Polymer fiber material, method of producing the same and filter for filtering fluid

A manufacturing method, polymer technology, applied in the direction of membrane filter, filtration separation, fiber treatment, etc., can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

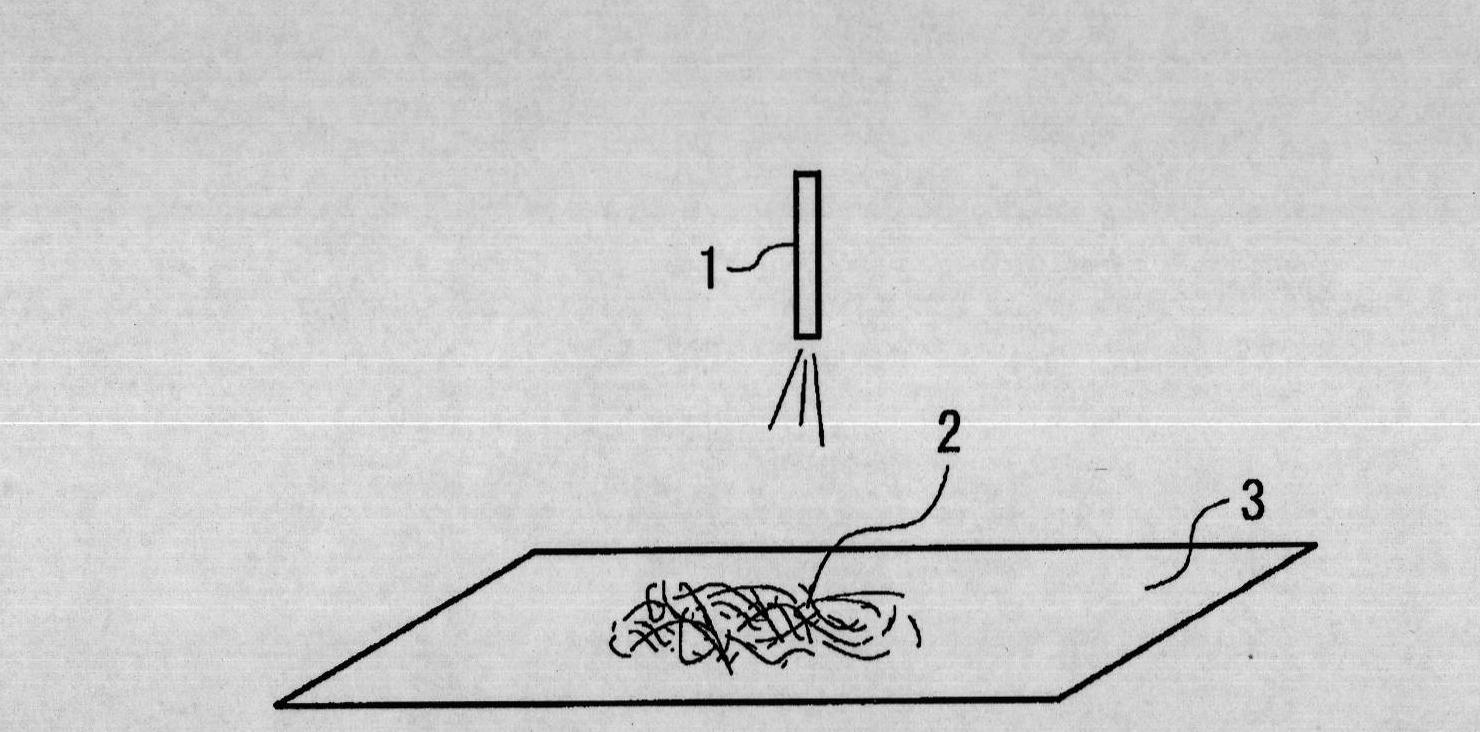

Method used

Image

Examples

Embodiment 1

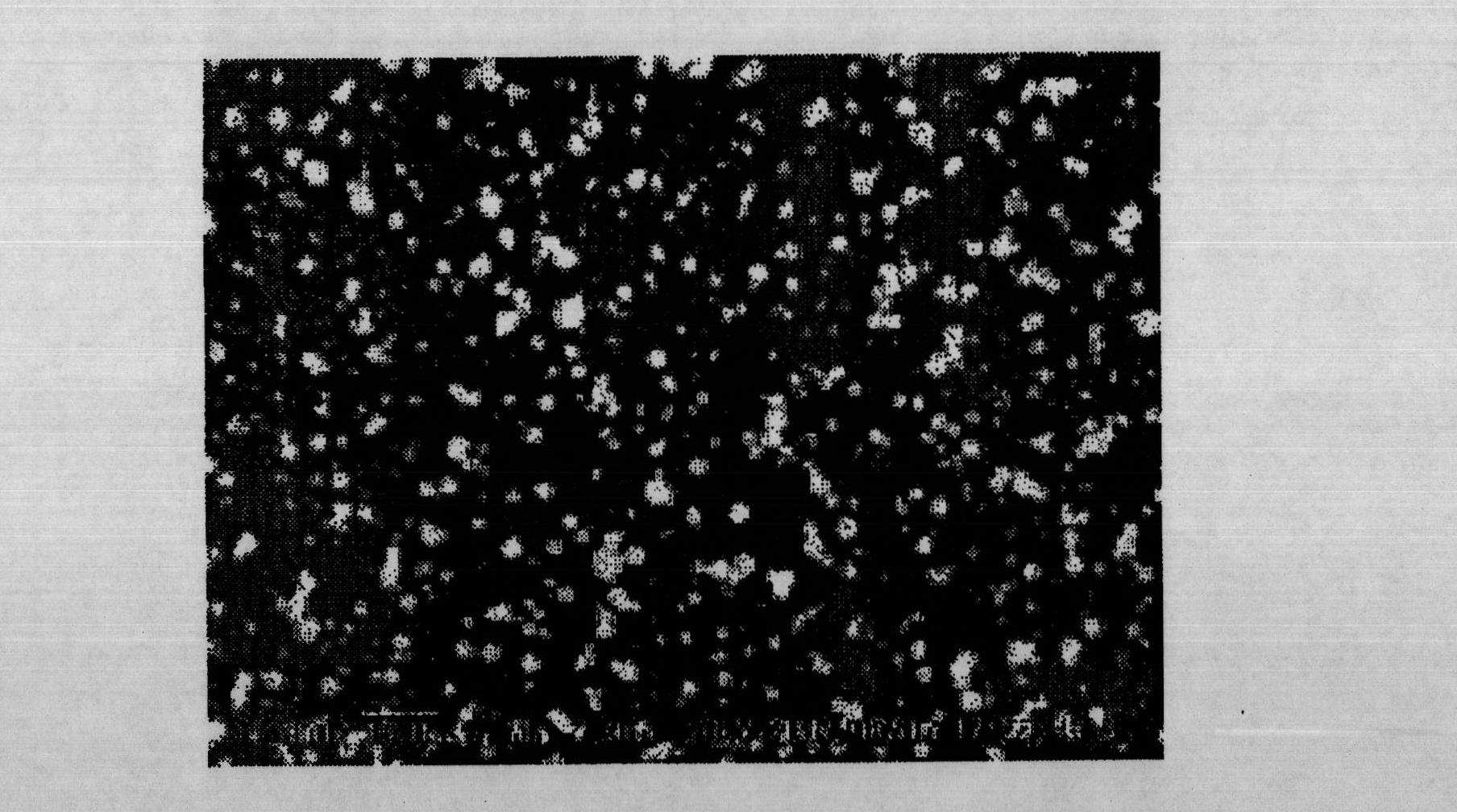

[0099] A solution containing 10% by weight of PVDF, 8.3% by weight of Nafion, 4.2% by weight of water, 4.2% by weight of 1-propanol, and 73.3% by weight of DMAc was prepared as a solution containing a non-electrolyte polymer and an electrolytic polymer. Try spinning it under the conditions. It should be noted that since this solution tends to gel, it is heated during spinning and kept at about 45°C. image 3 This is a photograph taken with an electron microscope at a magnification of 1000 to deposit platinum on the obtained fiber.

[0100]

[0101] Such as image 3 As shown, a fiber of 200 nm can be spun, and a hybrid polymer fiber body having a thickness of 50 μm including the fiber can be produced. And, by laminating the hybrid polymer fiber body in a planar shape, a nonwoven fabric flat film having a thickness of 2 mm can be produced.

Embodiment 2

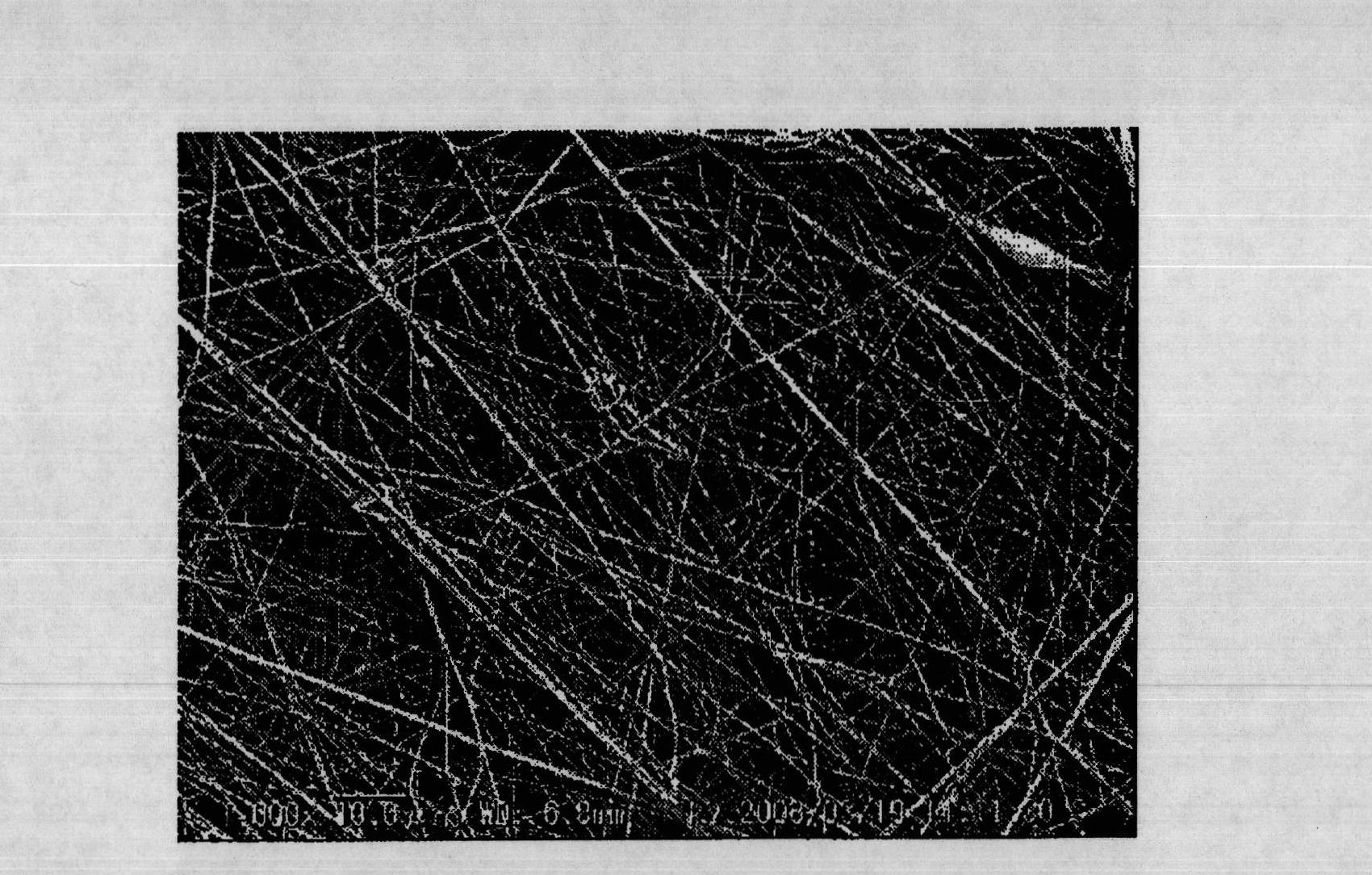

[0103] A solution containing 15% by weight of PVDF, 4.2% by weight of Nafion, 2.1% by weight of water, 2.1% by weight of 1-propanol, and 76.6% by weight of DMAc was prepared as a solution containing a non-electrolyte polymer and an electrolytic polymer. Try spinning it under the conditions. It should be noted that since this solution tends to gel, it is heated during spinning and kept at about 45°C. Figure 4 This is a photograph taken with an electron microscope at a magnification of 1000 to deposit platinum on the obtained fiber.

[0104]

[0105] Such as Figure 4 As shown, a fiber of 400 nm can be spun, and a hybrid polymer fiber body having a thickness of 50 μm including the fiber can be produced. And, by laminating the hybridized polymer fibers in a planar shape, a nonwoven fabric flat film having a thickness of 2 mm can be produced.

[0106] "Filtration Test of Dilute Metal Solution"

[0107] After the filters made of the nonwoven fabric flat membrane produced in ...

Embodiment 3

[0116] Add 40 mL of DMAc as a solvent having a higher boiling point than water to 50 mL of an electrolytic polymer solution of 20% by weight of Nafion, 40% by weight of 1-propanol, and 40% by weight of water, and keep at a temperature of 100°C for 1 hour, and then at a temperature of 80°C. Keep at 60°C for 2 hours and 8 hours at 60°C to slowly evaporate water and 1-propanol whose boiling point is lower than DMAc, and prepare Nafion 20% by weight, DMAc 79-80% by weight, 1-propanol and water as An electrolytic polymer solution (second solution) of 1% by weight or less. The δH at this time was 5.0.

[0117] This second solution was mixed with a non-electrolyte polymer solution (first solution) of 20% by weight of PVDF and 80% by weight of DMAc at a weight ratio of 5:5 to prepare PVDF 10% by weight as a solution containing a non-electrolyte polymer and an electrolytic polymer. %, Nafion 10% by weight, DMAc 79-80% by weight mixed solution

[0118] Spinning was performed under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com