Method for fast extracting luteolin from Lonicera macranthoides

A technology of honeysuckle and luteolin, applied in the direction of organic chemistry, etc., to achieve the effect of alleviating a large number of demands, simplifying the production process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

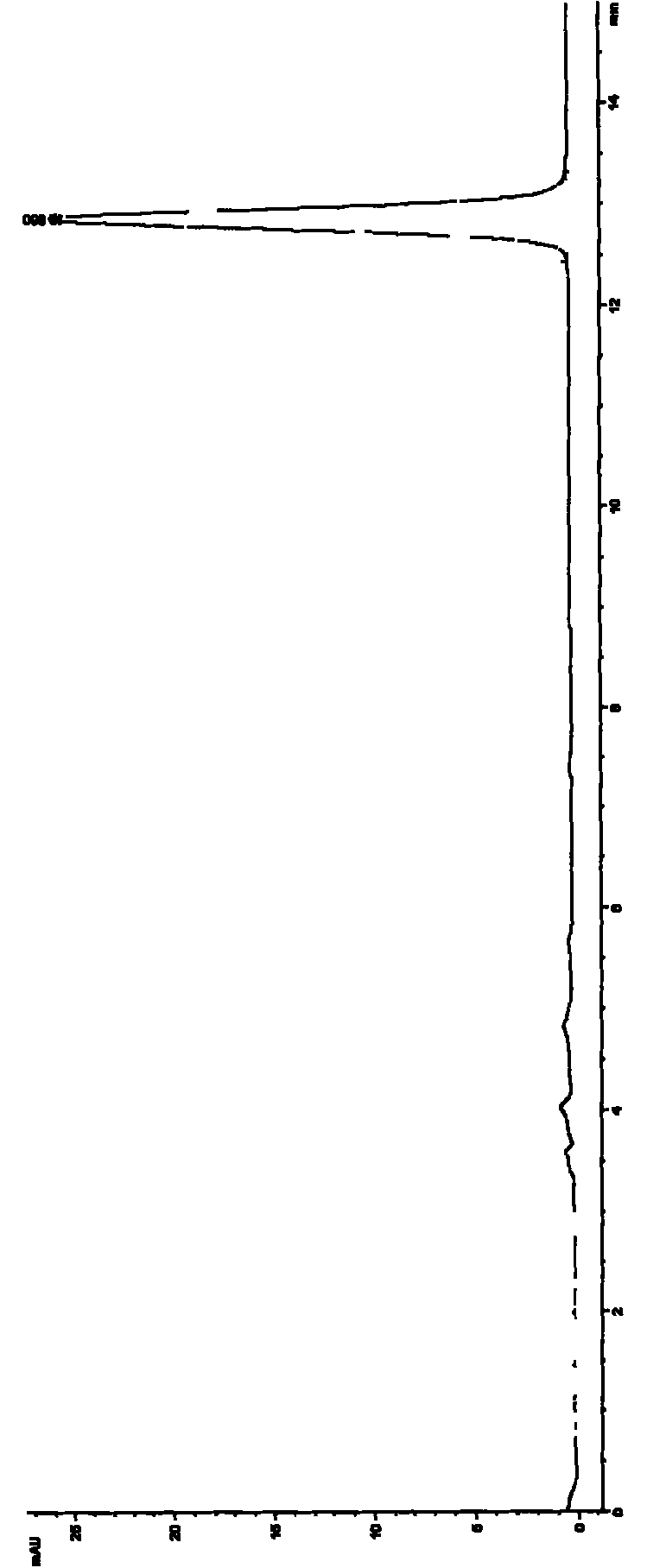

Image

Examples

Embodiment 1

[0036] Crush and dry 100kg of honeysuckle, add 300L of 60% ethanol, heat and reflux at 80°C for 2 hours, filter twice with three layers of gauze, then centrifuge to get the supernatant, concentrate under reduced pressure to 80L (no ethanol smell), and then use the concentrate 150L of ethyl acetate was extracted three times, and the ethyl acetate layer was concentrated to dryness, then heated to dissolve with 80L of 60% ethanol, added 5kg of granular activated carbon for decolorization for 30min, concentrated to dryness, heated to dissolve with 2L of 90% ethanol, and then Heat water and mix until the final ethanol concentration is 40%, and then crystallize at room temperature for 24 hours to obtain a luteolin sample.

[0037] After testing, the Agilent1100 high performance liquid chromatograph, the chromatographic column is Hypersil ODS (150mm×4.6mm, 5μ), the mobile phase is 60% methanol in water; the detection wavelength is 298nm; the flow rate is 1ml / min; the injection volume ...

Embodiment 2

[0039] Crush and dry 500kg of Lonicerae pilosula, add 600L of 60% ethanol, heat and reflux at 80°C for 2 hours, filter twice with three layers of gauze, then centrifuge to get the supernatant, concentrate under reduced pressure to 100L (no ethanol smell), and then use the concentrate Extract three times with 300L ethyl acetate, take the ethyl acetate layer and concentrate to dryness, then heat to dissolve with 150L of 60% ethanol, add 15kg of activated carbon to decolorize for 30min, then concentrate to dryness, heat to dissolve in 6L of 90% ethanol, and then heat water until the final concentration of ethanol was 37%, and crystallized at room temperature for 24 hours to obtain a luteolin sample. Purity detection was carried out according to the method of Example 1, and the purity was 94.27%. The results are shown in Table 1.

Embodiment 3

[0041] Crush and dry 200kg of Lonicerae pilosula, add 200L of 60% ethanol, heat and reflux at 80°C for 2 hours, filter twice with three layers of gauze, then centrifuge to get the supernatant, concentrate under reduced pressure to 50L (no ethanol smell), and then use the concentrate 150L of ethyl acetate was divided into three extractions, the ethyl acetate layer was taken, heated and dissolved in 100L of 60% ethanol, decolorized by adding 8kg of activated carbon for 30min, then concentrated to dryness, heated and dissolved in 3L of 90% ethanol, and then added with hot water until the final ethanol The concentration is 30%, crystallized at room temperature for 24 hours, and a luteolin sample is obtained. Purity testing was carried out according to the method of Example 1, and the purity was 93.86%. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com