Thermal treatment carburization charge tooling

A carbon furnace and tooling technology, which is applied to heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of laborious handling, small furnace loading, and high labor intensity, and achieve qualified carburizing quality and increased furnace loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

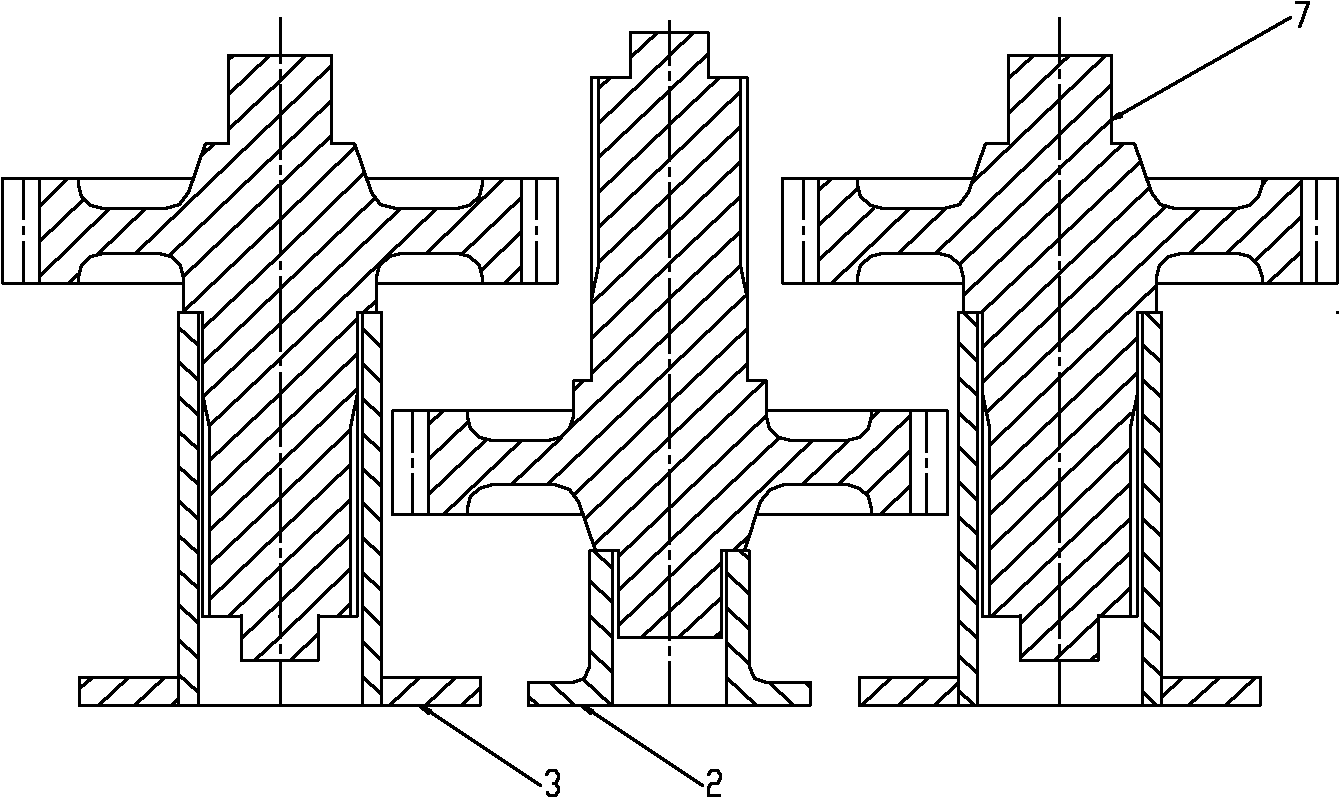

[0013] The engine power take-off output gear is ideally carburized and quenched vertically to reduce the amount of deformation. At the same time, in order to ensure uniform carburization and quenching of all parts of the gear, under the constraints of space and furnace weight, install as many gears as possible to reduce the weight of auxiliary tooling and its volume. The existing tooling is placed in one direction, which will inevitably cause the teeth to be on the same plane, which takes up a lot of space, and the thermal field in the furnace is unevenly distributed, which affects the carburizing and quenching quality of the gears.

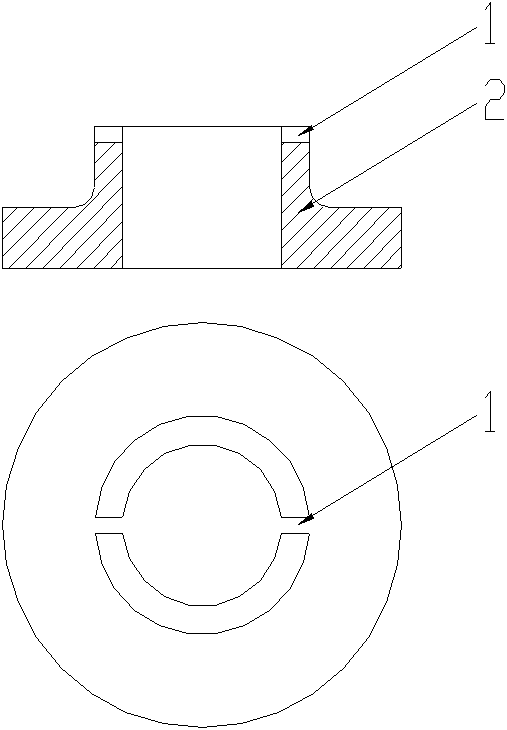

[0014] Such as figure 1 As shown, the tooling 2 is integrally processed, and the 4mm gap 1 on the upper part makes the carburizing atmosphere and quenching oil pass smoothly.

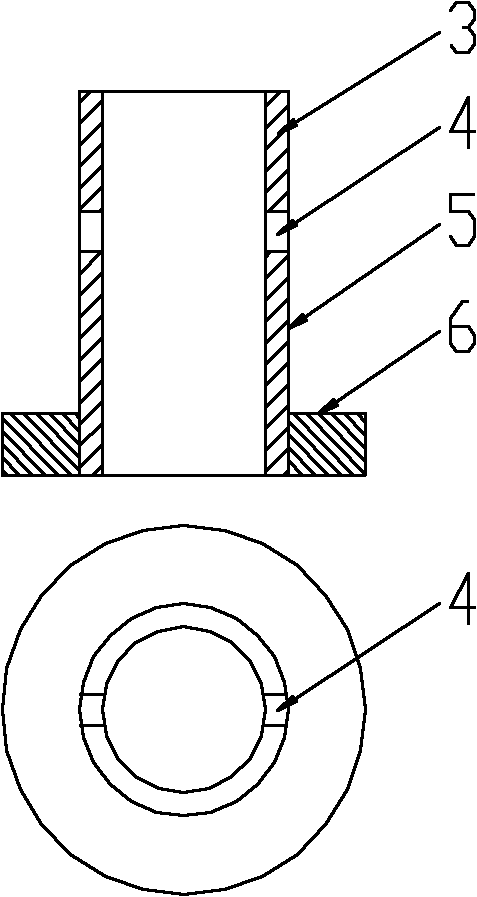

[0015] Such as figure 2 As shown, the tooling 3 is welded by the chassis 6 and the sleeve 5, and the hole 4 with a diameter of 8 mm in the middle of the sleeve 5 makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com