Suspension uni-directional/bi-directional steam catapult

A catapult and steam technology, applied in the direction of launch/drag transmission, etc., can solve the problems of slow take-off of fighters, frequent replacement of U-shaped sealing strips, high maintenance costs, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

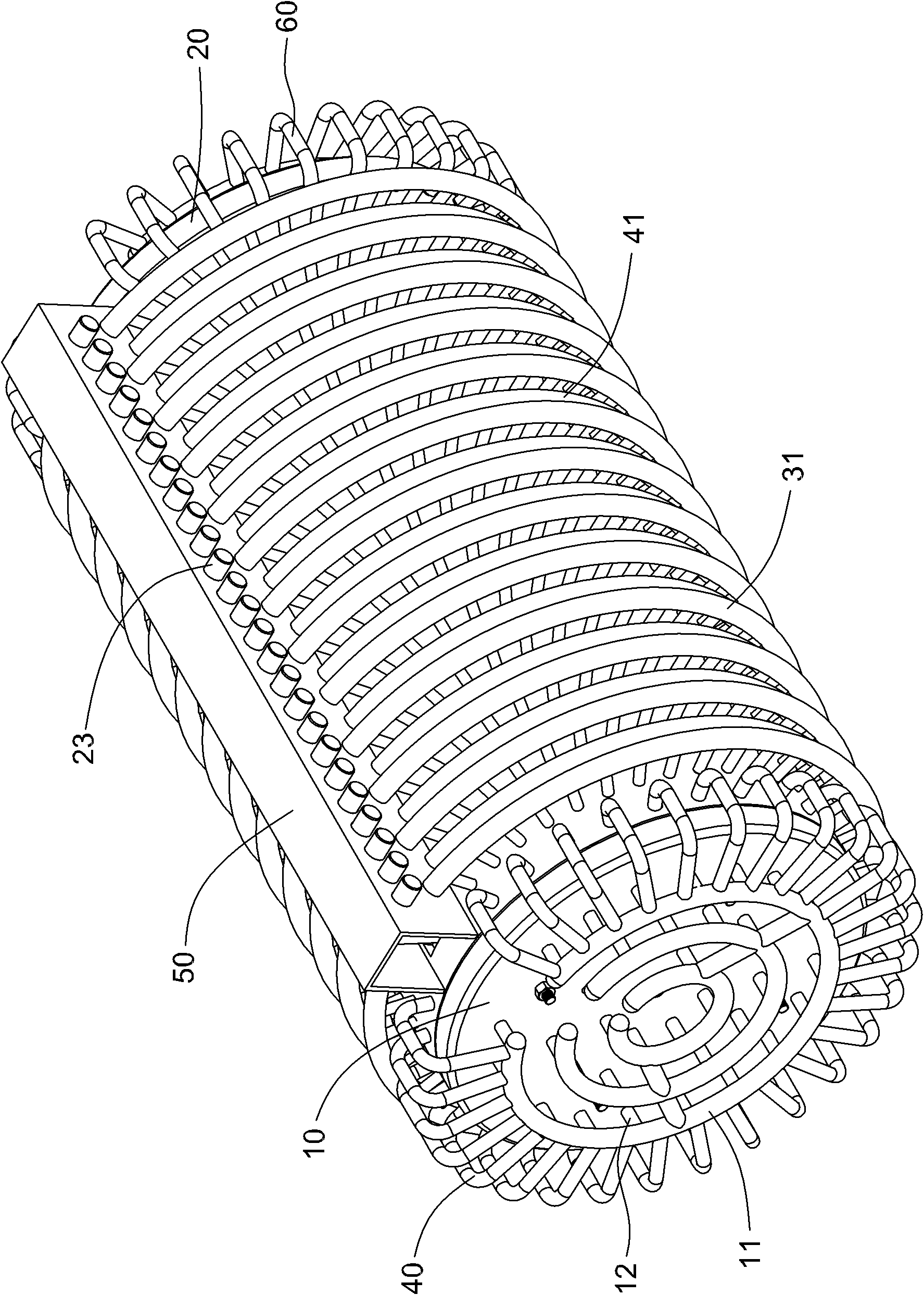

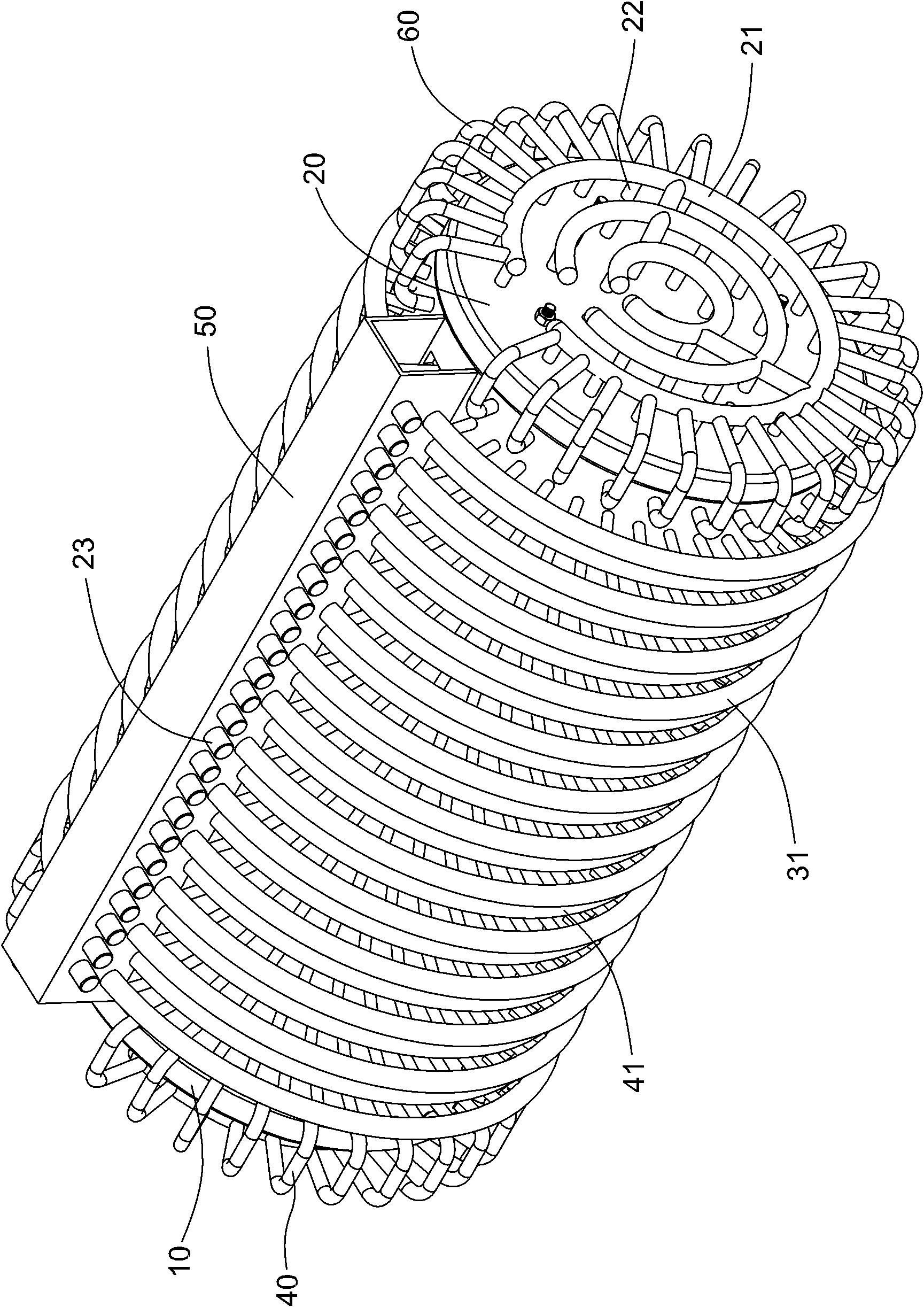

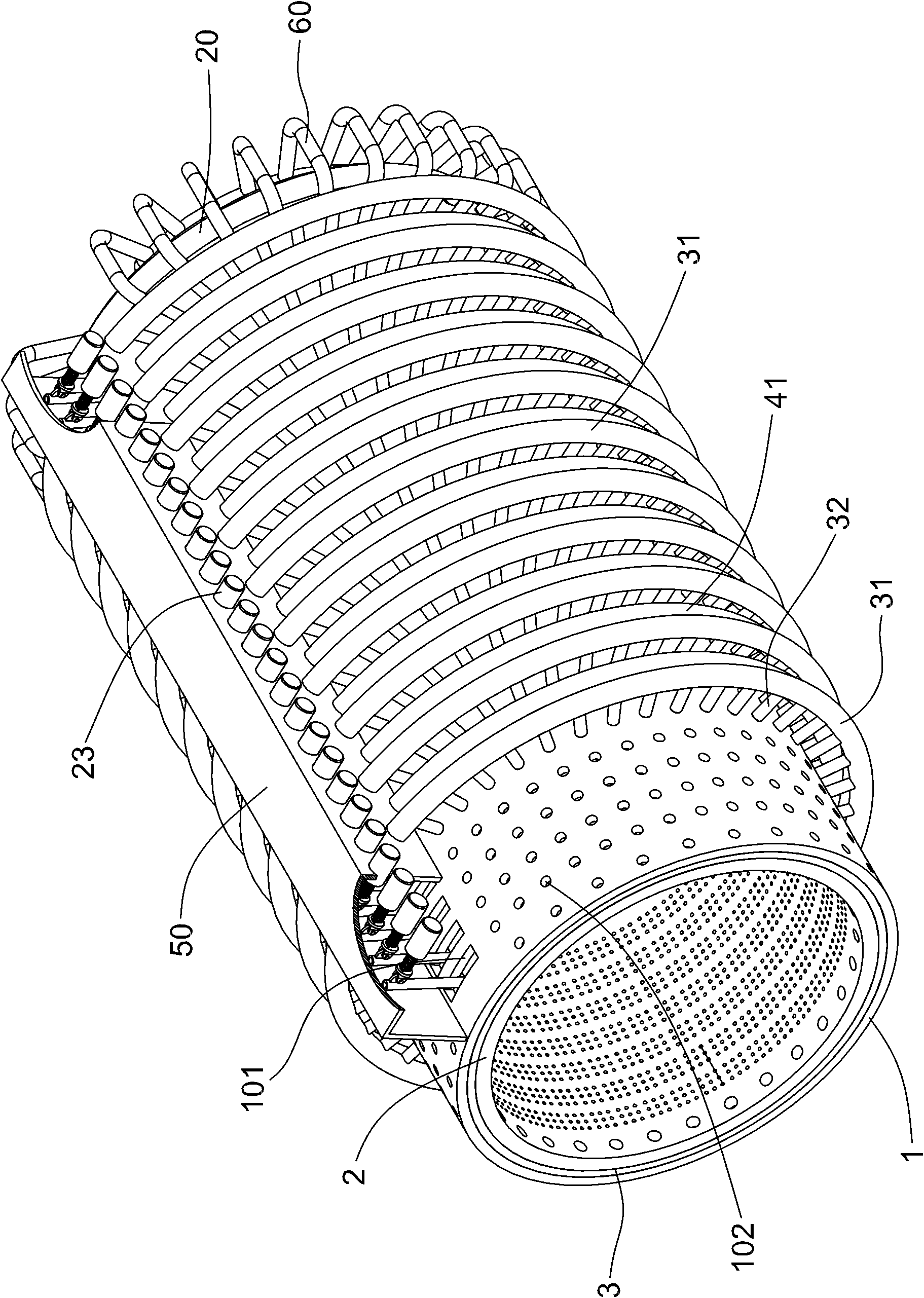

[0030] Label in the figure

[0031] 1 outer cylinder 101 outer long slot 102 steam port 103 steam distribution cavity

[0032] 2 Inner barrel 202 micro steam hole 203 big steam hole 204 big steam hole

[0033] 3 left end ring 301 large steam hole 4 right end ring 401 large steam hole

[0034] 5 control ring 501 screw hole 502 micro steam hole

[0035] 8 left tunnel pipe 9 right tunnel pipe

[0036] 10 Left cylinder head 11 Left steam pipe 12 Short pipe

[0037] 13 Suspension bar 14 Control rod 141 Ear plate 142 Bolt hole

[0038] 15 signal axis

[0039] 16 Left buffer 17 Right buffer 18 Sealed bearing seat 19 Sealed bearing seat

[0040] 20 Right cylinder head 21 Right steam pipe 22 Short pipe

[0041] 23 solenoid valve 24 valve stem 25 return spring 26 ear seat

[0042] 27 pin shaft 28 left steel cable 29 right steel cable

[0043] 30 Piston 31 Steam pipe

[0044] 32 short tube 33 mandrel 34 spacer 35 permanent magnetic ring

[0045] 36 insulating tube 37 slider 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com