End mill with unequal helical angles

An end mill and helix angle technology, applied in the field of metal cutting, can solve the problems of small chip space at the bottom of the groove, poor strength and rigidity of the cutting edge, unfavorable chip curling and discharge, etc., to improve cutting efficiency and durability. , Improve the surface quality, strength and good chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

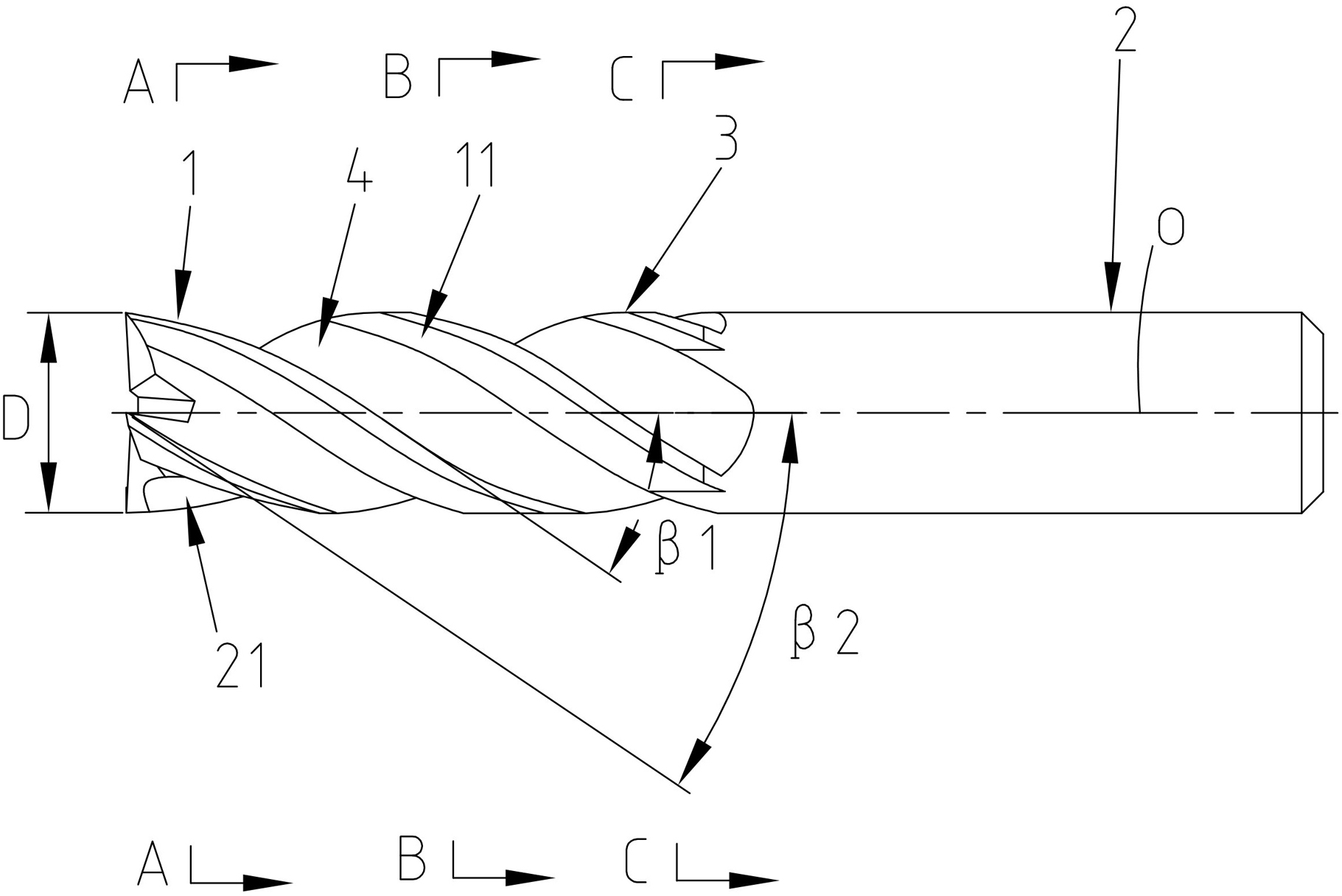

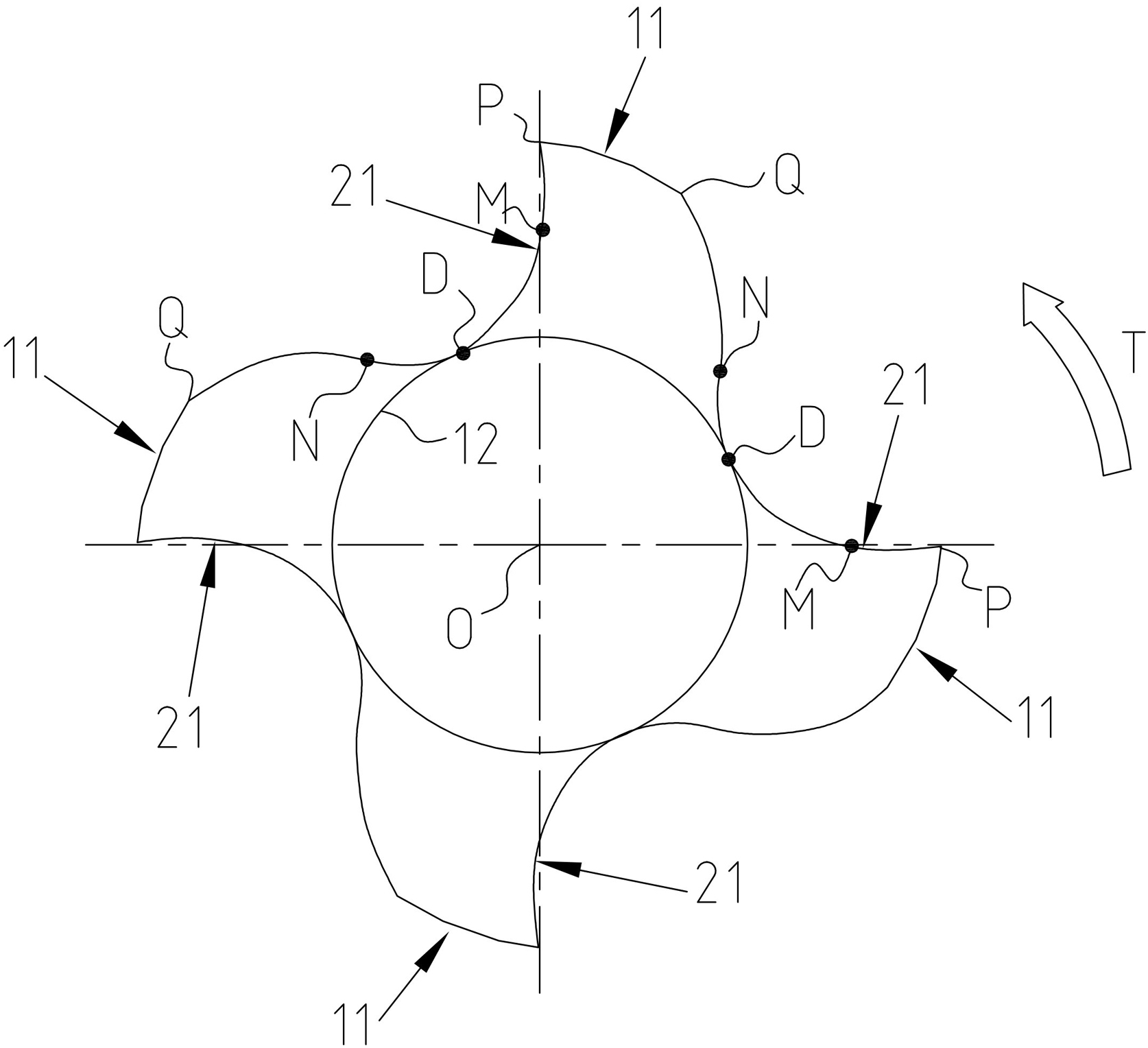

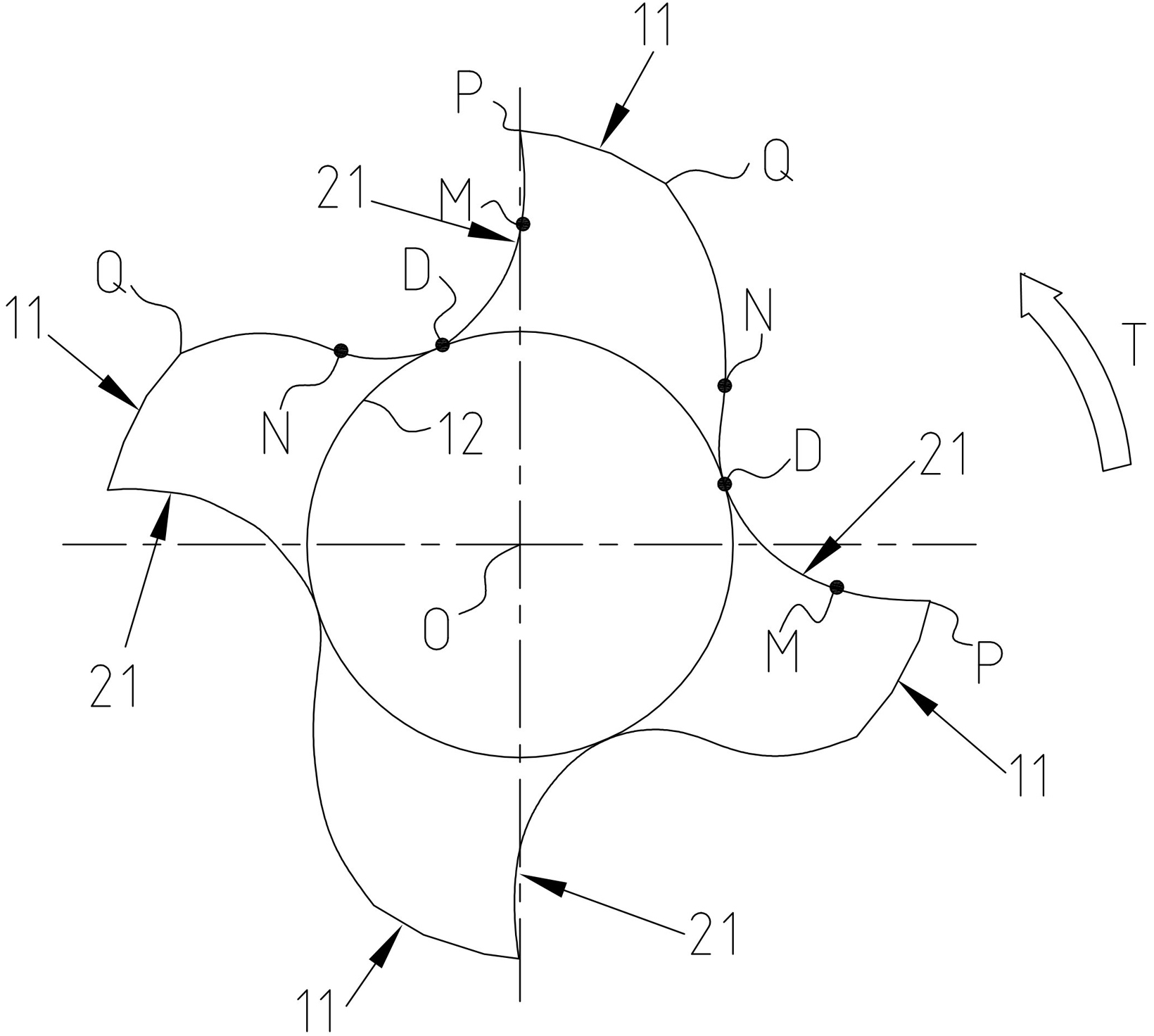

[0019] Figure 1 to Figure 4 An embodiment of the unequal helix angle end mill of the present invention is shown. The end mill is made of a cemented carbide material in a cylindrical shape. One end of the end mill is a cylindrical shank 2 and the other end is a cutting portion 1. The shank 2 is used to connect the machine tool spindle, and the machine tool spindle drives the end mill to rotate and cut the workpiece in the T direction. The entire cutting portion 1 is provided with a plurality of chip flutes 4 spirally extending from the bottom end to the shank 2. In this embodiment, there are four chip flutes 4, and the four chip flutes 4 are arranged at unequal intervals. The surface of each chip flute 4 facing the cutting rotation direction is the rake face 21. The rake face 21 intersects with the outer peripheral surface of the cutting portion 1 to form a peripheral edge 3, and the helix angle of at least one peripheral edge 3 is different from that of other peripheral edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com