Casting polypropylene (CPP) membrane for paper packaging and preparation method thereof

A technology for film and paper products, applied in the field of CPP film for paper product packaging and its preparation, can solve the problems of poor heat-sealing and printing adaptability, reduced heat-sealing performance, too hard texture, etc., and achieve good double-sided heat-sealing performance , high smoothness on both sides and satisfactory mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides the preparation method of the above-mentioned CPP film for paper product packaging, comprising:

[0040] a) co-extruding the outer layer resin, the middle layer resin and the inner layer resin at 210°C to 250°C to obtain a hot-melt film including the outer layer, the middle layer and the inner layer in sequence;

[0041] b), casting and cooling the hot-melt film;

[0042] c), corona treatment is carried out on the outer layer of the film after casting cooling and setting, and the CPP film used for paper product packaging is obtained;

[0043] Wherein, the outer layer resin includes 98wt% to 99.5wt% terpolymerized polypropylene and 0.5wt% to 2wt% slip agent; the middle layer resin is homopolypropylene; the inner layer resin includes 98wt% to 99.5wt% binary copolymerized polypropylene and 0.5wt%-2wt% slip agent.

[0044] In the present invention, the outer layer resin, the middle layer resin and the inner layer resin are preferably re...

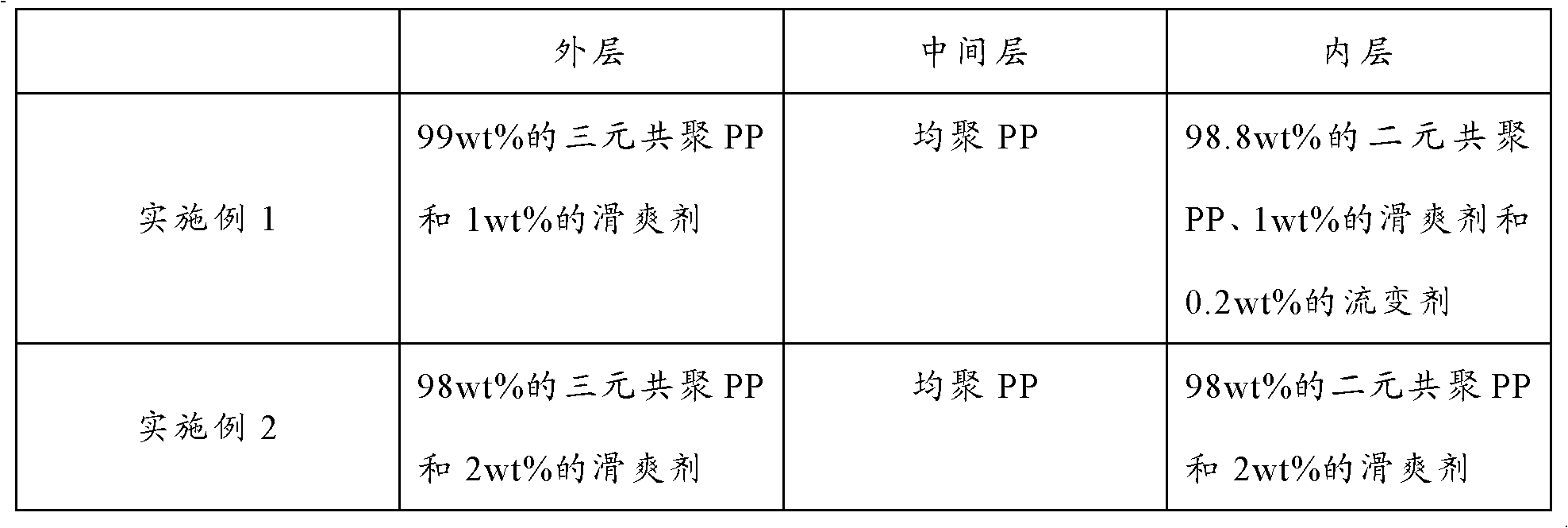

Embodiment 1

[0049] Add the outer layer resin raw material, the middle layer resin raw material and the inner layer resin raw material respectively into the three barrels of the co-extrusion machine, and the formulas of each resin raw material are listed in Table 1.

[0050] The raw materials in the three barrels are co-extruded and then enter the casting station to cool and shape. Temperature: 245° C.; the surface temperature of the casting roll is set at 30° C. in the casting process. Air knife up and down position: 90%; air knife speed: 50%; vacuum box wind speed: 35%; air knife horizontal position: 18%; air knife pressure: 5.2mbar; vacuum box pressure: 1.2mbar.

[0051] Carry out corona treatment on the outer surface of the cast film after corona treatment, set the corona treatment power to 8.5KW, and the corona roller pressure to 3bar. After corona treatment, a paper packaging CPP film is obtained. The thickness ratio of the layer, middle layer and inner layer is 1:8:1.

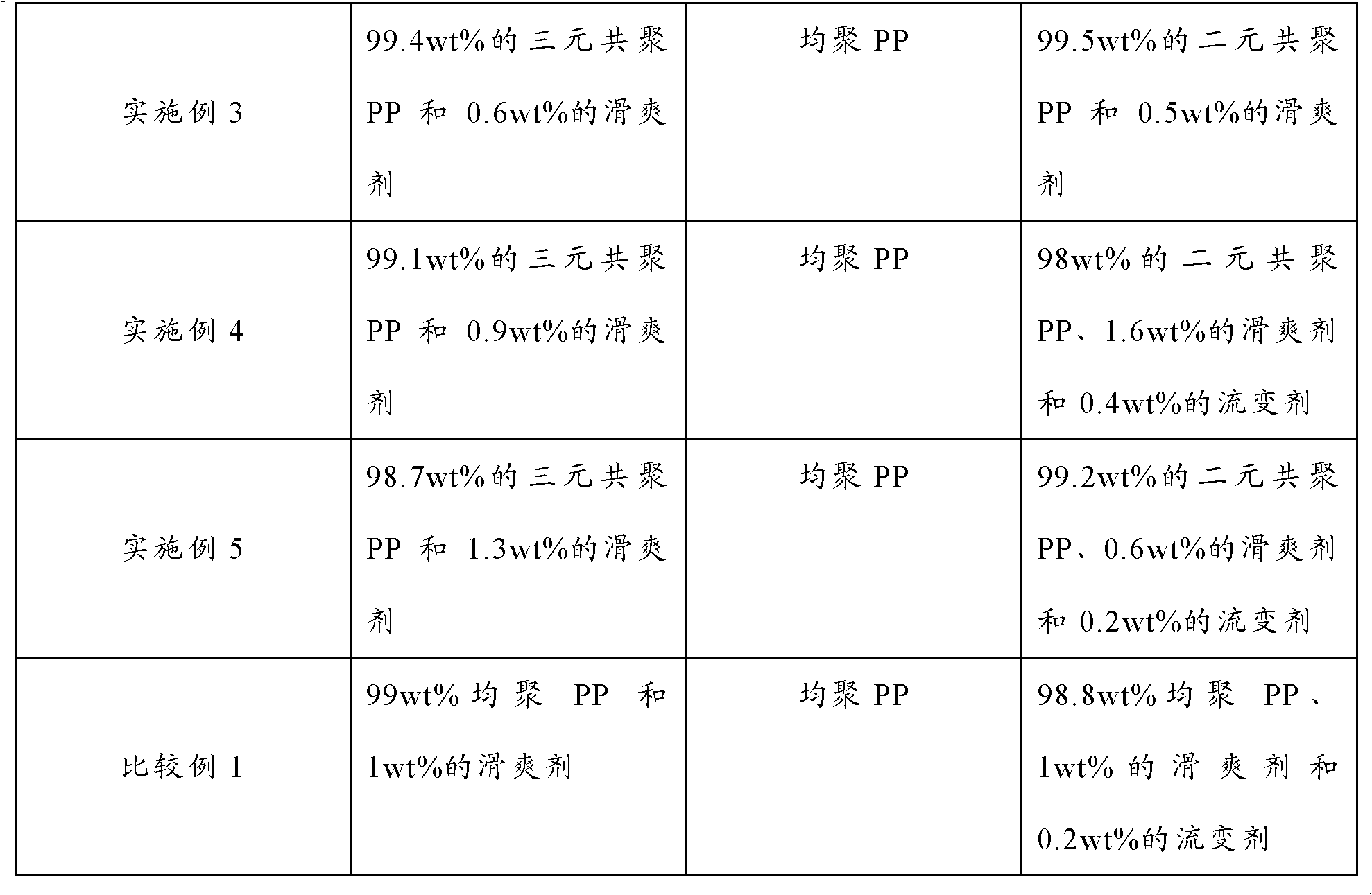

Embodiment 2~ Embodiment 5

[0053] The preparation process of the CPP film of the above example is the same as that of Example 1, the raw material formula is listed in Table 1, and the process parameters are listed in Table 2.

[0054] The total thickness of the films prepared in the above four examples is 40 μm, wherein the thickness ratio of the film outer layer, middle layer and inner layer prepared in Example 2 is 1:6:1

[0055] The thickness ratio of the film outer layer, middle layer and inner layer prepared in embodiment 3 is 1: 9: 1;

[0056] The thickness ratio of the film outer layer, middle layer and inner layer prepared in embodiment 4 is 1: 7: 1;

[0057] The thickness ratio of the outer layer, middle layer and inner layer of the film prepared in Example 5 is 1:8:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com