Single-cell assembly and test tool of fuel cell

A fuel cell and test tooling technology, applied in fuel cells, solid electrolyte fuel cells, circuits, etc., can solve the problems of difficult miniaturization design, large volume and weight, and uneven force on the battery, so as to achieve large-scale use and system The effect of simple structure and perfect system function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

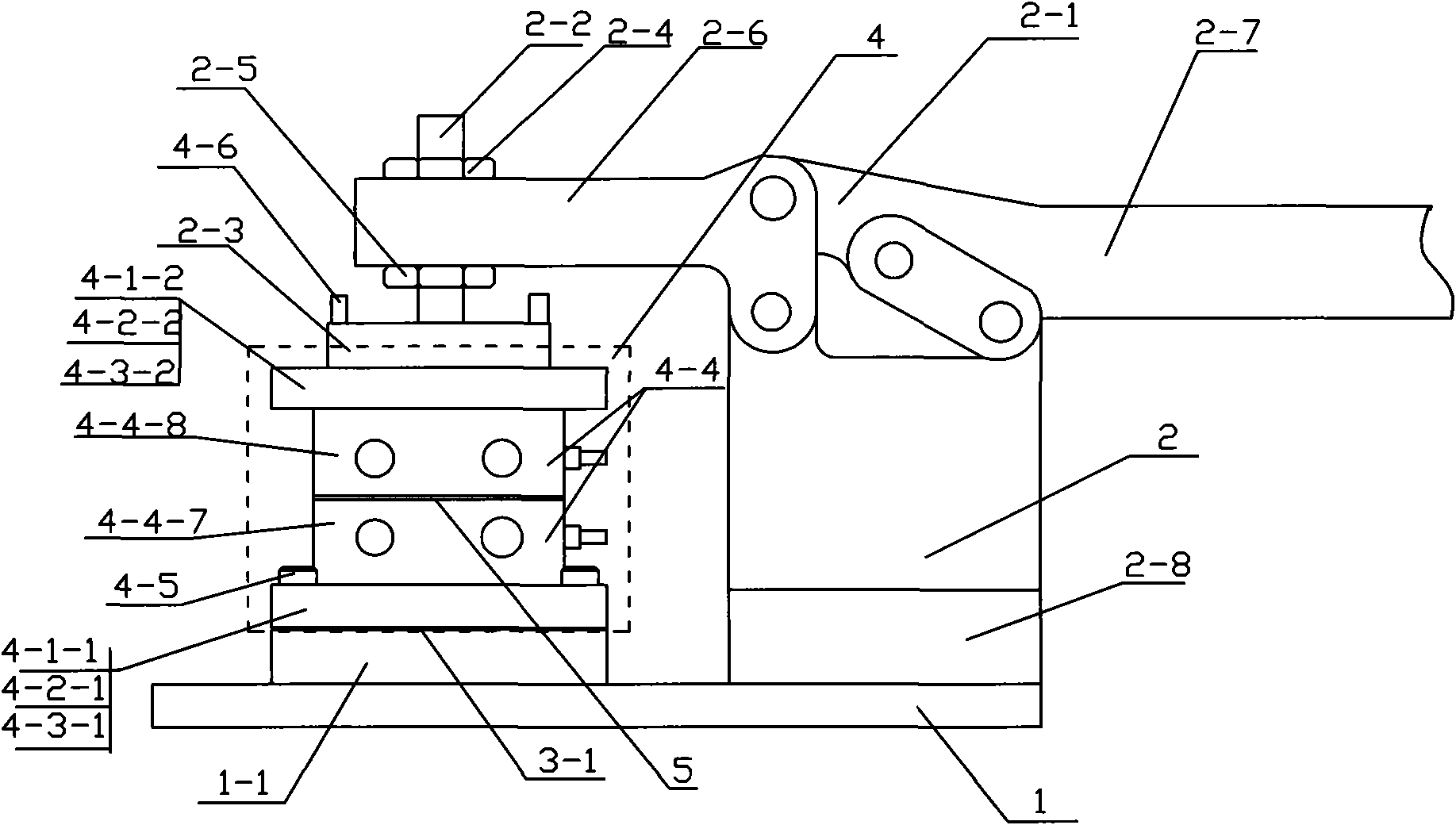

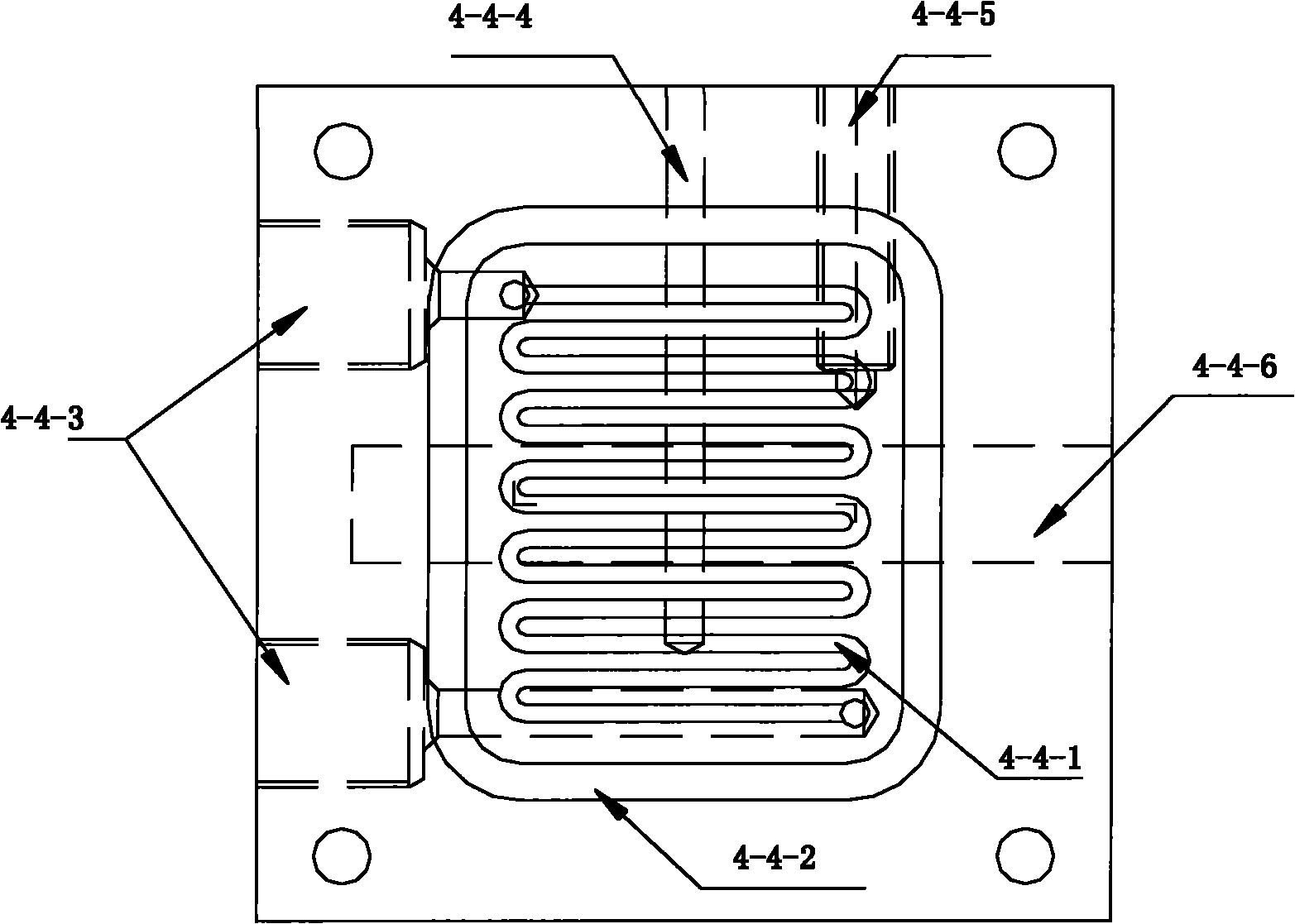

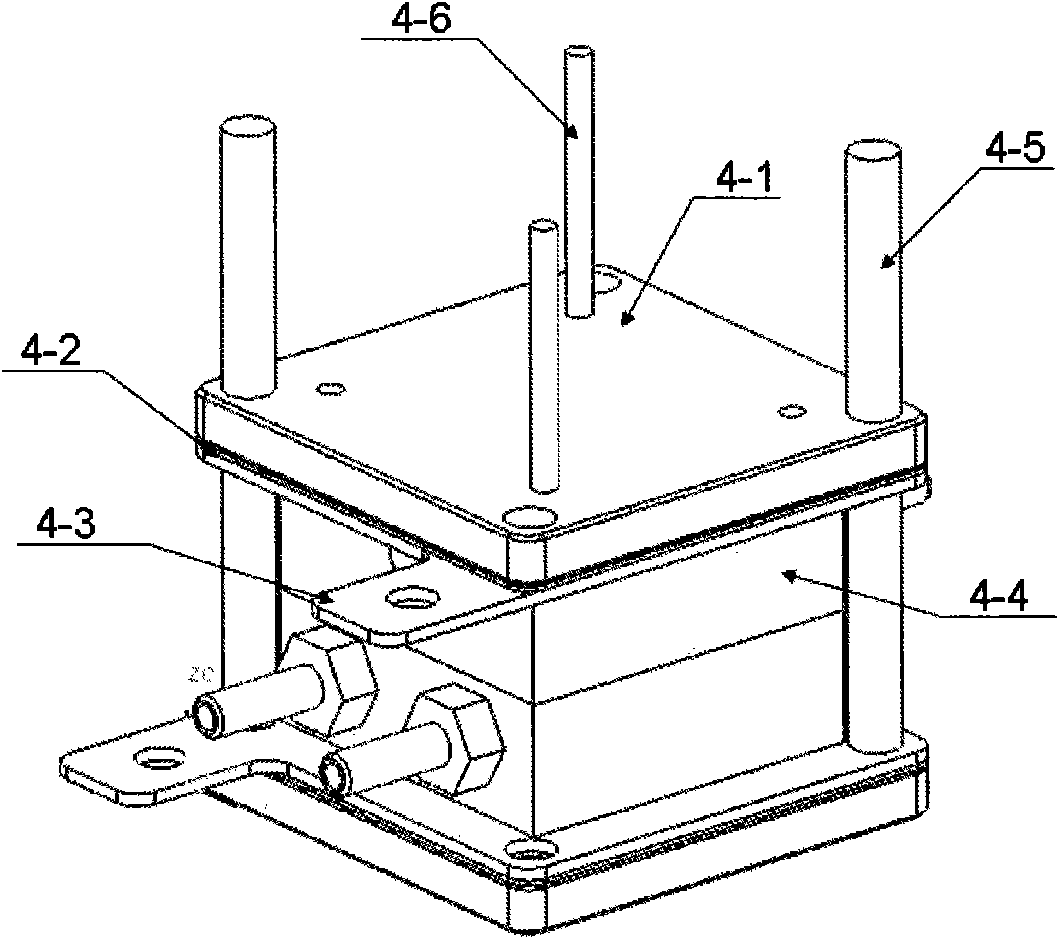

[0022] As shown in the attached figure, a fuel cell single cell that can be installed and disassembled quickly and conveniently under the condition of ensuring uniform stress on the single cell is assembled on the test tool, including a bottom plate 1, an adjustable pressure applying device 2, and a pressure measuring device 3. Single battery test part 4. The adjustable pressure applying device is fixed on the bottom plate 1, and the position is located on the right side of the battery test part, consisting of a pressure applying screw 2-2, a screw fixing device 2-1, a pressure distribution device 2-3, a fixing nut 2-4, a pressure The adjustment nut 2-5 is composed; the pressure measurement part is composed of a pressure sensor 3-1 and a digital display pressure gauge 3-2, the pressure sensor 3-1 is fixed on the bottom plate single battery test fixed platform 1-1, the lower part of the single battery test part, It is connected with the digital display pressure gauge 3-2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com