Method for controllably loading metal platinum on surface of multi-wall carbon nanotube through in-situ synthesis

A technology of multi-walled carbon nanotubes and metal loading, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high price, low utilization rate, catalyst poisoning, etc., and achieve improved catalytic performance, increased utilization rate, and scalable size control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 10.0 mg of MWNTs to 20.0 mL of triethylene glycol, ultrasonically treat it (power 170 W) for 5 min, and then add 30.0 mg of Pt(acac) 2 Add to this suspension, and continue to sonicate for 15 min to make it completely dispersed.

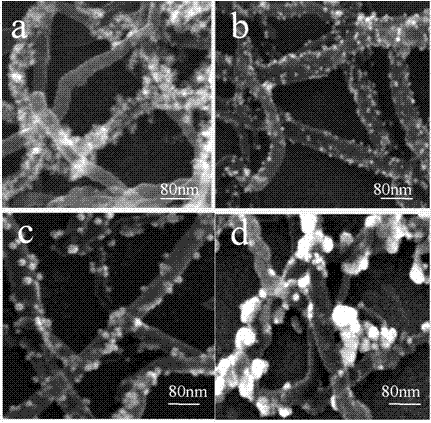

[0027] (2) Under the conditions of magnetic stirring at a rotational speed of 350 r / min and nitrogen deoxygenation for 45 min, the temperature was sequentially raised to (a) 220 °C, (b) 245 °C, (c) at a rate of 2.5 °C / min 262 °C, (d) 296 °C, reflux for 30 min at the corresponding reaction temperature, and cool to room temperature.

[0028] (3) Add 20.0 mL of absolute ethanol to the reactant to dilute the solution, then centrifuge and wash the product 6 times with absolute ethanol (9000 r / min), each centrifugation time is 6 min. Dry in vacuum at 60 °C for 8 h. The Pt / MWNTs nanocomposite material with Pt NPs of different shapes and particle sizes supported on the surface of MWNTs can be obtained.

[0029] ...

Embodiment 2

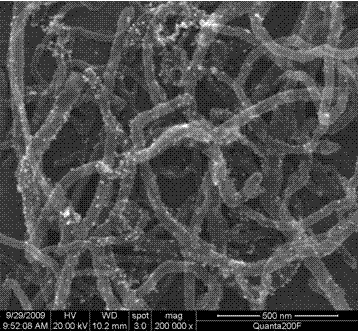

[0031] (1) Add 10.0 mg of MWNTs to 20.0 mL of triethylene glycol, ultrasonically treat it with an ultrasonic instrument (power 150 W) for 5 min, and then add 10.0 mg of Pt(acac) 2 Add to this suspension, and continue to sonicate for 15 min to make it completely dispersed.

[0032] (2) Under the conditions of magnetic stirring at a rotation speed of 350 r / min and nitrogen deoxygenation for 45 min, the temperature was raised to 245 °C at a rate of 2.5 °C / min, refluxed at this reaction temperature for 30 min, and cooled to room temperature.

[0033] (3) Add 20.0 mL of absolute ethanol to the reactant to dilute the solution, and then centrifuge and wash the product 6 times with absolute ethanol (10000 r / min), each centrifugation time is 4 min. Dry in vacuum at 70 °C for 9 h. That is, Pt / MWNTs nanocomposites with Pt NPs loading of 21 wt% were obtained.

[0034] The scanning electron micrographs of the prepared Pt / MWNTs nanocomposites are shown in figur...

Embodiment 3

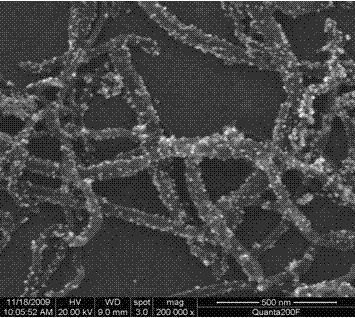

[0036] (1) Add 10.0 mg of MWNTs to 20.0 mL of triethylene glycol, ultrasonically treat it (power 170 W) for 5 min, and then add 30.0 mg of Pt(acac) 2 Add to this suspension, and continue to sonicate for 15 min to make it completely dispersed.

[0037] (2) Under the conditions of magnetic stirring at a rotation speed of 350 r / min and nitrogen deoxygenation for 45 min, the temperature was raised to 245 °C at a rate of 2.5 °C / min, refluxed at this reaction temperature for 30 min, and cooled to room temperature.

[0038] (3) Add 20.0 mL of absolute ethanol to the reactant to dilute the solution, then centrifuge and wash the product 6 times with absolute ethanol (9000 r / min), each centrifugation time is 6 min. Dry in vacuum at 65 °C for 10 h. That is, Pt / MWNTs nanocomposites with Pt NPs loading of 50 wt% were obtained.

[0039] The scanning electron micrographs of the prepared Pt / MWNTs nanocomposites are shown in image 3 , it can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com