Jet cooling device for heat treatment furnace

A technology of cooling device and heat treatment furnace, which is applied in the direction of heat treatment equipment, quenching device, quenching agent, etc., can solve the problem that the cooling speed cannot be realized, and achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

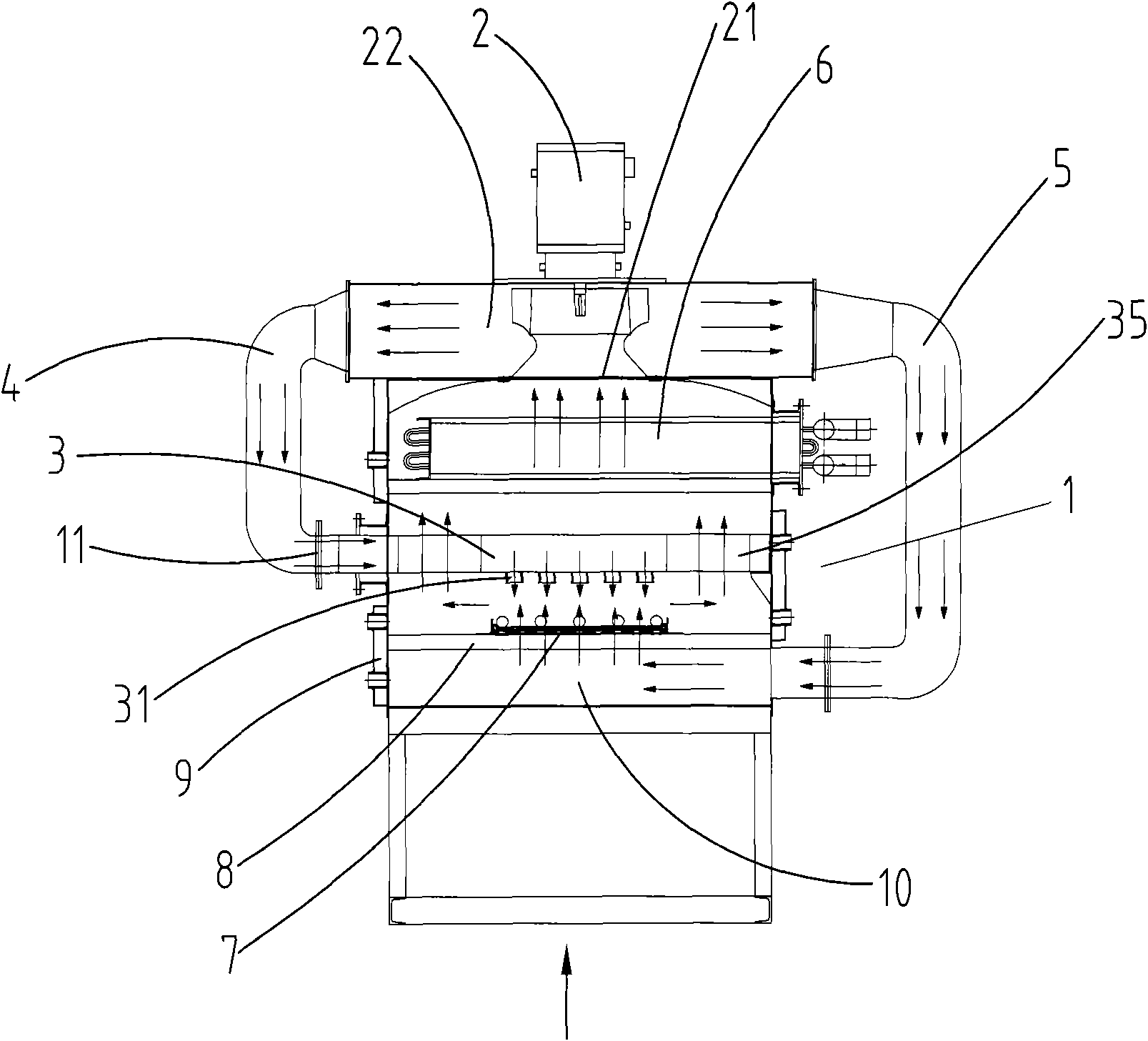

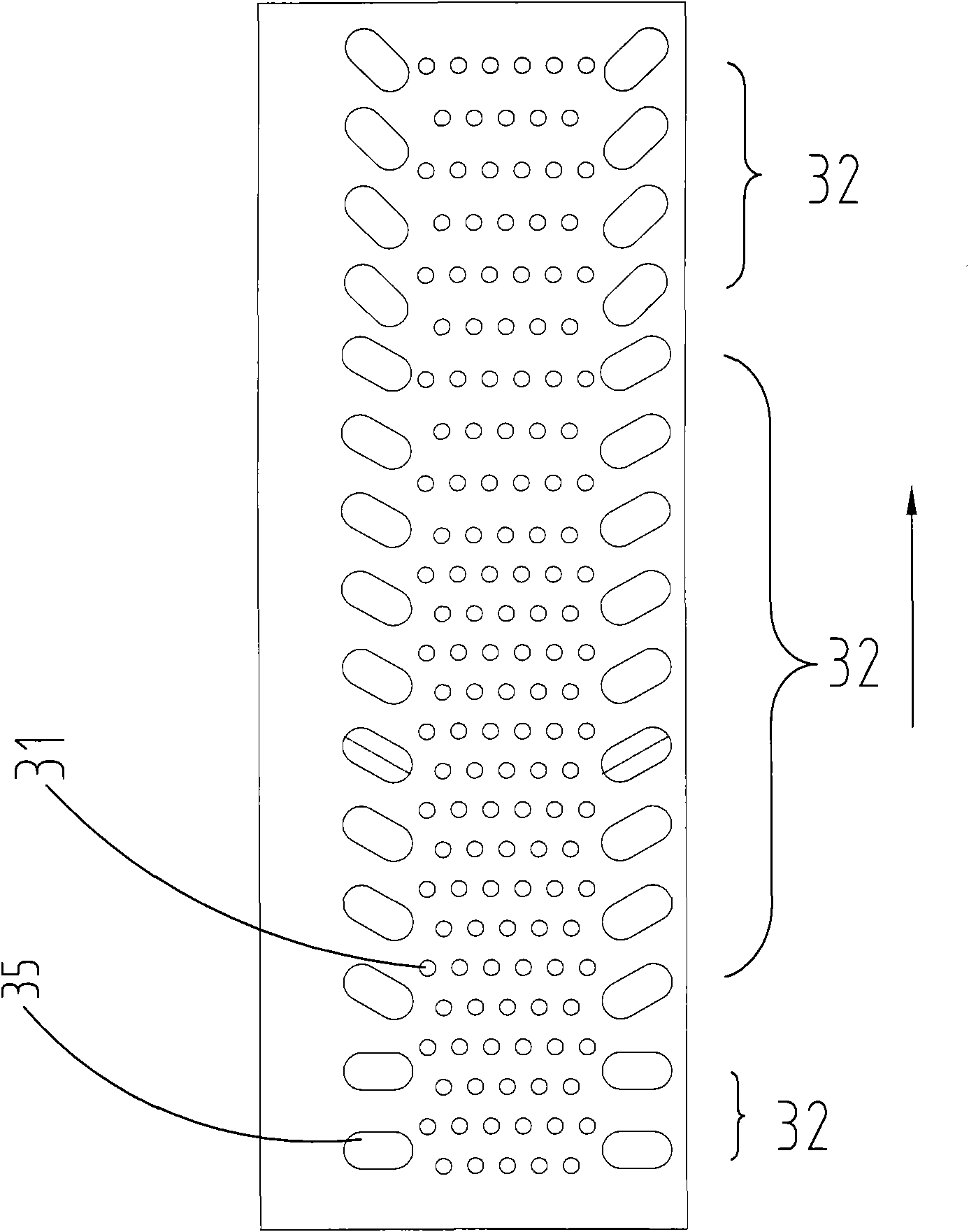

[0017] like Figures 1 to 3 As shown, the jet cooling device for a heat treatment furnace according to this embodiment includes a circulating fan 2 with an air inlet 21 and an air outlet 22, an air cooling chamber 1 whose upper part is communicated with the air inlet 21 of the circulating fan 2, and is arranged in the air cooling chamber 1. A carrier 8 for placing workpieces in the chamber 1, a heat exchanger 6 arranged in the air-cooled chamber 1 and located above the carrier 8, an air blower 3 arranged in the air-cooled chamber 1 and located above the carrier 8, both ends The first channel 4 communicated with the air outlet 22 of the circulating fan 2 and the air spray body 3 respectively, and the second channel 5 respectively communicated with the air outlet 22 of the circulating fan 2 and the bottom of the air cooling chamber 1 at both ends.

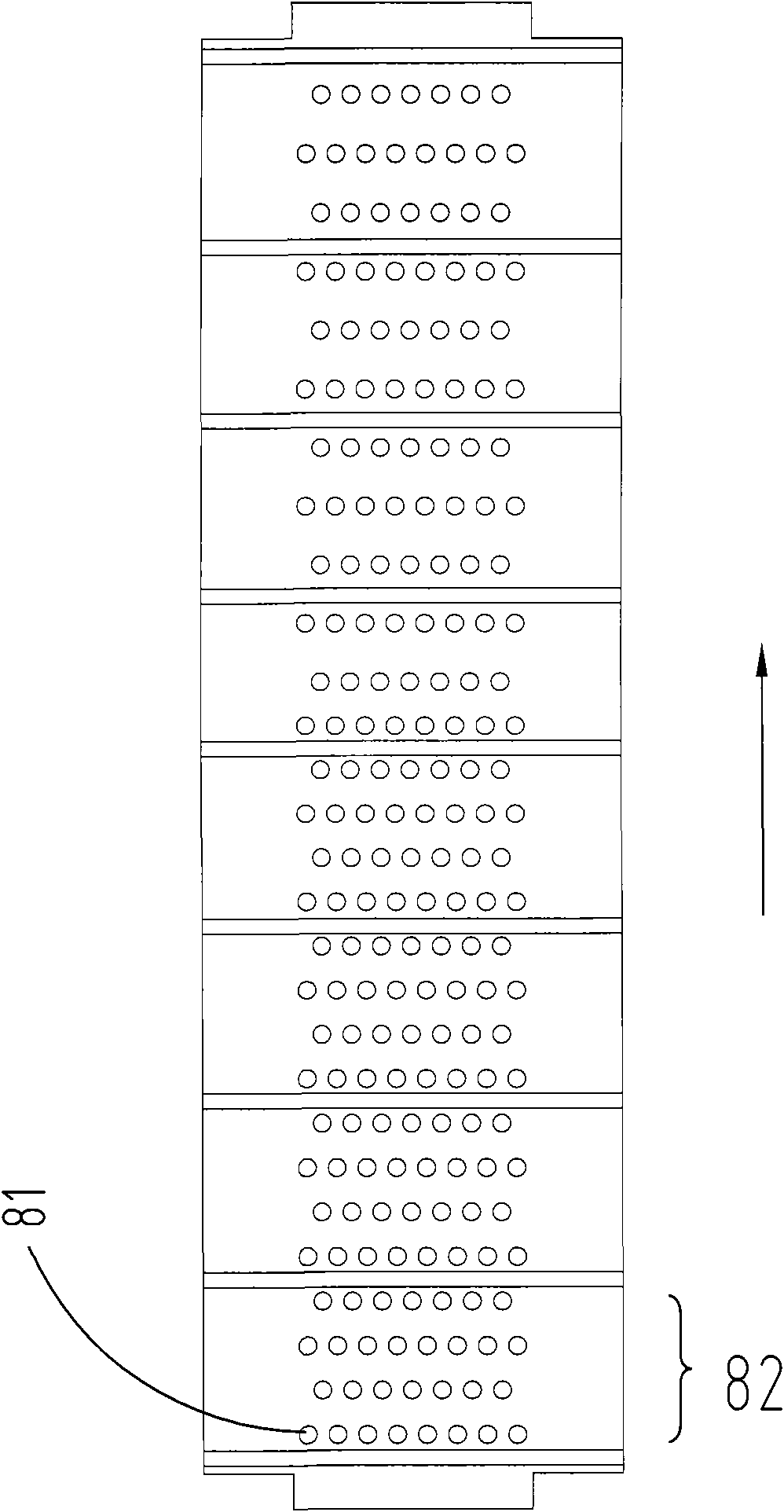

[0018] The bearing platform 8 divides the air-cooling chamber 1 into two upper and lower spaces, on which a conveyor belt 7 driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com