Ocean ship tail gas denitration method by combination of air supply local discharging oxidation and sea water washing

A ship exhaust and discharge oxidation technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of high price, large volume, and increased power consumption, and achieve high prices, low prices, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

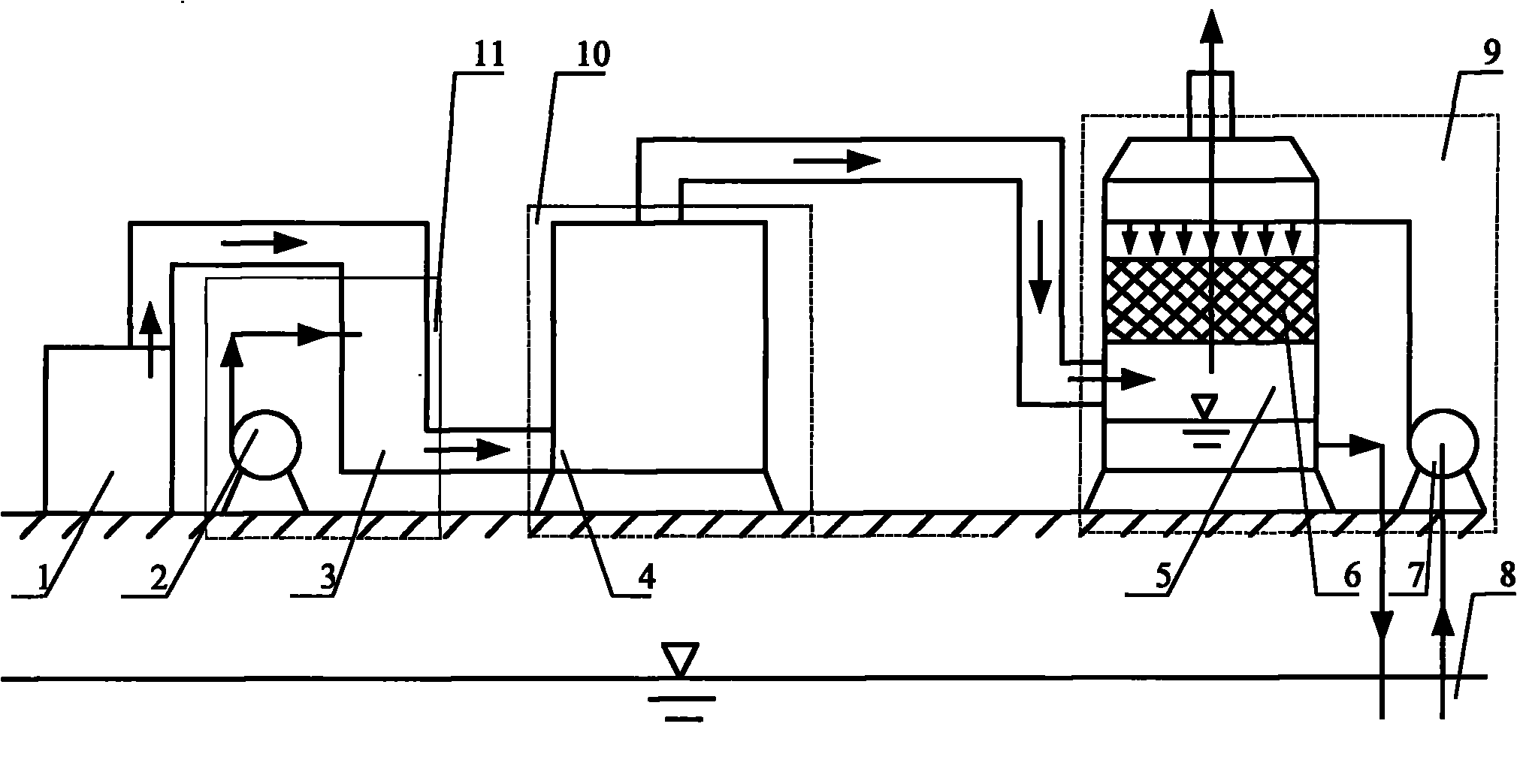

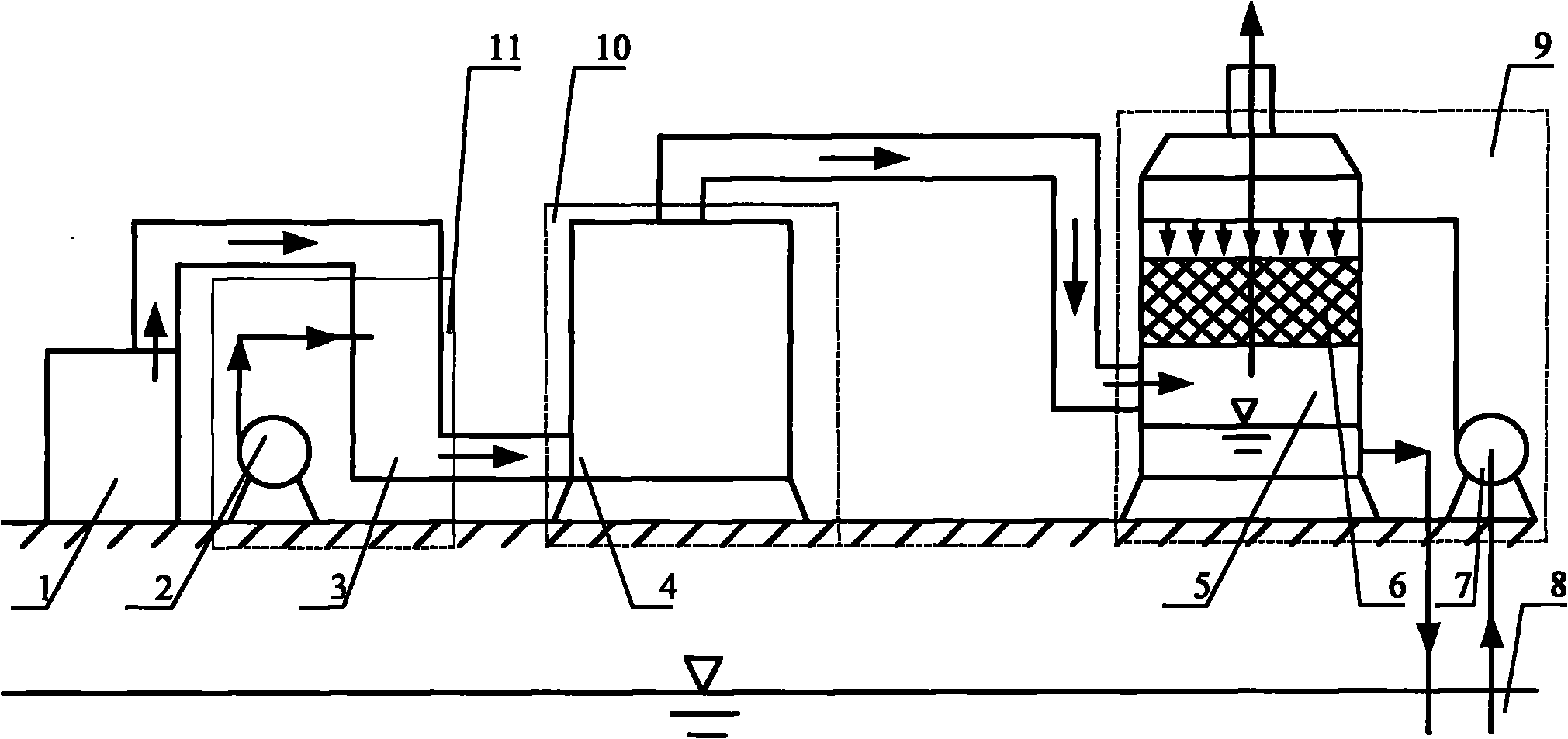

[0014] combined with figure 1 and one A kind of embodiment of the present invention is further described as follows to the method for denitrification of tail gas of ocean ships:

[0015] Such as figure 1 As shown, a method for denitrification of marine ship tail gas combined with air supplementation, in-situ discharge oxidation and seawater washing is composed of three steps in series: air supplementation, in-situ discharge oxidation and seawater washing, and will be carried out by using the method provided by the present invention accordingly. The exhaust gas denitrification system of marine ships is divided into gas supply area 11, in-situ discharge oxidation area 10 and seawater washing area 9, so that the exhaust gas generated by marine diesel engine 1 is in the order of air supply area 11, in-situ discharge oxidation area 10 and seawater washing area 9 Pass through in turn to complete the tail gas denitrification process.

[0016] The gas replenishing area 11 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com