Piston ring material for internal combustion engine

一种活塞环、内燃机的技术,应用在活塞环、机械设备、发动机元件等方向,能够解决差耐擦伤性等问题,达到贡献大、避免结构控制、优异自润滑性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

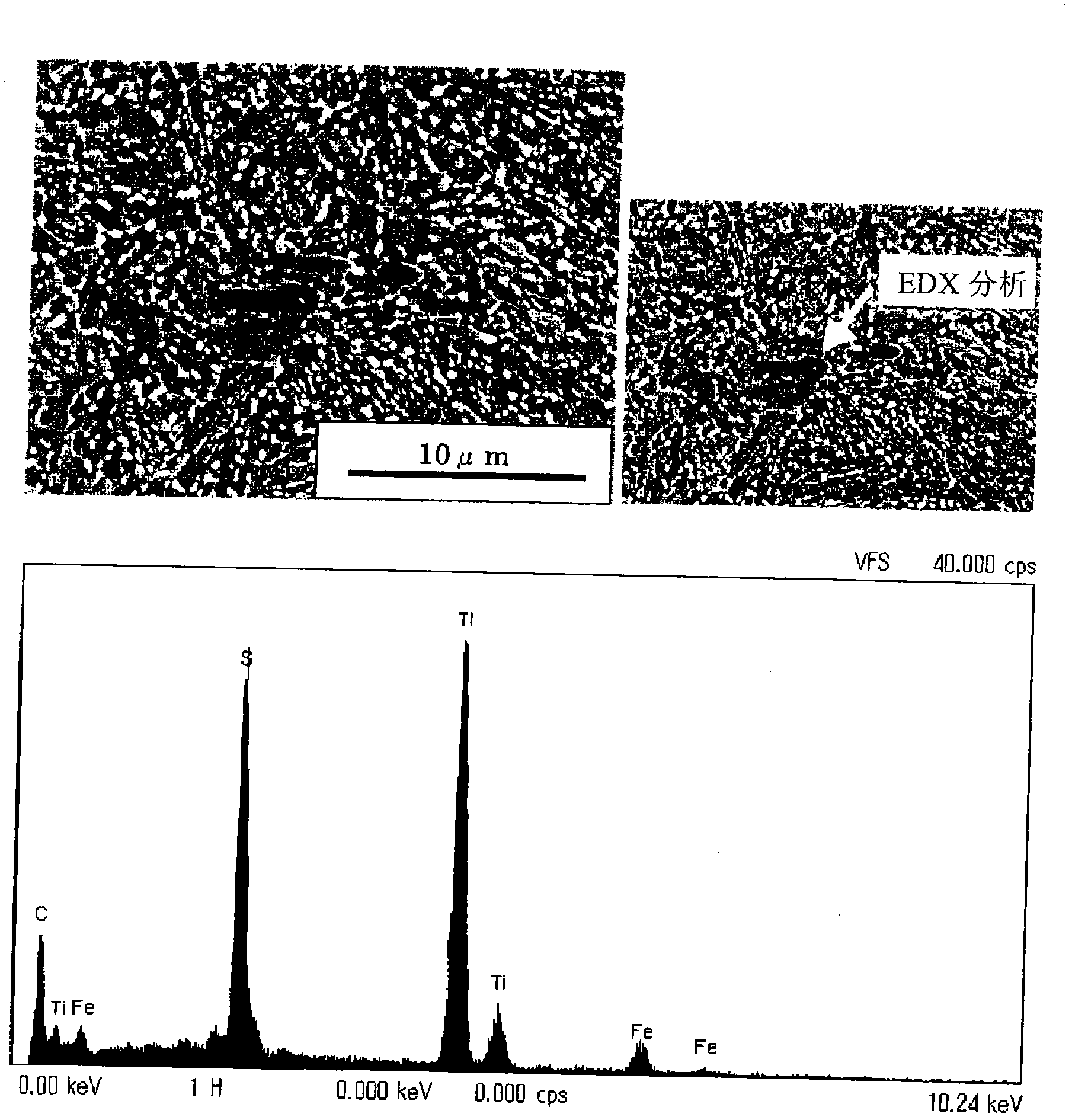

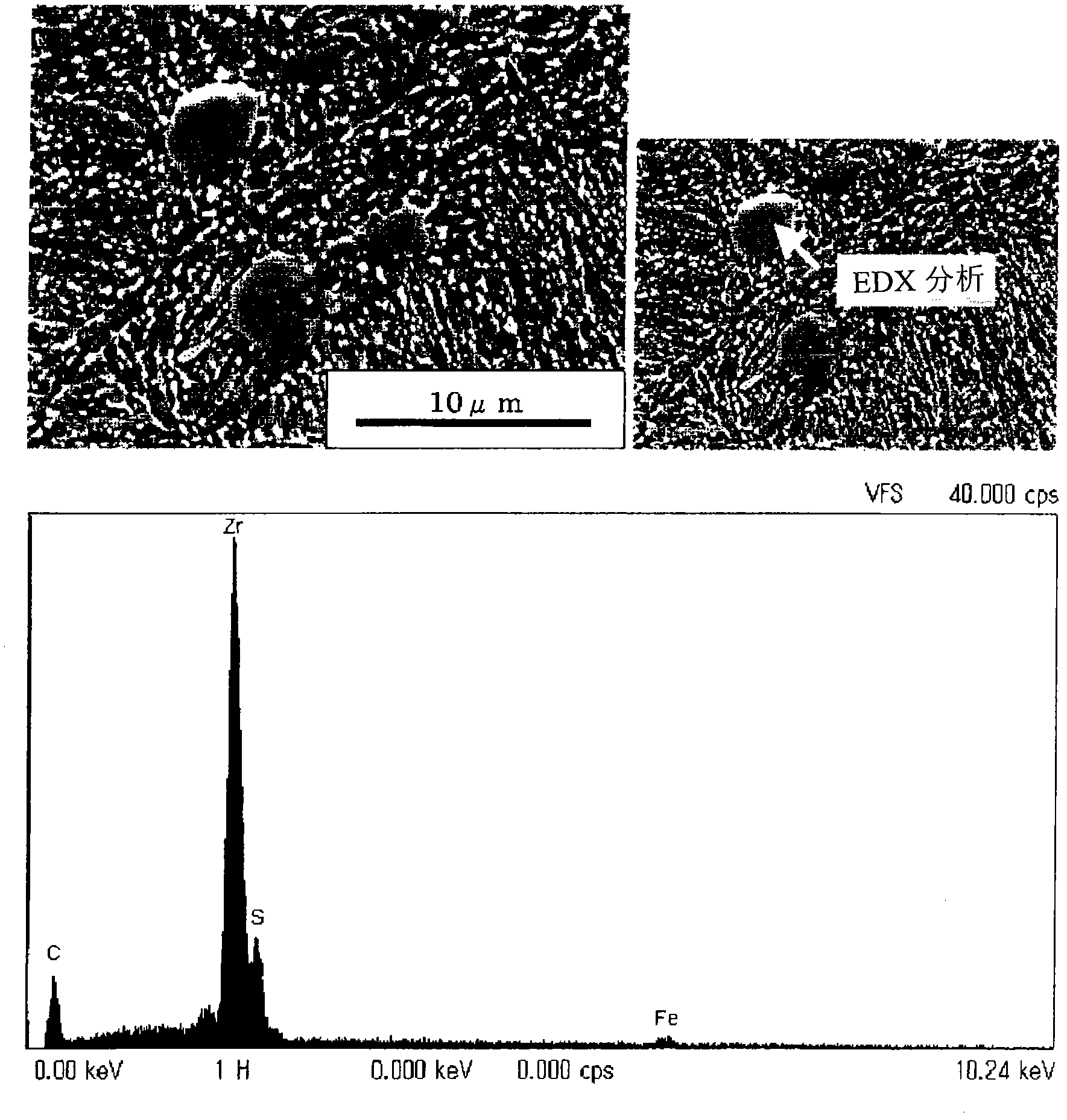

[0053] 10 kg of an ingot having a predetermined composition was prepared by melting in a vacuum induction melting furnace. Table 1 shows the chemical compositions of Materials 1 to 9 according to the present invention and Comparative Materials 11 to 14. For those with added titanium, zirconium, the ratio of titanium, zirconium to sulfur is also shown.

[0054]

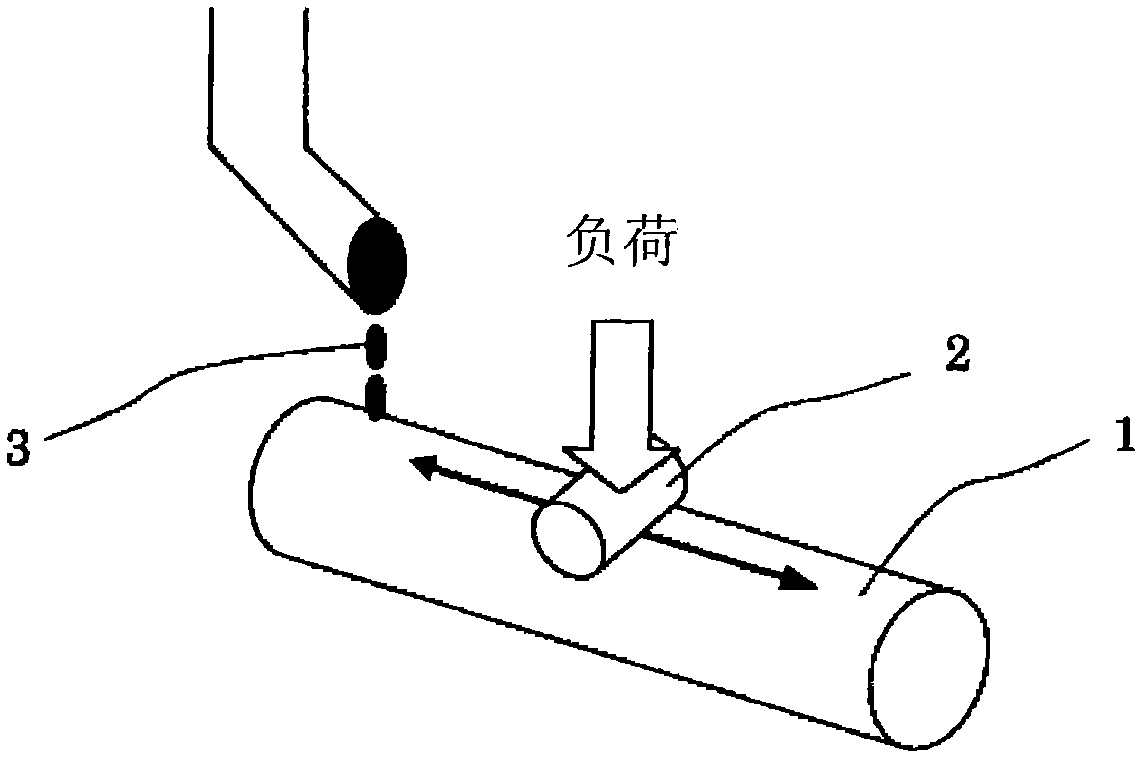

[0055] Next, the ingot was hot worked to form a 15 mm square rod, and the material was annealed. A part of the obtained annealed material was processed into a shape of a specimen for a tensile test having a parallel portion length of 45 mm and a parallel portion diameter of 7 mm. The samples were subjected to a tensile test for evaluating the drawing workability and rolling workability of the wire. The results are shown in Table 2. Table 2 demonstrates that the material according to the invention has a reduction of area after annealing of not less than about 40%, indicating good cold workability. Even if a part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| section shrinkage | aaaaa | aaaaa |

| section shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com