Method for drawing steel wire

A wire drawing technology for steel wire and water tank is applied in the field of wire drawing, which can solve the problems of complicated process and increase production cost, and achieve the effect of simplifying the process and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the drawings and embodiments.

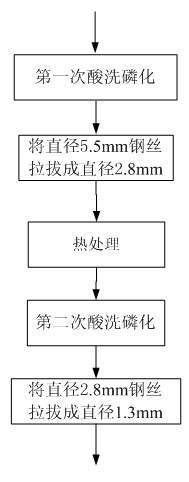

[0013] The figure is a schematic diagram of the steel wire drawing method of the present invention.

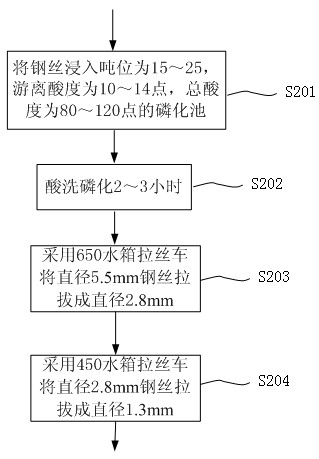

[0014] See figure 2 The steel wire drawing method provided by the present invention includes the following steps in sequence:

[0015] Step S201: Immerse the steel wire to be drawn into a phosphating pool with a tonnage of 15-25, a free acidity of 10-14, and a total acidity of 80-120, and then proceed to step S202;

[0016] Step S202: pickling and phosphating for 2 to 3 hours to form a phosphor layer with a thickness and bonding force that conform to the drawing, go to step S203;

[0017] Step S203: Then, the steel wire with a diameter of 5.5mm is stretched to 2.8mm at a time using a water tank drawing car with a drum diameter of 650mm, and then step S204 is entered;

[0018] Step S204: Finally, a water tank drawing car with a drum diameter of 450 mm is used to stretch the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com