Cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material

A technology of surface migration and polyvinyl chloride, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of hardening of PVC soft materials, performance degradation, poor compatibility, etc., and achieve excellent resistance to low temperature embrittlement , Excellent impact resistance at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

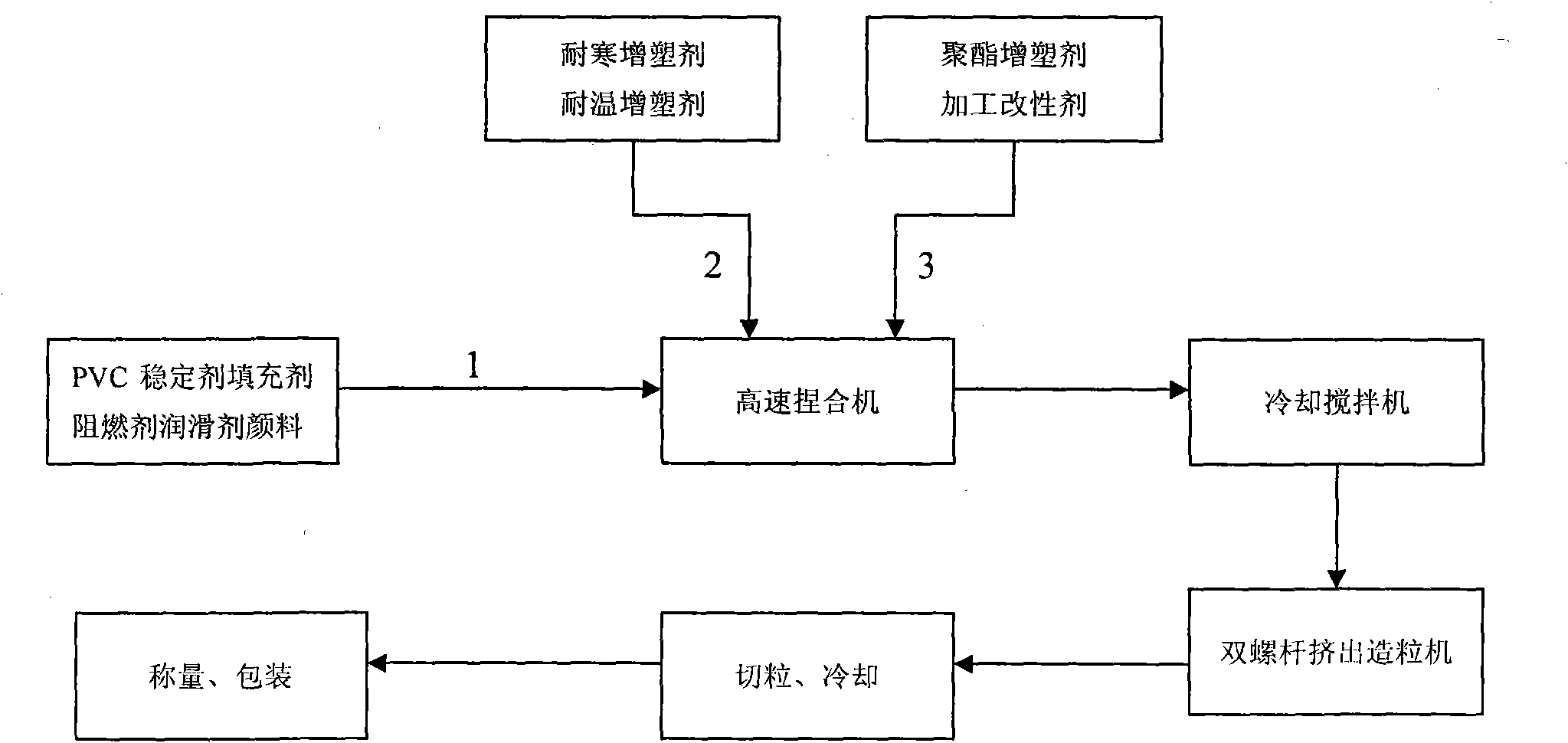

Method used

Image

Examples

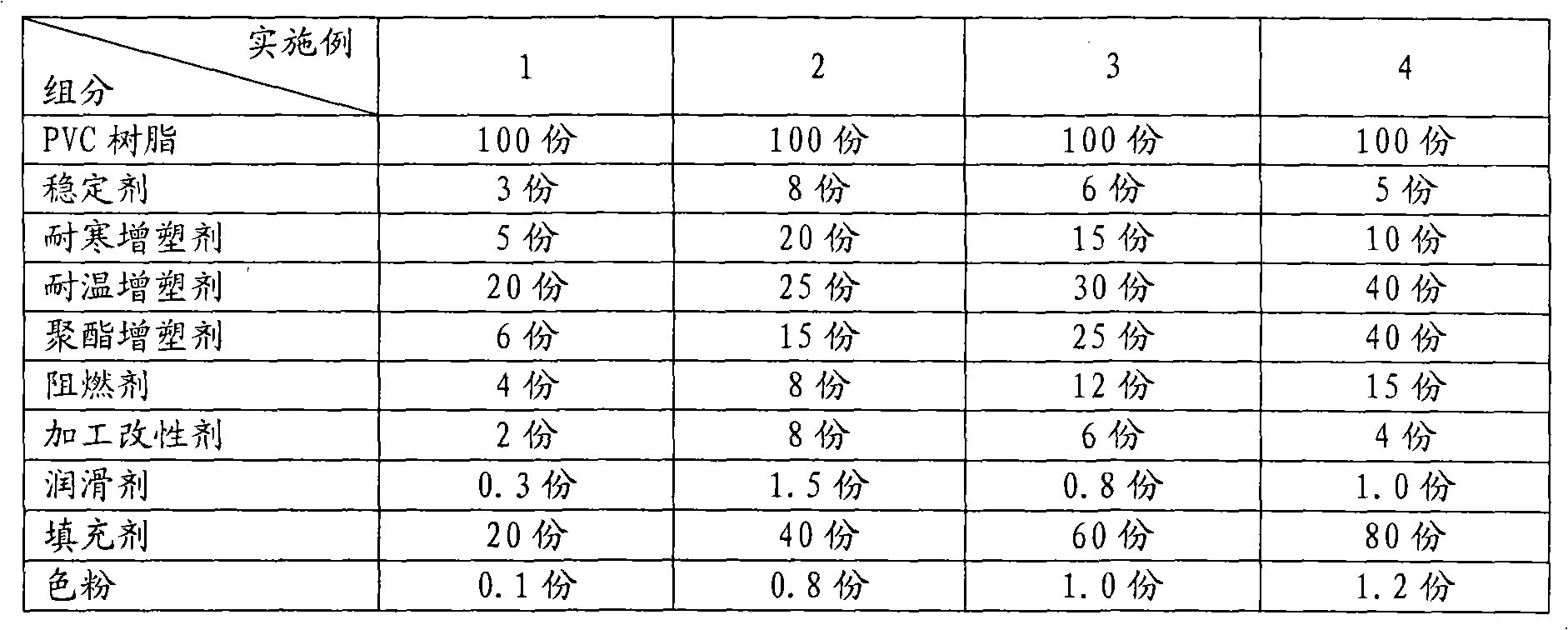

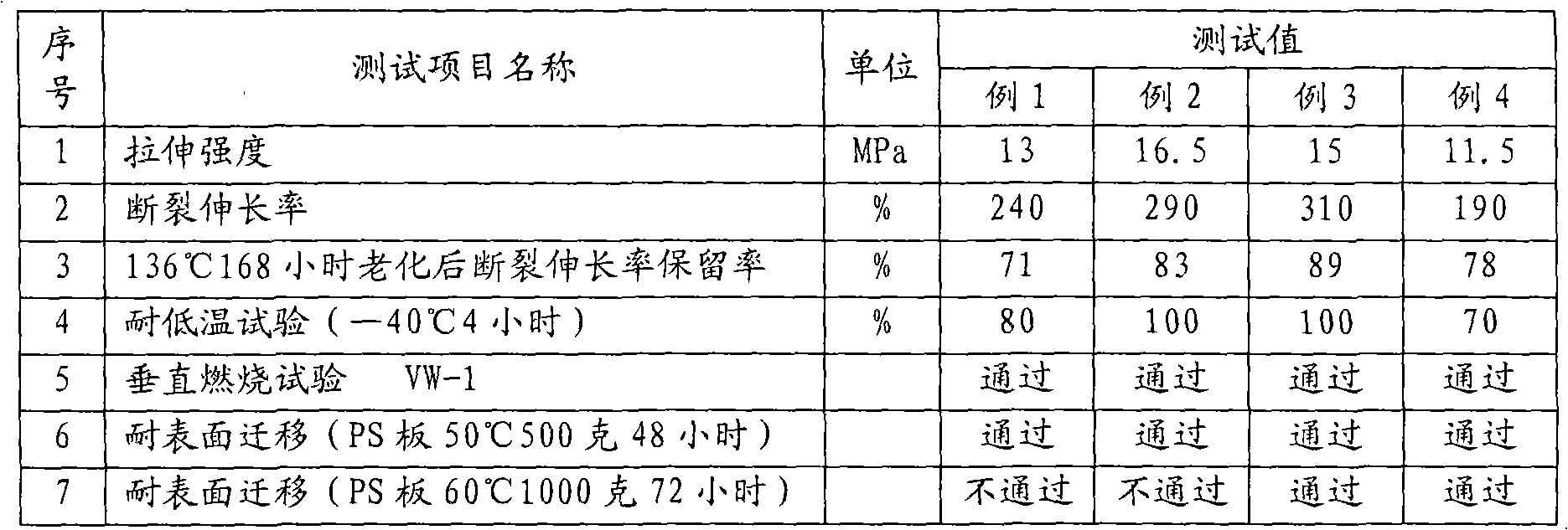

Embodiment 1

[0025] The PVC resin described in embodiment 1 is the resin that molecular weight is 1000; Described stabilizer is calcium-zinc composite stabilizer; Described cold-resistant plasticizer is two (2-ethylhexyl) adipates; Described temperature-resistant plasticizer is made up of the composition of following parts by weight: 17 parts of trioctyl trimellitate (TOTM), 3 parts of epoxy soybean oils; Described polyester polymer plasticizer is polyadipic acid 1,2-propylene glycol ester; the flame retardant is composed of the following parts by weight: 2.5 parts of antimony trioxide, 1.5 parts of magnesium hydroxide; the modifier is chlorinated polyethylene (CPE); the Described filler agent is made up of the composition of following parts by weight: 10 parts of heavy calcium carbonate, 10 parts of nano active calcium carbonates; Described lubricant is made up of the composition of following parts by weight: calcium stearate 0.2 part, oxidized polyethylene 0.1 part of wax; the pigment is...

Embodiment 2

[0026]The PVC resin described in Example 2 is a resin with a molecular weight of 1300; the stabilizer is composed of the following components by weight: 4 parts of rare earth composite stabilizers, 4 parts of calcium-zinc composite stabilizers; The plasticizer is bis(2-ethylhexyl) sebacate; the temperature-resistant plasticizer is made up of the following parts by weight: 22 parts of trioctyl trimellitate (TOTM), 3 parts of epoxidized soybean oil part; the polyester polymer plasticizer is poly-1,2-trimethylene adipate; the flame retardant is composed of the following parts by weight: 4 parts of antimony trioxide, 4 parts of aluminum hydroxide The modifier is chlorinated polyethylene (CPE); the filler is made up of the following parts by weight: 20 parts of heavy calcium carbonate, 15 parts of nano-active calcium carbonate, and 5 parts of calcined kaolin; The lubricant consists of the following components by weight: 0.8 part of calcium stearate, 0.7 part of oxidized polyethylen...

Embodiment 3

[0027] The PVC resin described in embodiment 3 is the resin that molecular weight is 1000; Described stabilizer is calcium-zinc composite stabilizer; Described cold-resistant plasticizer is two (2-ethylhexyl) adipates; Described temperature-resistant plasticizer is made up of the composition of following parts by weight: trioctyl trimellitate (TOTM) 26 parts, epoxy soybean oil 4 parts; Described polyester polymer plasticizer is polyadipic acid 1,2-propylene glycol ester; the flame retardant is composed of the following parts by weight: 5 parts of antimony trioxide, 7 parts of magnesium hydroxide; the modifier is powdered nitrile rubber; the filler The agent is composed of the following components by weight: 25 parts of heavy calcium carbonate, 25 parts of nano-active calcium carbonate, and 10 parts of calcined kaolin; the lubricant is composed of the following components by weight: 0.4 parts of calcium stearate, oxidized poly 0.4 part of ethylene wax; Described pigment is coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com