Method for preparing isolated supporting point array between vacuum glass substrates by screen printing

A technology of vacuum glass and screen printing, which is applied in glass forming, glass reshaping, glass production, etc. It can solve the problems of loss of vacuum glass effect, complicated manufacturing process, and time-consuming stacking, so as to improve the aesthetics and simplify the process. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

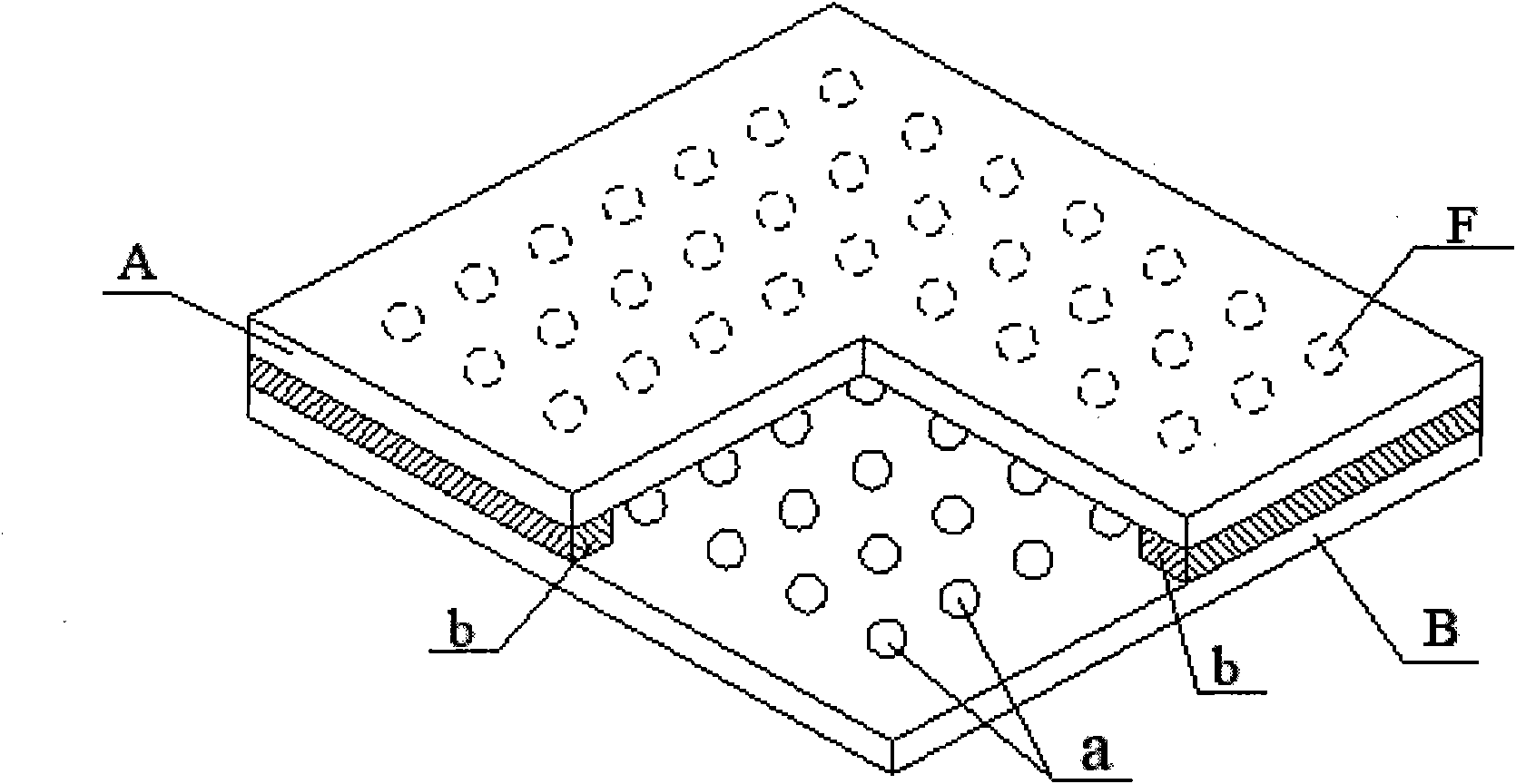

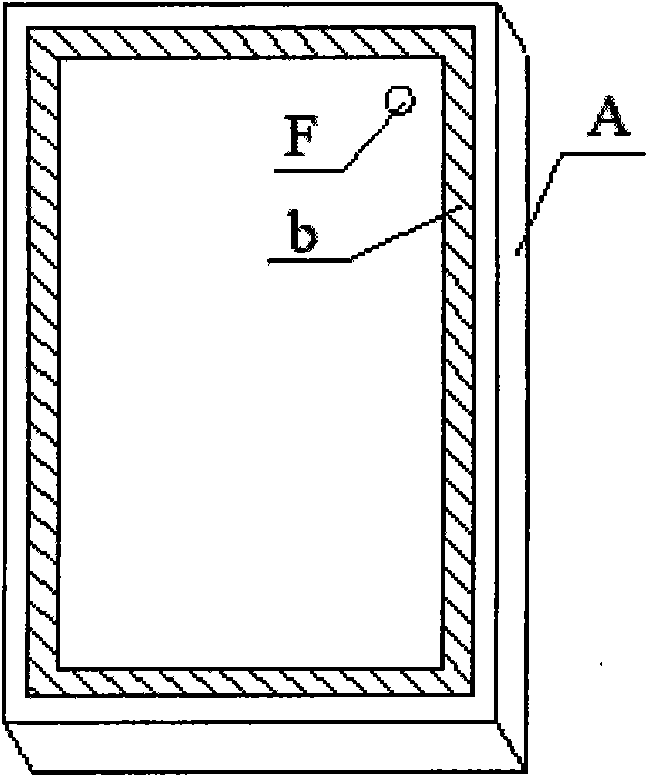

[0031] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

[0032] (2) Use a mechanical drill or a laser drilling machine to make an exhaust hole with a diameter of 2mm on a glass plate. This glass is called the front substrate glass A, and the other glass is called the rear substrate glass B accordingly.

[0033] (3) Make isolation support points on the rear glass substrate by screen printing method. A rheological slurry suitable for screen printing is prepared by using amorphous low-melting glass powder M with a thermal expansion coefficient slightly smaller than that of the glass panel and an organic solution. Then use the screen printing method to print a lattice of cylindrical dots with a diameter of about 0.5mm and a thickness of about 25-35μm on the rear sub...

Embodiment 2

[0040] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

[0041] (2) Use a mechanical drill or a laser drilling machine to make a vent hole with a diameter of 1mm on a glass plate. This piece of glass is called the front substrate glass. Correspondingly, the other piece of glass is called the rear substrate glass.

[0042] (3) Make isolation support points on the rear substrate glass by screen printing. Use amorphous low-melting glass powder M with a thermal expansion coefficient slightly smaller than that of the glass panel and an organic solution to prepare a rheological slurry suitable for screen printing. Then use the screen printing method to print a dot matrix formed by wet film cylindrical dots with a diameter of about 0.5mm and a thickness of about 230-24...

Embodiment 3

[0049] (1) Cut, edge and clean the original glass plate according to the required size. The original glass plate can be ordinary float glass, tempered glass, various coated glass, self-cleaning glass, low-emissivity glass, high visible light transmittance glass and so on.

[0050] (2) Use a mechanical drill or a laser drilling machine to make a vent hole with a diameter of 3mm on a glass plate. This glass is called the front substrate glass A, and the other glass is called the rear substrate glass B accordingly.

[0051] (3) Make isolation support points on the rear substrate glass by screen printing. Use amorphous low-melting glass powder M with a thermal expansion coefficient slightly smaller than that of the glass panel and an organic solution to prepare a rheological slurry suitable for screen printing. Then use the screen printing method to print a dot matrix formed by wet film cylindrical dots with a diameter of about 0.5mm and a thickness of about 135-145μm on the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com