Zero temperature coefficient optical wave plate and polarization state converter

A temperature coefficient and polarization state technology, applied in the direction of optical waveguide light guide, optical waveguide coupling, instrument, etc., can solve the problems of not making full use of the best function of the system, wave plate delay phase deviation, adding additional noise, etc., to reduce the system cost, improve work efficiency, and simplify the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

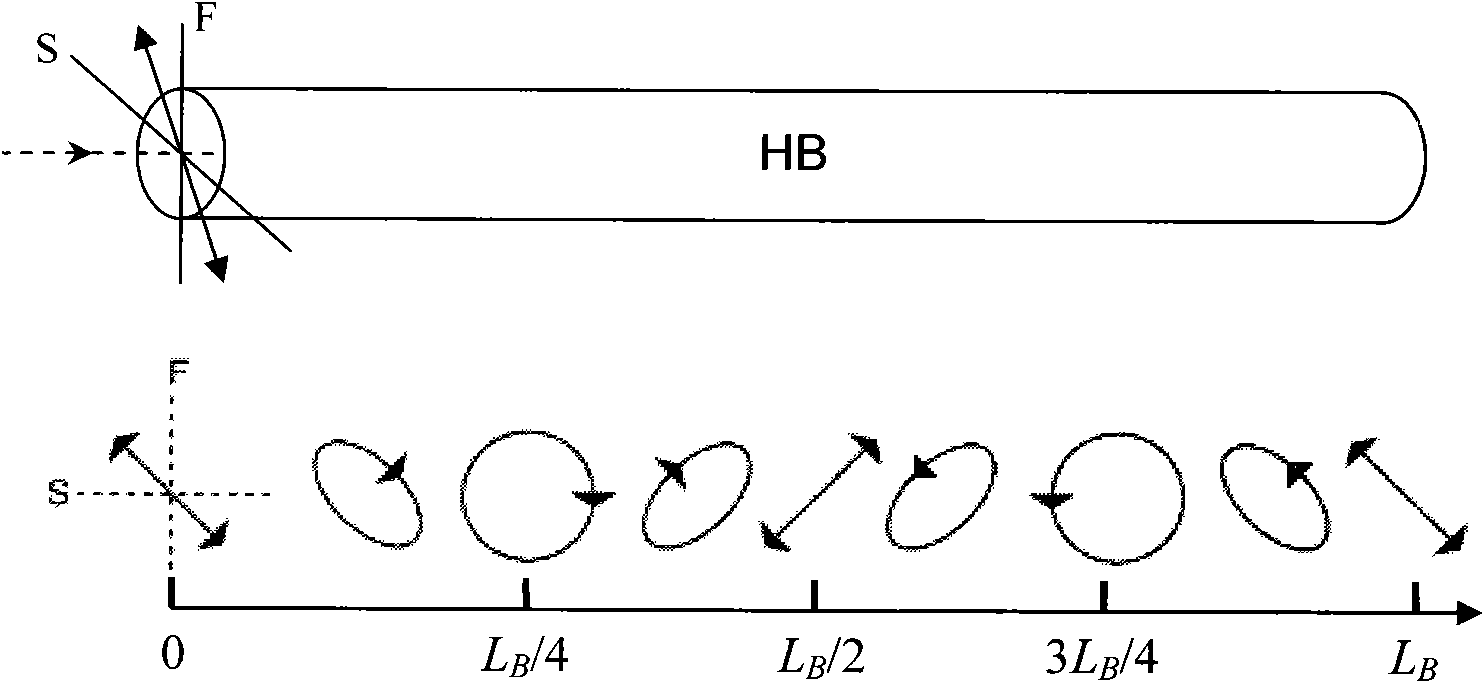

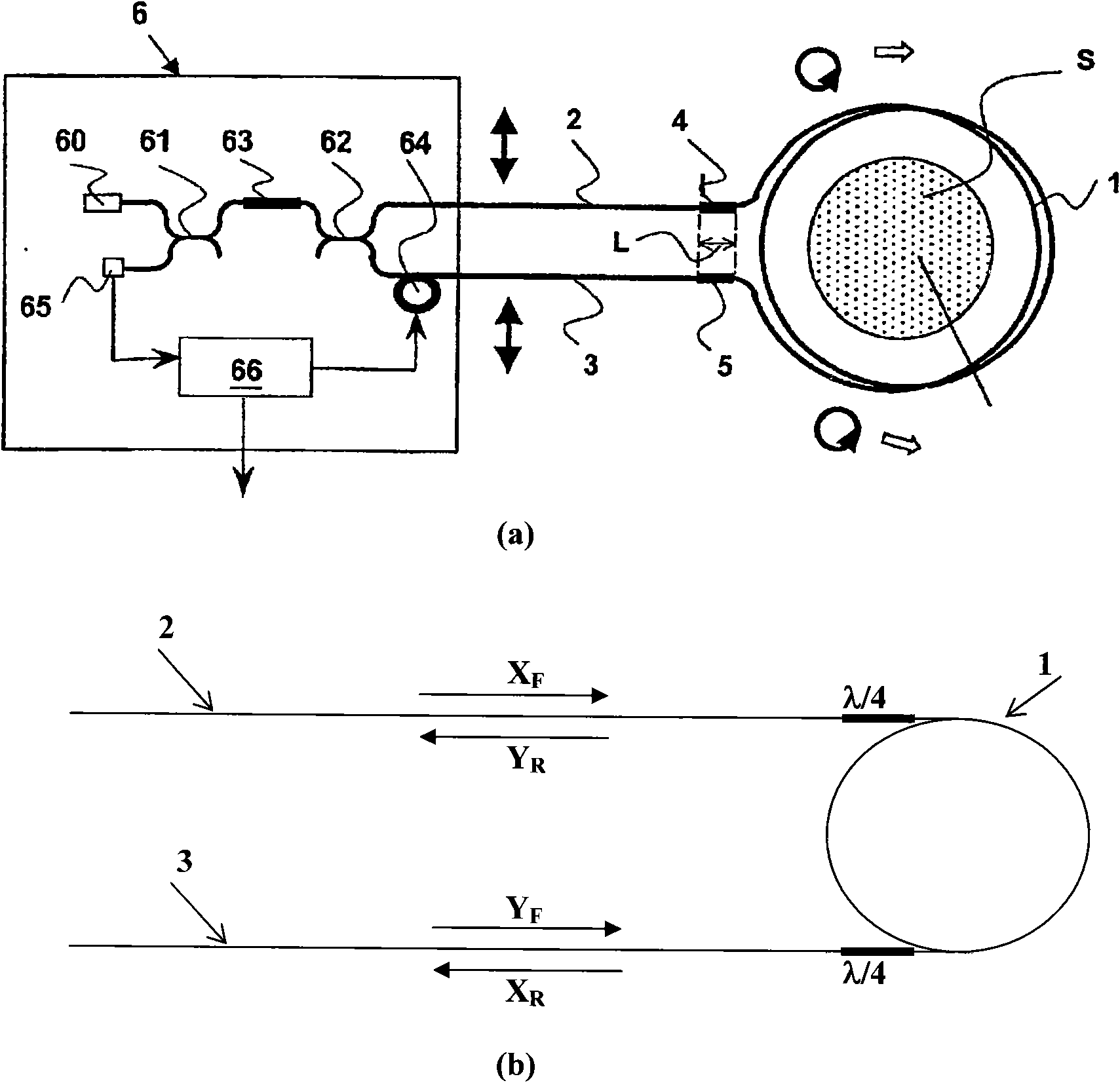

[0080] Image 6 It is the basic embodiment 1 according to the method of the present invention, wherein (a) is a schematic structural view of a fiber wave plate or a fiber polarization state converter (collectively referred to as FWP) of the present invention, and (b) is a fast axis and a slow axis of the FWP relative to the incident light Orientation diagram of X and Y polarization directions. Image 6 In (a), HB1 is the length L 1 A section of HiBi fiber, the thermal expansion coefficient of the fiber is K L1 , the beat length is L B1 , the temperature coefficient of the beat length is K B1 ;HB2 is the length L 2 Another HiBi fiber, the thermal expansion coefficient of the fiber is K L2 , the beat length is L B2 , the temperature coefficient of the beat length is K B2 . The fast axis of HB2 is welded perpendicular to the fast axis of HB1 to form a length L=L 1 +L 2 FWP (the arrangement of HB1 and HB2 is in no particular order).

[0081] A beam of linearly polarized...

Embodiment 2

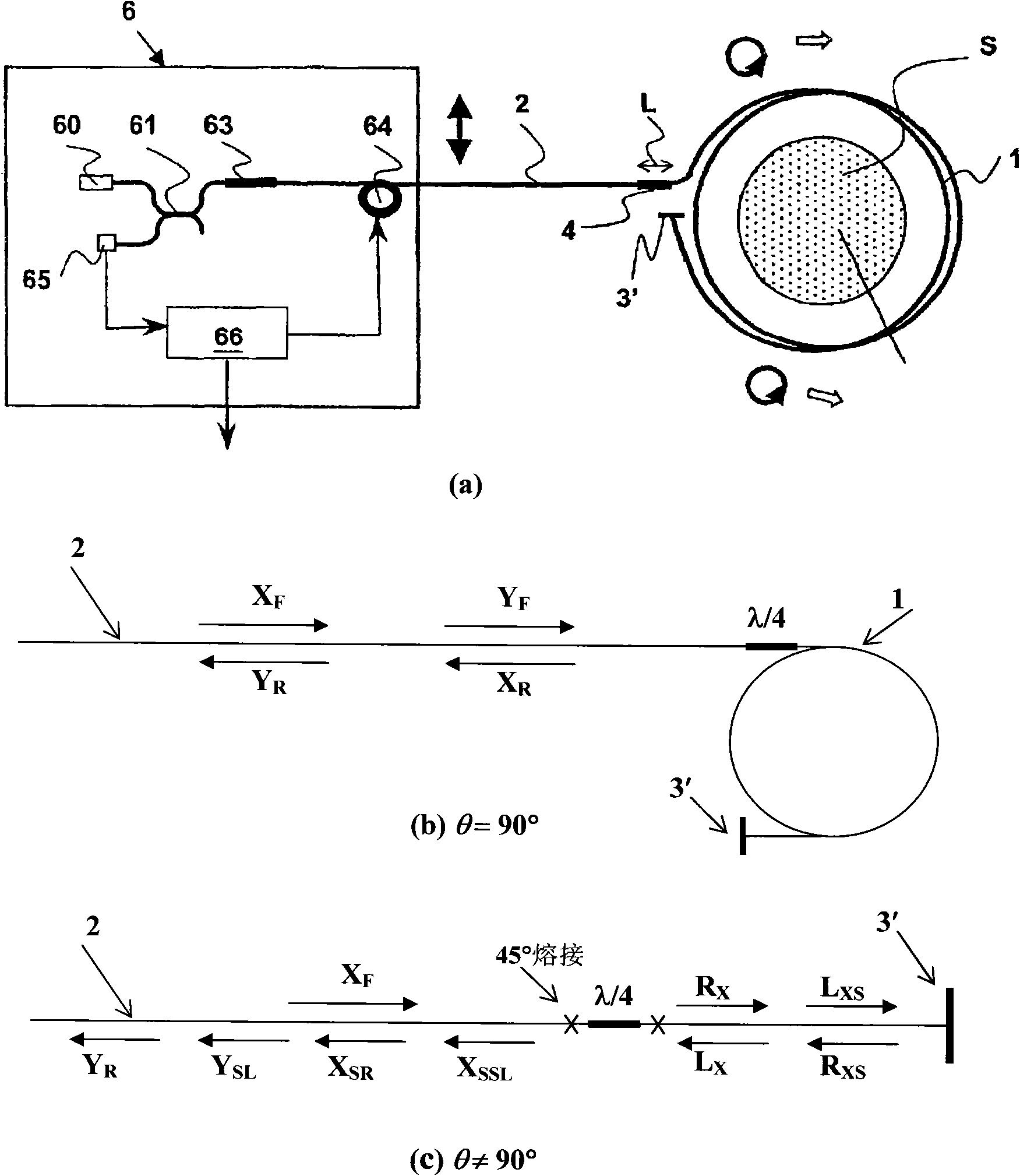

[0133] Figure 7 It is the basic implementation of the temperature complementary FWP according to the method of the present invention, wherein (a) is a structural schematic diagram of this FWP, and (b) is an orientation diagram of the fast axis and the slow axis of the FWP relative to the X and Y polarization directions of the incident light. Figure 7 In (a), HBp is the length L p A section of HiBi fiber, the thermal expansion coefficient of the fiber is K Lp , the beat length is L Bp , the temperature coefficient of the beat length is K Bp ≥0; HBn is the length L n Another HiBi fiber, the thermal expansion coefficient of the fiber is K Ln , the beat length is L Bn , the temperature coefficient of beat length is (-K Bn )ρ +L n The temperature complementary FWP (HBp, HBn in no particular order).

[0134]Imitate the analysis of embodiment 1, at this moment

[0135] θ = φ p + φ n ...

Embodiment 3

[0168] Figure 8 According to the basic embodiment 2 of the present invention, wherein BC1 is a kind of positive crystal (or negative crystal) birefringent optical medium whose thickness is L1 on the direction of light propagation, and BC2 is another kind of positive crystal whose thickness is L2 on the direction of light propagation (or negative crystal) birefringent optical medium, the optical axes of BC1 and BC2 are perpendicular to each other, and both are perpendicular to the direction of light propagation. When L1 and L2 meet the requirements of formula (11), (12), or (11-1), (12-1), or (11-2), (12-2), the delay phase composed of BC1 and BC2 A wave plate of θ has a temperature coefficient of zero.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com