Method for preparing triisononyl trimellitate (TINTM)

A technology of trimellitic acid and trimellitic anhydride, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of sewage, serious environmental pollution, and large energy consumption, and reduce waste water Quantity, good product quality, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

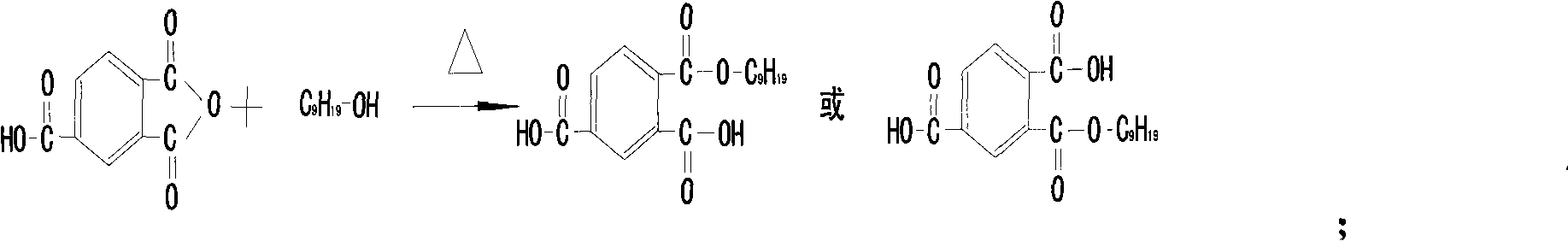

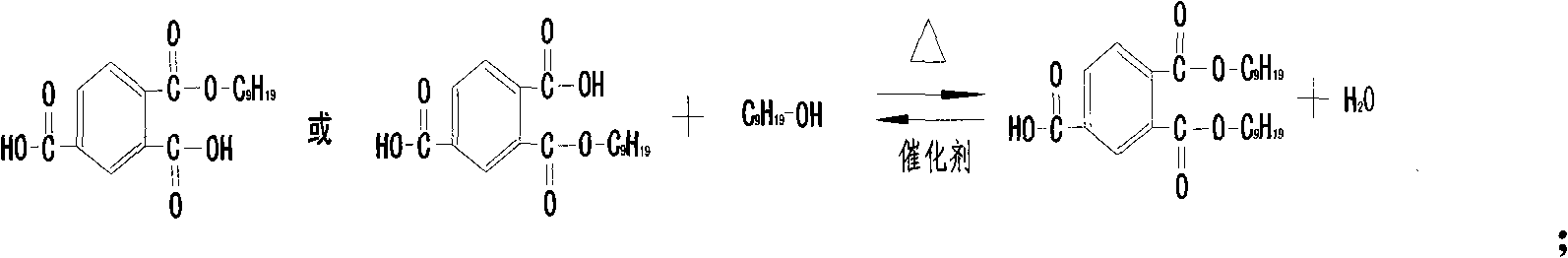

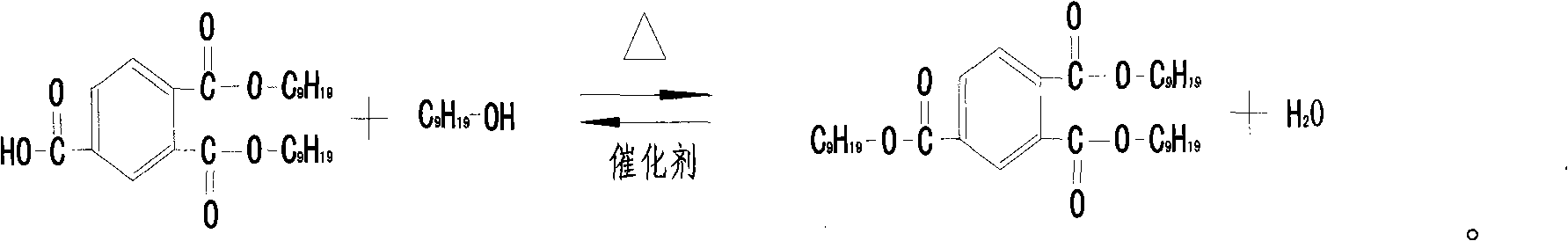

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: at 16m 3 3000Kg of trimellitic anhydride, 7875Kg of isononyl alcohol (feeding ratio of 1:3.5mol), 4.5Kg of activated carbon were put into the stainless steel reaction kettle, and the temperature was stirred, and when the mixture was heated to 185°C, titanic acid with a mass ratio of 1:1 was added Tetrabutyl ester and tetraisopropyl titanate mixed catalyst 3Kg, continue to react at 185°C to 240°C for 4 hours, dealcoholize under negative pressure, add sodium hydroxide solution with a concentration of 10% by mass for neutralization, and make the mixture acidic When it reaches below 0.07mgKOH / g, the esterified water is treated by layering to remove the oil layer, and the treated esterified water is passed into the reactor as an entrainer to dealcoholize and refine. White clay and 20Kg diatomaceous earth were stirred for 30 minutes, and filtered to obtain the finished product.

example example 2

[0030] Example 2: At 16m 3 3000Kg of trimellitic anhydride, 9000Kg of isononyl alcohol (feeding ratio of 1:4.0mol), 4.5Kg of activated carbon were put into the stainless steel reaction kettle, and the mixture was heated to 190°C, and titanic acid was added in a mass ratio of 1:2.5 Tetrabutyl ester and tetraisopropyl titanate mixed catalyst 4Kg, continue to react at 190°C to 240°C for 3.5 hours, dealcoholize under negative pressure, and neutralize with 10% sodium hydroxide solution by mass percentage to make the mixture acidic When it reaches below 0.07mgKOH / g, the esterification water is treated by layering to remove the oil layer, and the treated esterification water is passed into the reactor as an entrainer for dealcoholization and refining, and the temperature is lowered to 150°C, and 10Kg of dried activated clay and 20Kg of diatomaceous earth was stirred for 30 minutes, and filtered to obtain the finished product.

example example 3

[0031] Example 3: At 16m 3 3000Kg of trimellitic anhydride, 10125Kg of isononyl alcohol (feeding ratio is 1:4.5mol), 4.5Kg of activated carbon were put into the stainless steel reaction kettle, and the mixture was heated up to 195°C, and titanic acid with a mass ratio of 1:4 was added. Tetrabutyl ester and tetraisopropyl titanate mixed catalyst 5Kg, continue to react at 195°C to 240°C for 3.0 hours, dealcoholize under negative pressure, and neutralize with 10% sodium hydroxide solution by mass percentage to make the mixture acidic When it reaches below 0.07mgKOH / g, the esterification water is treated by layering to remove the oil layer, and the treated esterification water is passed into the reactor as an entrainer for dealcoholization and refining, and the temperature is lowered to 150°C, and 10Kg of dried activated clay and 20Kg of diatomaceous earth was stirred for 30 minutes, and filtered to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com