Complex enzyme formula for improving extraction rate of sodium alginate and application

A sodium alginate and extraction rate technology, applied in the direction of enzymes, lyases, hydrolases, etc., can solve the problems of difficult to crack cell walls and achieve the effect of easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] 2. The preparation method of the present invention is as follows: the raw material enzymes are pretreated respectively, and then put into an automatic mixer for compounding according to the proportion, and then the enzyme activity is measured and packaged quantitatively to become a product.

[0019] 3. The use method of the present invention: remove impurities from kelp or sargassum, add compound enzyme after crushing, stir evenly, add in a ratio of 5 / 1000 to 5 / 10,000, enzymatically hydrolyze 1- 6h, after the end of enzymatic hydrolysis, extract according to the normal process.

[0020] 4, process condition of the present invention:

[0021] Action temperature: 15-60°C (or room temperature) pH value: 4.0-9.0

[0022] Action time: 1-6h Addition amount: 500g-5000g tons of material

[0023] 5. Application effect:

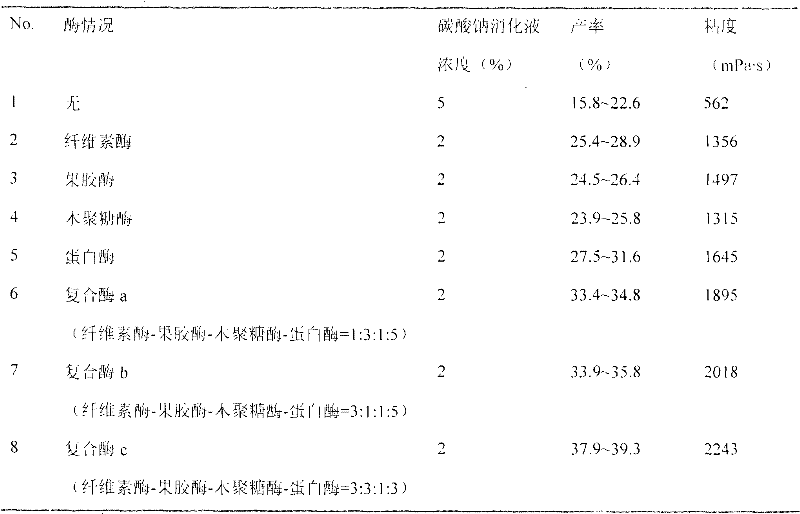

[0024] Application of the present invention utilizes the biological method to essentially solve the fatal problems of low extraction yield and low viscosity ...

Embodiment 1

[0030] Embodiment 1: the specific formula of the present invention is as follows (content is the weight percentage of composition): protease 50%, cellulase 30%, pectinase 10%, xylanase 10%.

[0031] The preparation method is as follows: the raw material enzymes are subjected to pretreatment respectively, filtered by a microfiltration membrane, then mixed in an automatic mixer in proportion, filtered through a fine filtration membrane, and quantitatively filled to become a product.

Embodiment 2

[0032] Embodiment 2: The specific formula of the present invention is as follows (the content is the composition of weight percentage): 30% of protease, 30% of cellulase, 30% of pectinase, 10% of xylanase. The preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com