Vacuum vibration forming device for manufacturing artificial stones

A technology of vibration molding and artificial stone, which is applied in the direction of manufacturing tools and ceramic molding machines, which can solve the problems of difficult demoulding, uneven appearance, and low production cost, so as to prevent the generation of air holes and the sinking of solidified particles, and achieve good results. The effect of aesthetic appearance, high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

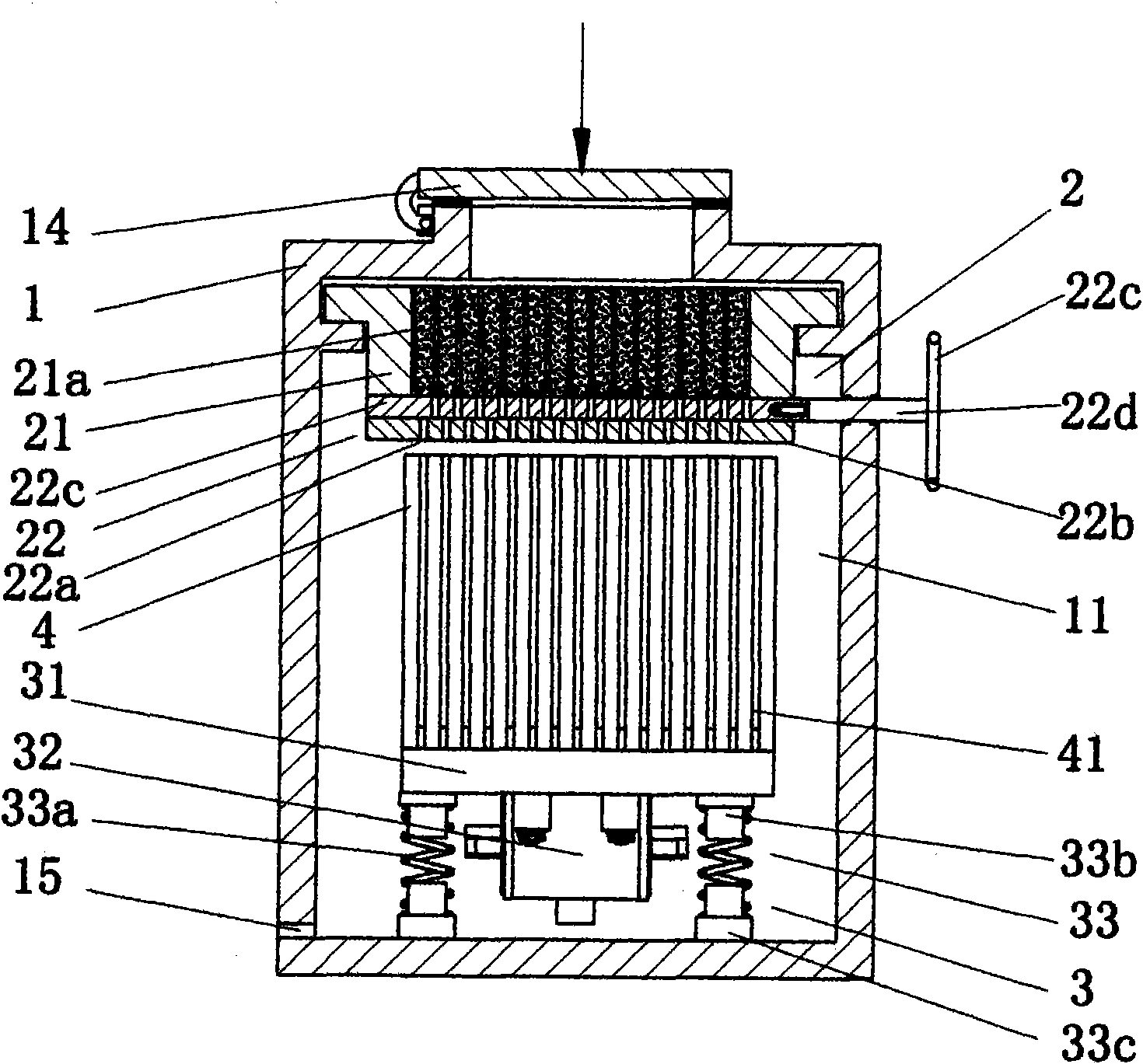

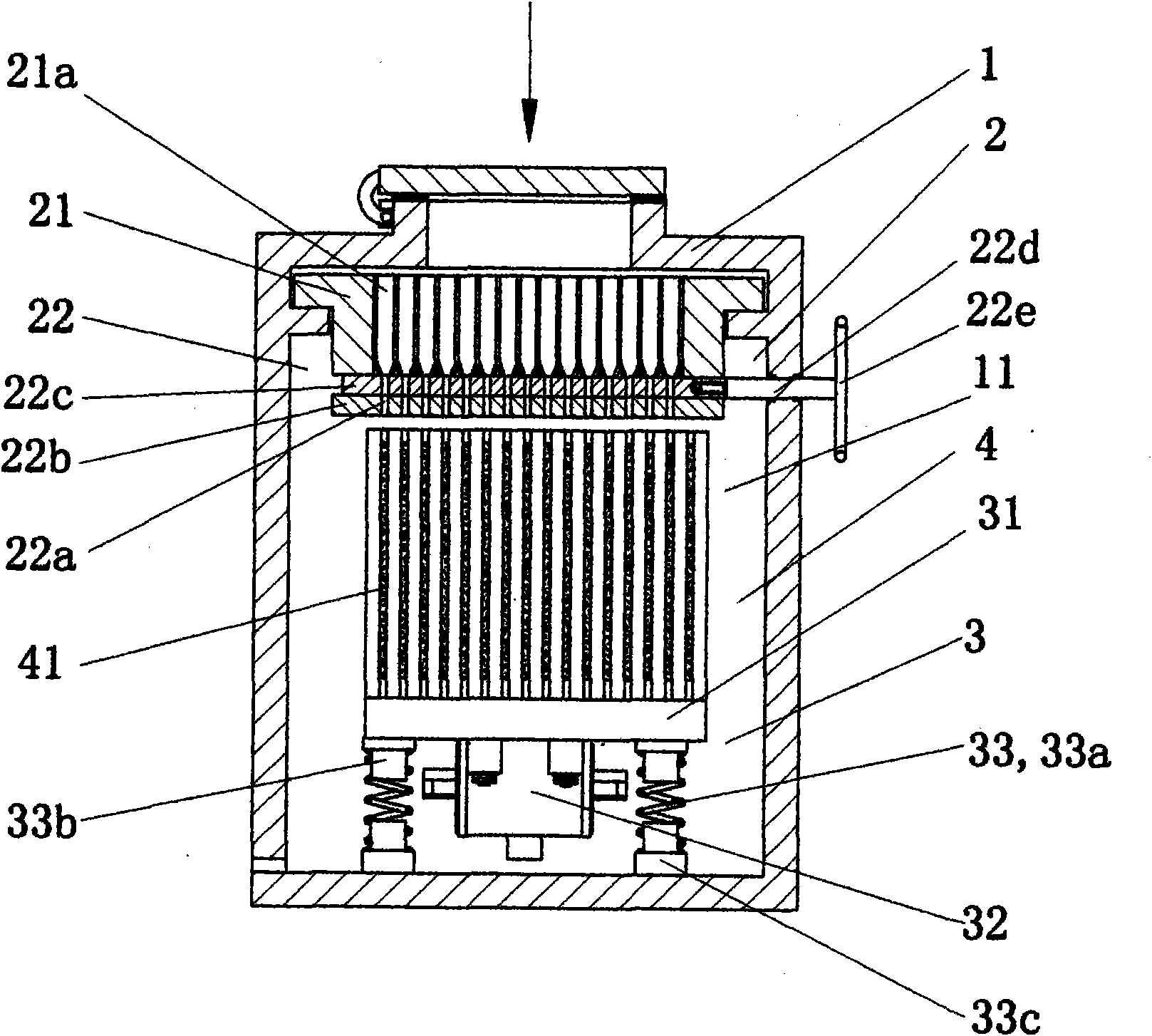

[0010] The present invention as figure 1 , figure 2 , image 3 As shown, a vacuum vibration forming device for making artificial stones comprises a box body 1, the sides of the box body 1 are provided with box doors, and the top of the box body 1 is provided with a feed port, and the box body 1 is provided with A vacuumized inner cavity 11 is provided with a filling device 2 above the inner cavity 11 near the feeding port, a vibrating table 3 is provided on the bottom surface of the inner cavity 11, and a mold 4 is arranged on the vibrating table 3 .

[0011] Above-mentioned packing device 2 comprises hopper 21, discharge plate 22, is provided with the hopper 21a that some use material plate to separate in the bucket cavity of this hopper 21, is provided with the plate surface that can correspond to each chute 21a in this discharge plate 22. Adjust the opening or closing of the discharge port 22a; the above-mentioned mold 4 is provided with mold cavities 41 arranged vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com