Hydraulic power pulse oil displacement experimental facility and experimental method thereof

A technology of hydraulic pulse and experimental device, which is applied in vibration generating device, earth-moving drilling, and fluid extraction, etc., can solve problems such as total energy loss, affecting the effect of hydraulic pulse equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

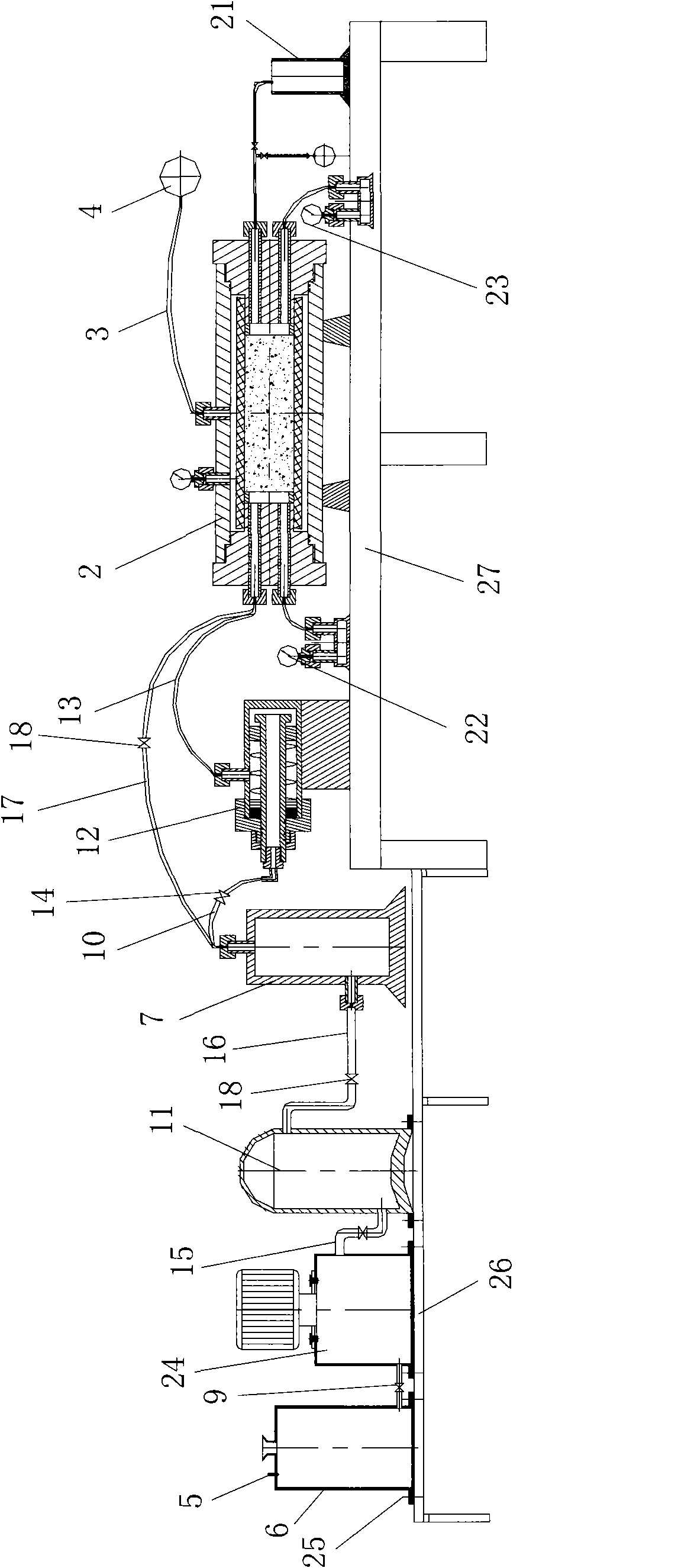

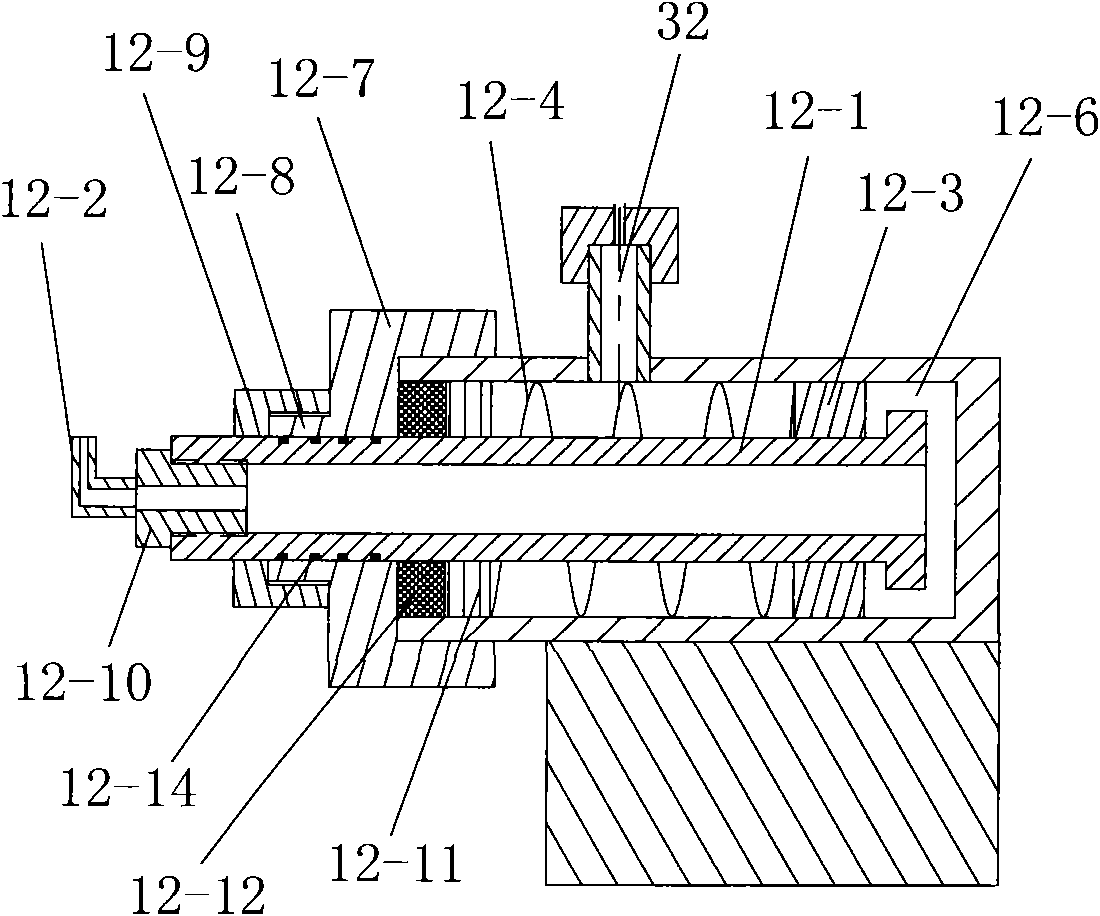

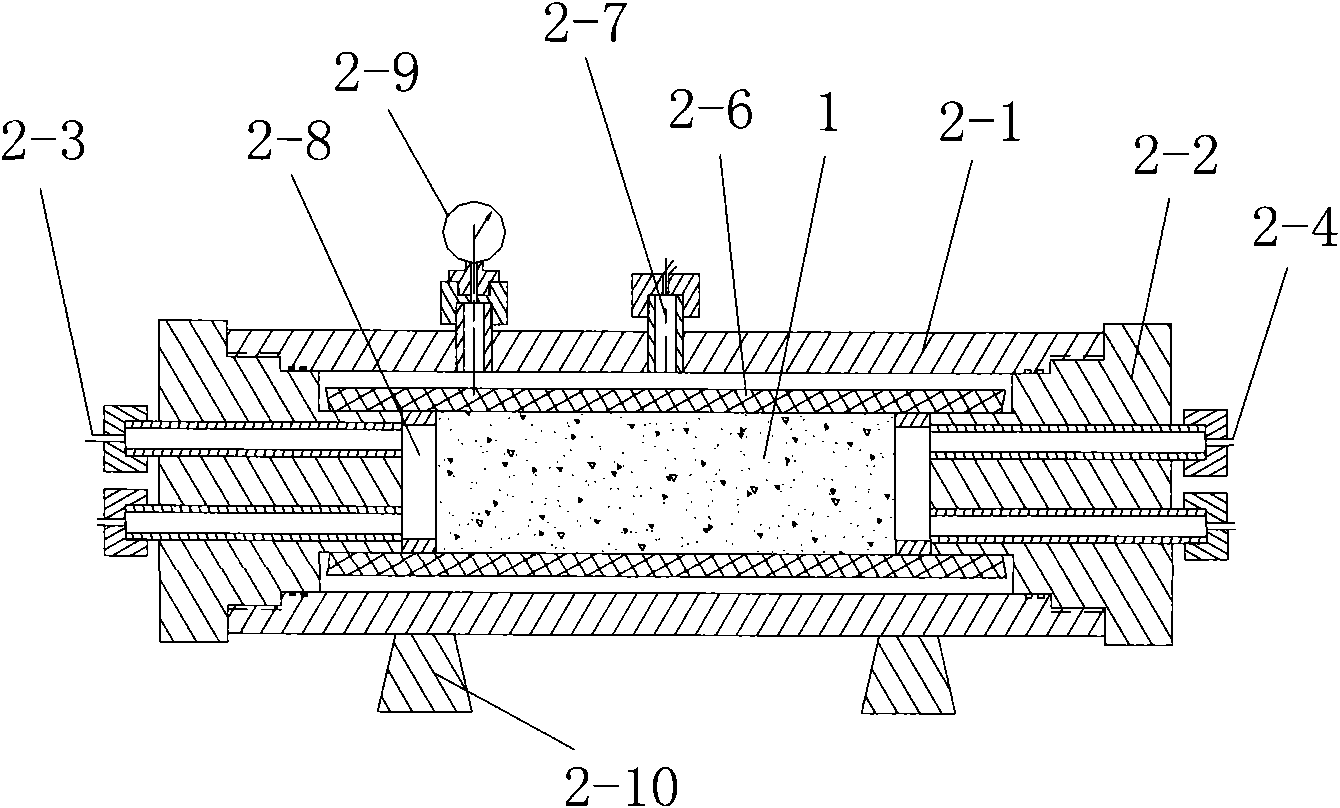

[0075] Such as figure 1 , Figure 4 The hydraulic pulse flooding experimental device shown includes a core holder 2 for holding the tested core 1, a thermostat arranged outside the core holder 2, and a hydraulic pipe 3 connected to the core The annular pressure interface of the holder 2 is connected and the annular pressure supply device 4 and the hydraulic pulse wave generating device 12, which apply annular pressure to the tested rock core 1 clamped inside the core holder 2, pass through the water pipeline respectively. The oil pipeline is connected to the liquid inlet of the core holder 2, and the water storage tank and the oil storage tank of the simulated formation water and the simulated formation oil are respectively installed inside, and the liquid outlet through the external pipeline and the core holder 2 A liquid container with a connected mouth, the liquid container is marked with a scale for measuring the volume of the solution stored in it, the water pipeline and...

Embodiment 2

[0113] Such as Figure 6 As shown, in this embodiment, the difference from Embodiment 1 is that the liquid inlet of the core holder 2 is connected to the chemical reagent preparation tank 29 through the chemical reagent delivery pipeline 28, and the chemical reagent delivery pipeline 28 The chemical reagent delivery control valve 30 and pumping equipment 31 are installed on the top, and the chemical reagent delivery pipeline 28, the chemical reagent preparation tank 29, the chemical reagent delivery control valve 30 and the pumping equipment 31 respectively form a chemical flooding experimental device. The oil test device and the hydraulic pulse flooding test device described in Example 1 jointly constitute a hydraulic pulse-chemical flooding test device. In this embodiment, the hydraulic pulse flooding experimental device used is exactly the same as that in Embodiment 1. Both the chemical reagent delivery control valve 30 and the pumping device 31 are controlled by the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com