Preparation method of novel PETG thermal contraction label film special for battery

A production method and heat shrinking technology, which is applied in the field of new PETG heat shrinkable battery special label film, can solve problems such as health hazards, poor temperature resistance, and shell corrosion, and achieve the effects of reducing pollution, superior performance, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

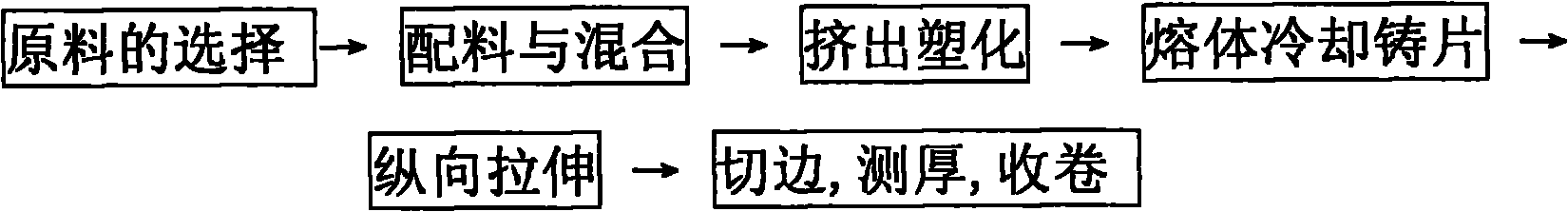

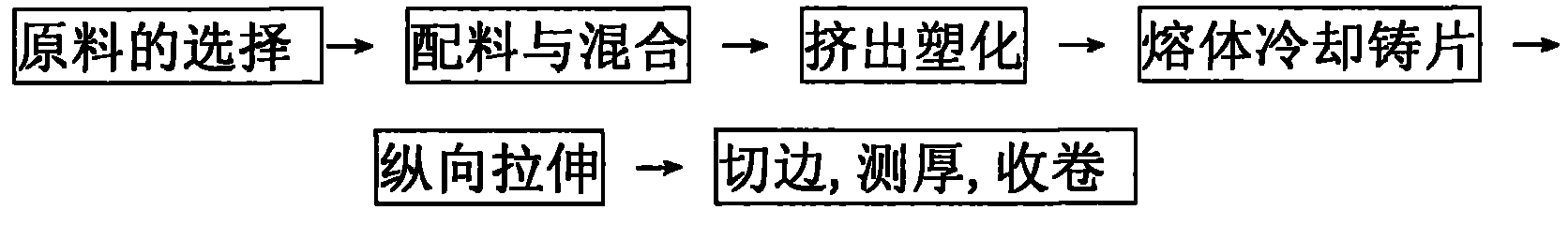

Method used

Image

Examples

Embodiment Construction

[0015] (1). Selection of homopolymerized PET raw materials:

[0016] It is mainly to choose the distribution range of molecular weight, which is very different from the general PET biaxially stretched film materials. Biaxially stretched PET film requires a narrower molecular weight distribution of PET raw materials, which is conducive to the formation of the subsequent stretching process. However, the special label film for heat-shrinkable PET with high temperature resistance is mainly due to the crystallization properties of homo-PET, so it is better to have a wider molecular weight distribution. The main reason is that low-molecular-weight homo-PET has better crystallization properties. The higher the degree of crystallinity in the special label film for heat-shrinkable batteries, the better the temperature resistance. The viscosity of homopolymerized PET is IV≥0.65, the molecular weight distribution can be wider (the content of terminal carboxyl groups is between 20-30), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com