Glass melting furnace

A glass melting furnace and melting furnace technology, applied in glass furnace equipment, glass production, glass manufacturing equipment and other directions, can solve problems such as expensive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

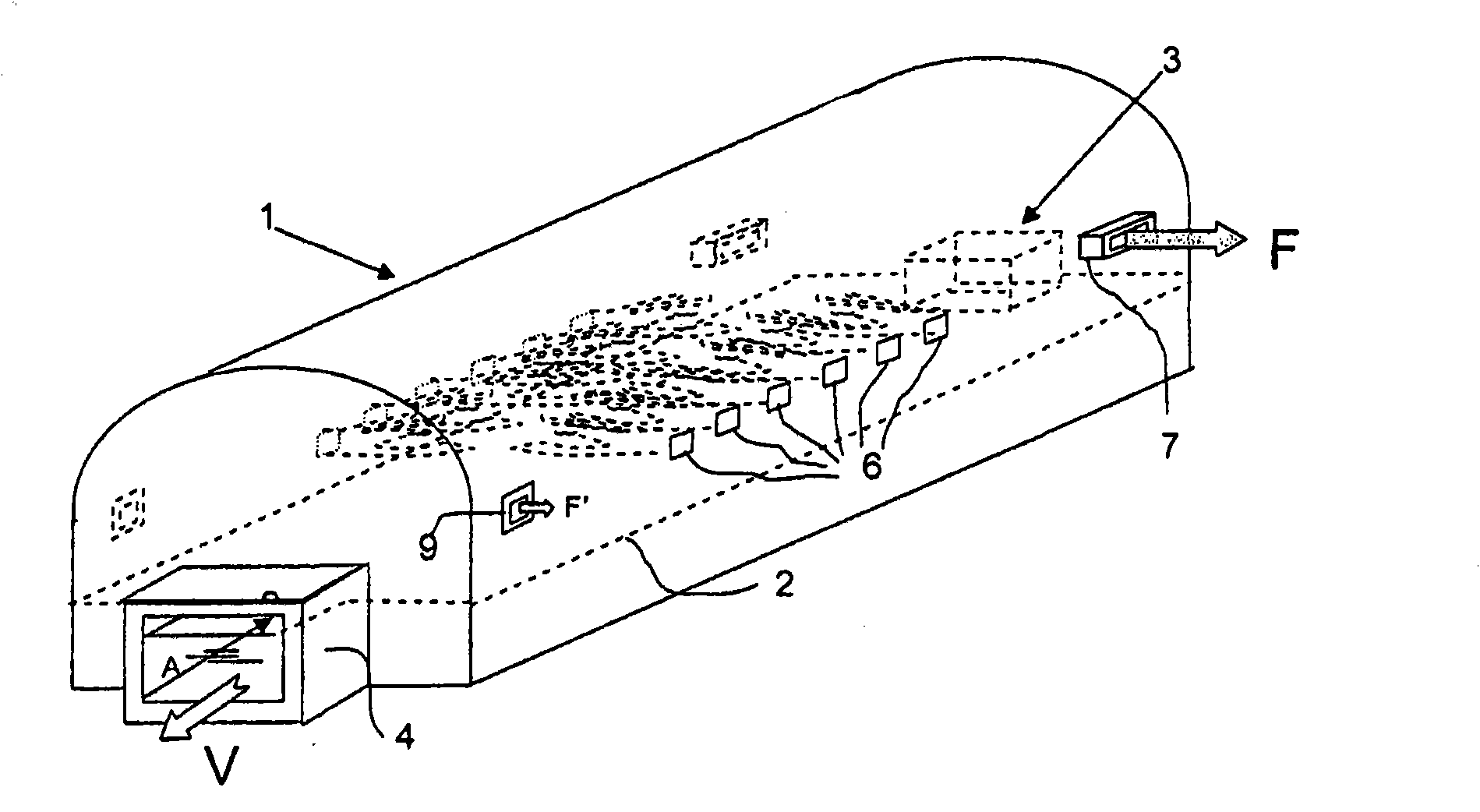

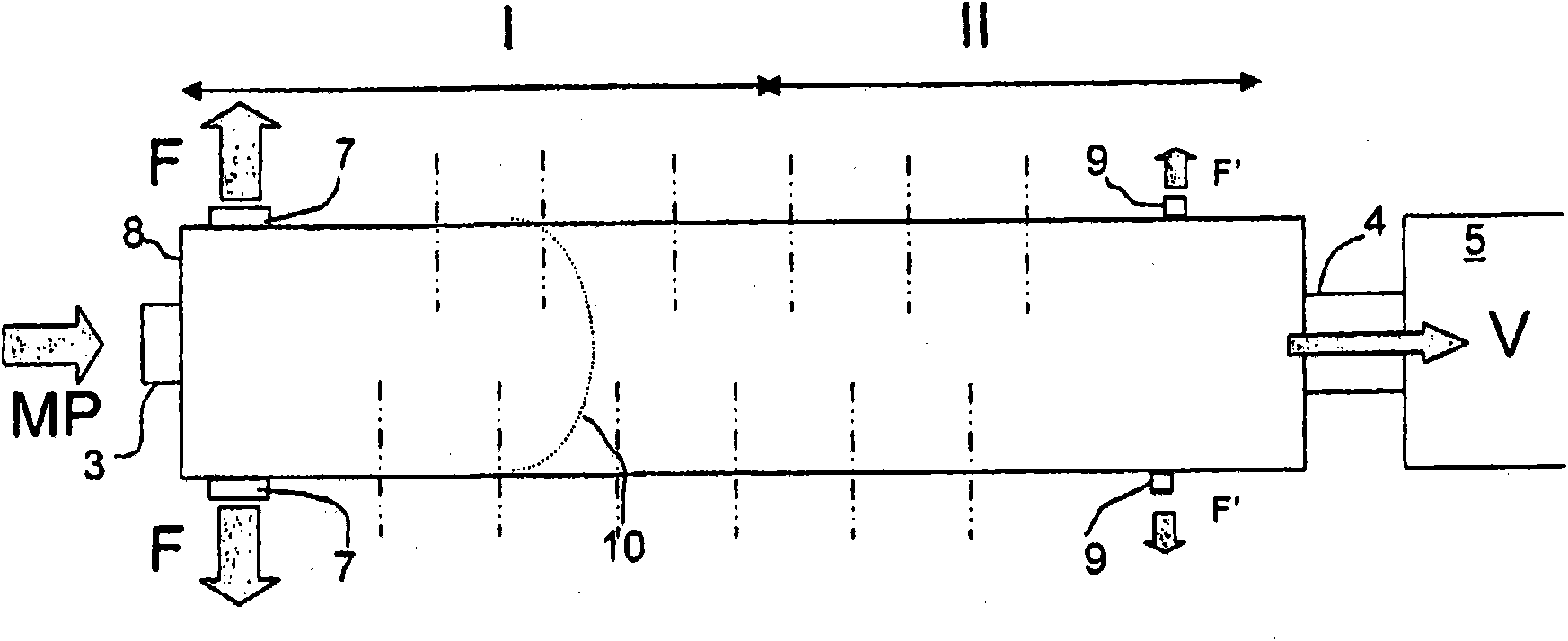

[0088] figure 1 The furnaces shown in are of the type used for bulk glass production, such as those that use suspended glass technology for feeding flat glass. This type of furnace can continuously produce up to 1000 tons / day of glass. To achieve these properties, the furnace must have power up to 60MV.

[0089] The furnace 1 comprises a pool arranged in a closed chamber. The assembly is constructed of a refractory material that is resistant to high temperatures, corrosion by exhaust gases, and corrosion by molten material. The height of the molten bath in the pool is indicated by the dashed line 2 .

[0090] The furnace is fed raw material at one end of it. The opening through which the raw material is charged into the furnace is shown at 3 . In practice, in order to facilitate distribution over the surface of the molten bath, multiple charging points are usually provided. The output of the molten glass, indicated by the arrow V, takes place at the opposite end through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com