Pneumatic radial tire for heavy load

A technology for radial tires and treads, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc., and can solve the problems of degraded tread contact surface wear resistance, reduction, groove bottom cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

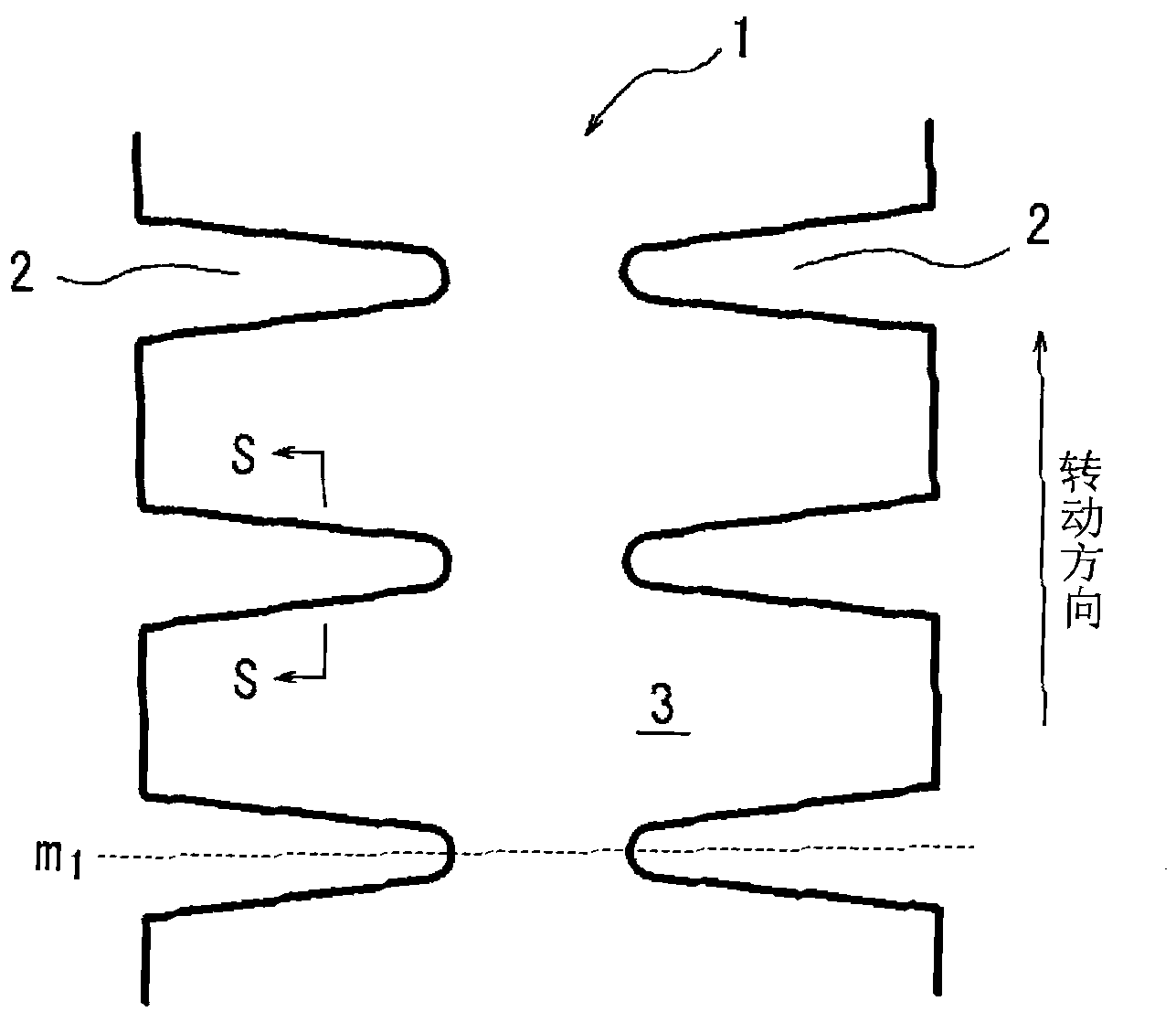

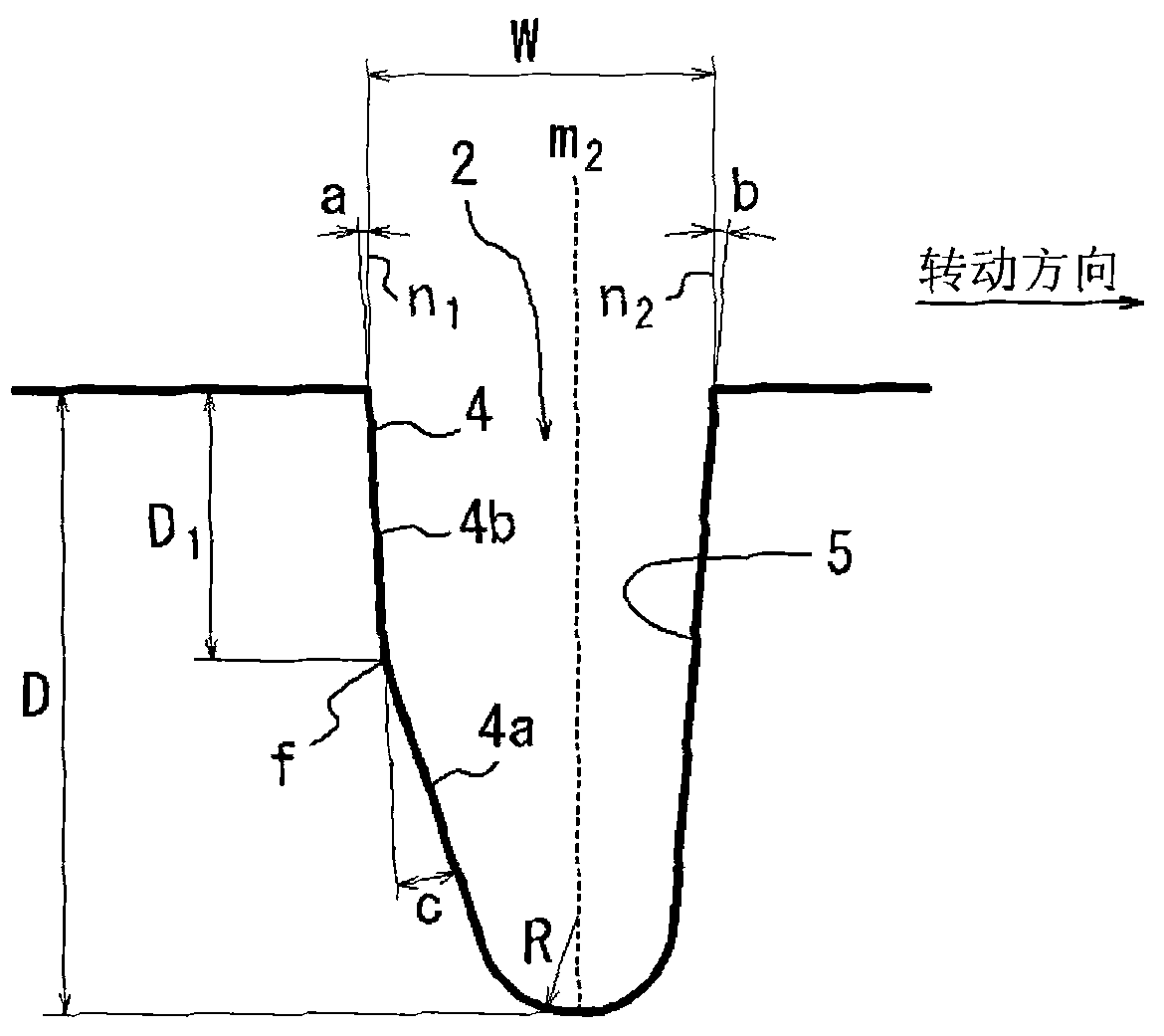

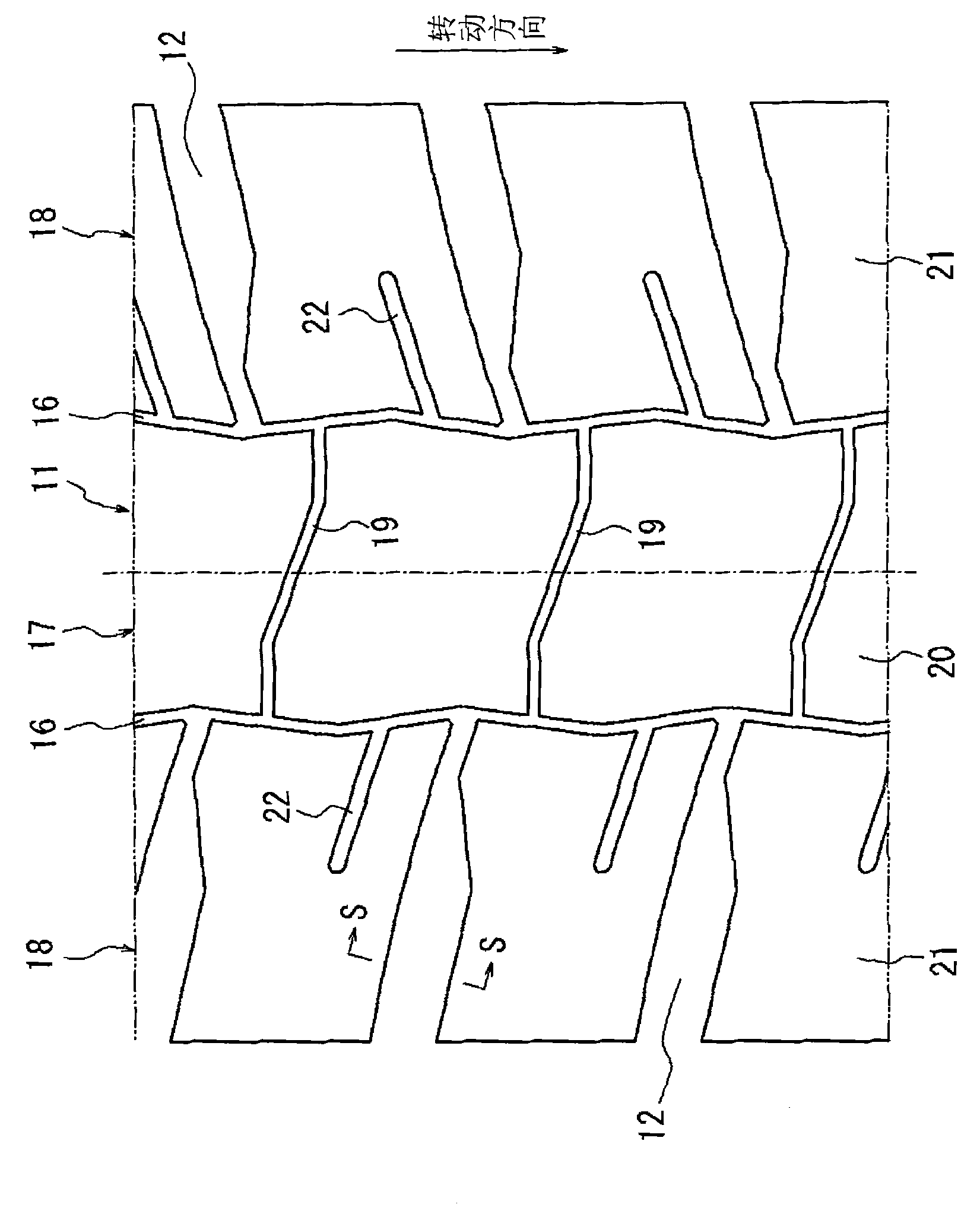

[0064] prepared respectively with figure 2 and image 3 Block pattern of the construction shown and a radial tire of size 46 / 90R57. For each of the Example tires 1 and 2 according to the present invention and the Comparative example tire in which the characteristics of the tires were changed as shown in Table 1, the sliding amount of the kick-out end portion of the block was measured.

[0065] Since the Comparative Example tires required no change from the Example tires except that the groove walls of the lug grooves should have a conventional structure, the Comparative Example tires were prepared in substantially the same manner as the Example tires.

[0066] Table 1

[0067]

[0068] Each of the Example tires 1 and 2 and the Comparative Example tire was fitted with a rim of 1.45 (m)×0.74 (m) (57 (inch)×29 (inch)) and inflated under an internal pressure of 700 kPa. Each tire was rotated with a load mass of 62000 kg applied thereto, and the amount of sliding of the kick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com