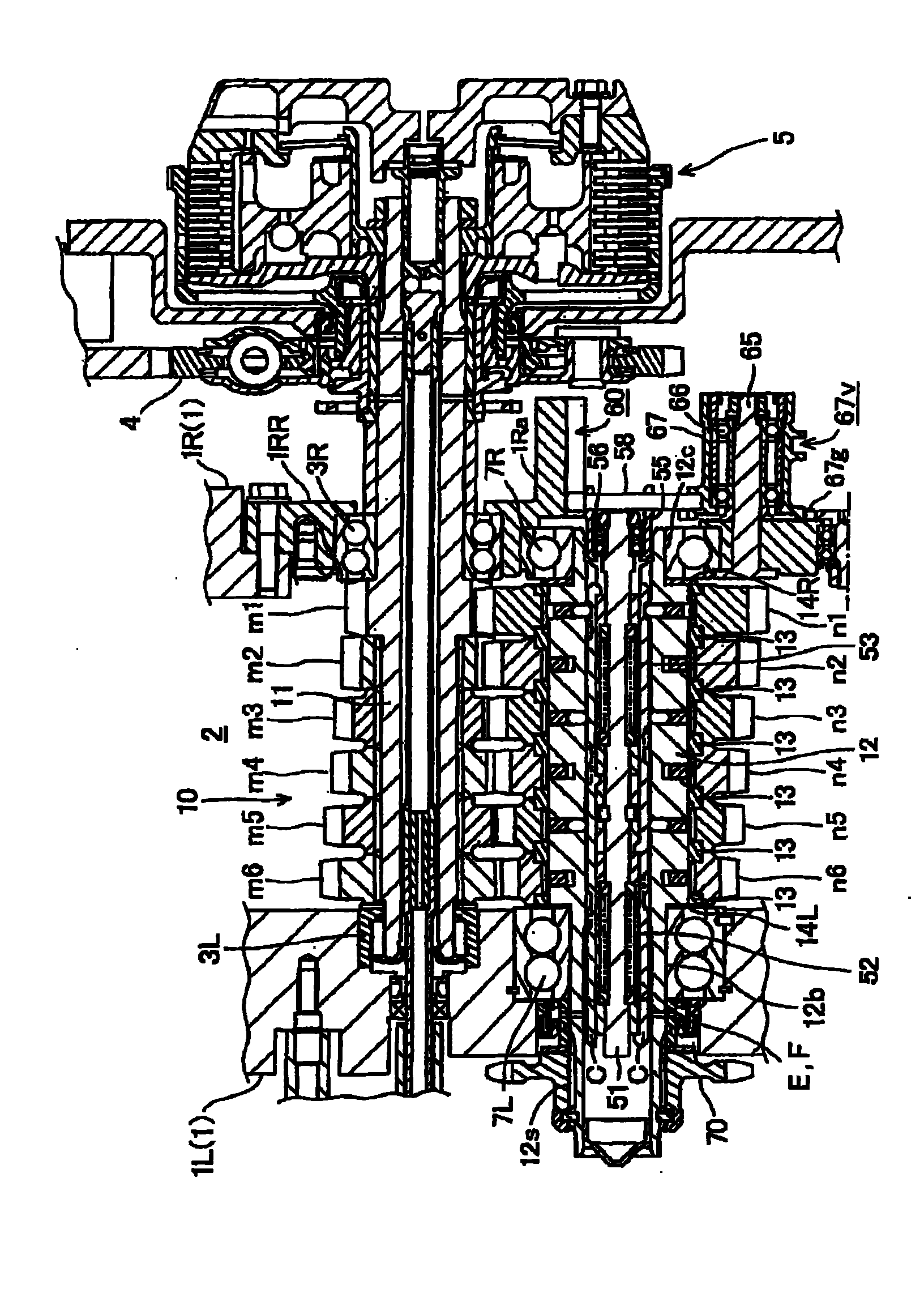

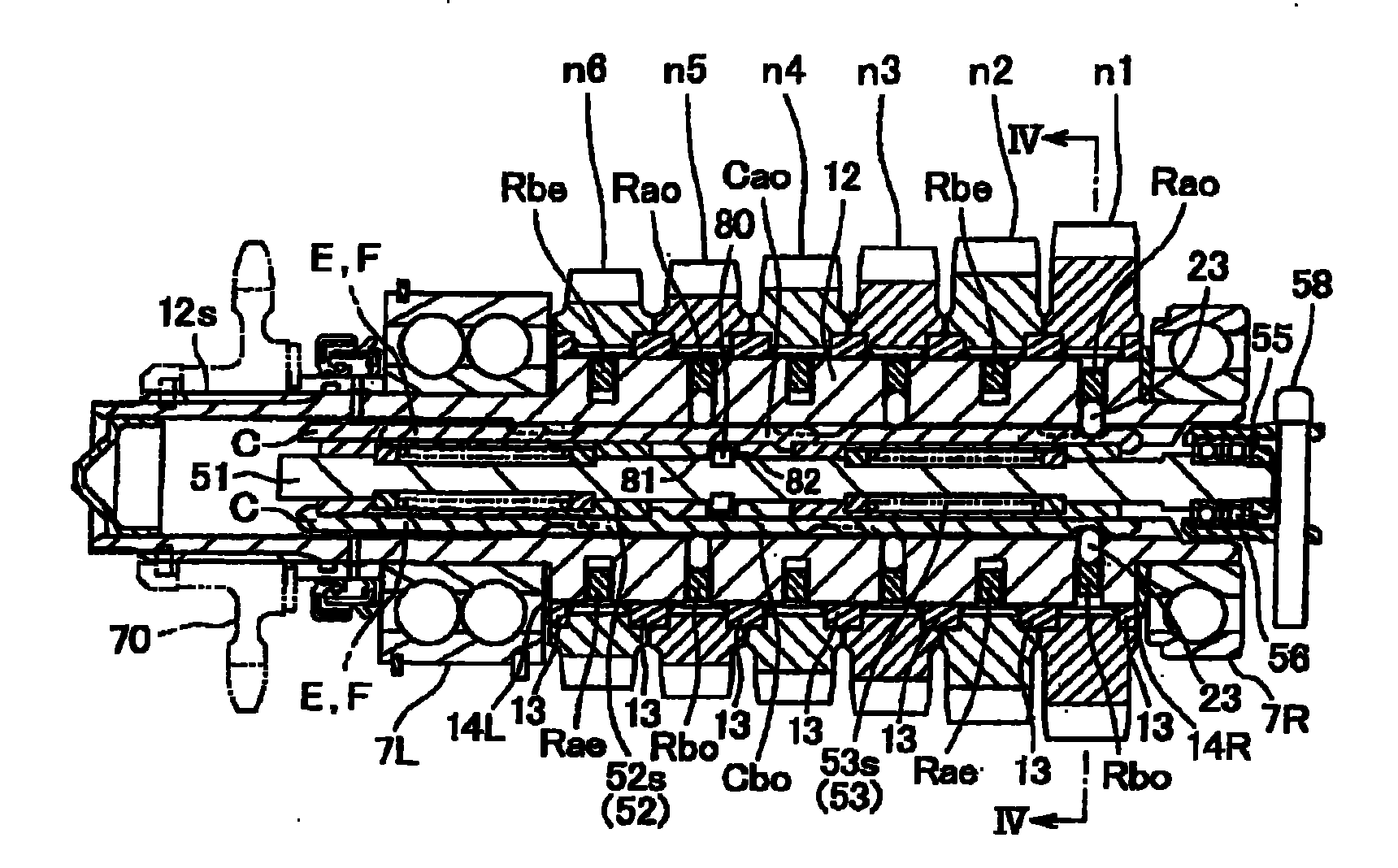

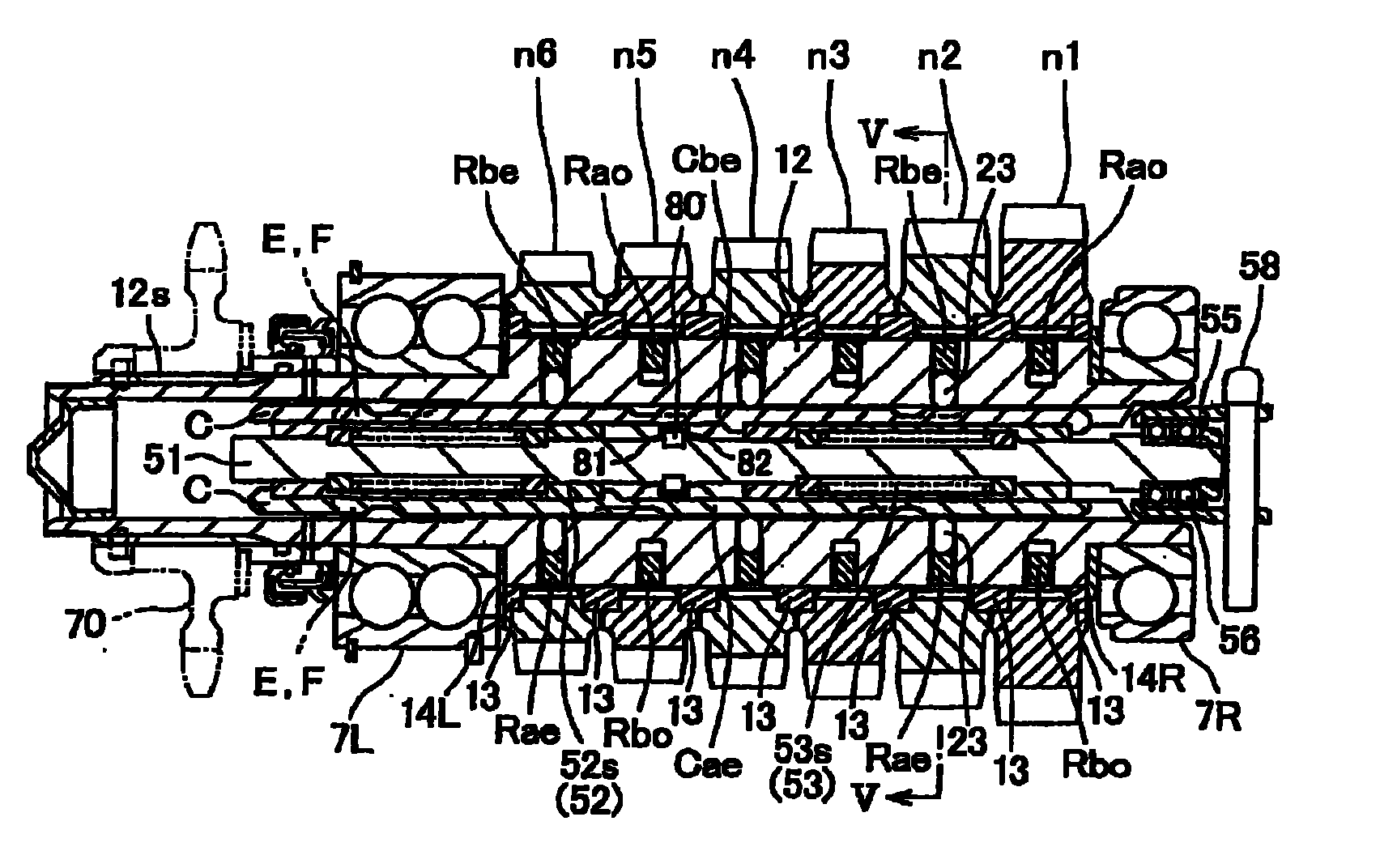

[0073] refer to Figure 1-17 , the present invention will be described below in which a multi-speed transmission 10 is provided in an internal combustion engine installed in a motorcycle.

[0074] figure 1is a cross-sectional view of the multi-stage transmission 10, such as figure 1 As shown, a multi-speed transmission 10 is arranged on a motor housing 1 which also covers the internal combustion engine.

[0075] The engine case 1 is constructed by combining the left engine case 1L and the right engine case 1R, wherein a transmission case 2 is formed by lateral division, and a main gear shaft 11 and an intermediate gear shaft 12 are rotatably supported on the transmission case 2, the gear shafts laterally arranged parallel to each other.

[0076] The main gear shaft 11 is rotatably supported on the side wall of the left engine housing 1L and the side wall 1RR of the right engine housing 1R through each bearing 3L, 3R, and passes through the right bearing 3R. A multi-disc fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com