Chelating acid of sandstone

An invisible acid and sandstone technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of short penetration distance, equipment corrosion, and poor slow-release effect, so as to achieve small corrosion and avoid secondary precipitation , good slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

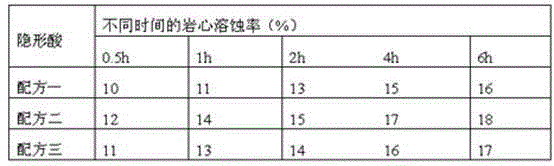

[0011] Example 1: Formula 1: citric acid 5g, ammonium citrate 3g, ammonium chloride 2g, ethylenediaminetetraacetic acid (EDTA) 0.15g, surfactant (hexadecyltrimethylammonium bromide) 0.05g, Add 400mL of water, stir and mix, put 1g of rock core. The acid solution was used to carry out the core dissolution experiment at 80°C, see Table 1.

Embodiment 2

[0012] Example 2: Formula 2: citric acid 5g, ammonium citrate 3g, ammonium fluoride 2g, ethylenediaminetetraacetic acid (EDTA) 0.15g, surfactant (hexadecyltrimethylammonium bromide) 0.05g, Add 400mL of water, stir and mix well, and take 1g of the core mass. The acid solution was used to carry out the core dissolution experiment at 80°C, see Table 1.

Embodiment 3

[0013] Example 3: Formula 3: citric acid 5g, ammonium citrate 3g, ammonium fluoride 1g, ammonium chloride 1g, ethylenediaminetetraacetic acid (EDTA) 0.15g, surfactant (hexadecyltrimethyl bromide Ammonium) 0.05g was added to 400mL water, stirred and mixed, and the mass of the core was 1g. The acid solution was used to carry out the core dissolution experiment at 80°C, see Table 1.

[0014] Table 1 Dissolution of sandstone by invisible acid with different formulations

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com