Panel quality virtual measurement method and system for TFT-LCD etching process

A panel and process technology, applied in the field of virtual measurement of panel quality, can solve the problems of not being able to understand the impact of panel quality and finding the key factors of variation, and achieve the effect of reducing complexity and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

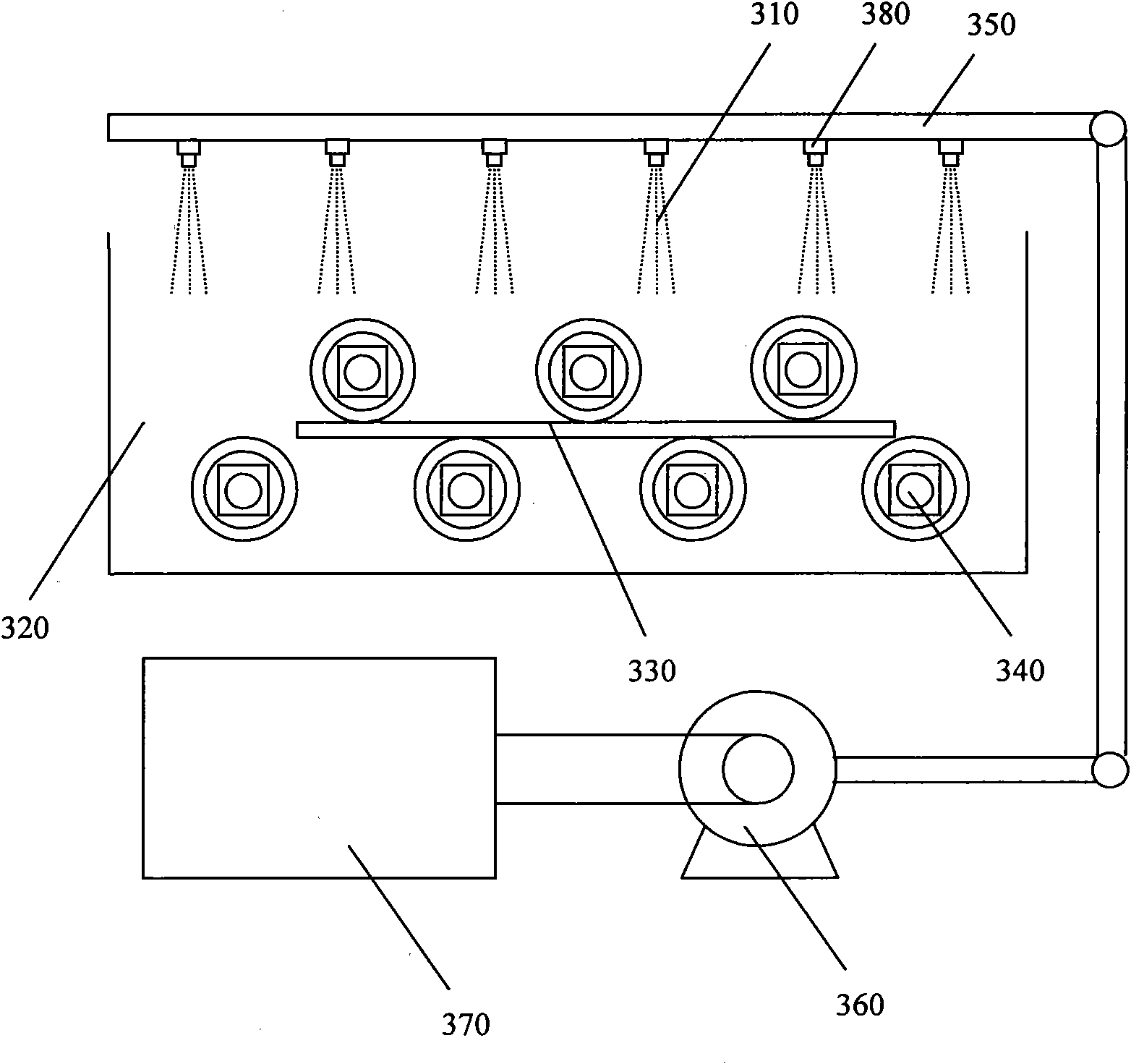

[0055] refer to image 3, when the system of the present invention is implemented, it consists of etching tank 320, acid solution 310, nozzle device 380, liquid supply device 350, delivery pump 360, storage tank 370, and delivery device 340, etc. The panel 330 is placed on the conveying device 340, and the acid liquid of 39°C to 44°C is sprinkled on the panel 330 from the nozzle of the spray head device 380, and the panel 330 is swung left and right by the conveying device 340, so that it fully reacts with the acid liquid 310, and then Atoms on the surface of the film are removed for etching purposes. It can be seen from the figure that the etching effect is directly related to the etching time, the spraying pressure of the flushing, the temperature of the acid solution and the consumption process of the acid solution. Among them, the etching time, reaction temperature, spraying pressure, etc. can be obtained directly by means of relevant instruments, but the consumption of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com