Modular fanless core switch

A core switch, fanless technology, applied in the field of electronics, to achieve the effect of good heat dissipation performance and good IP protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

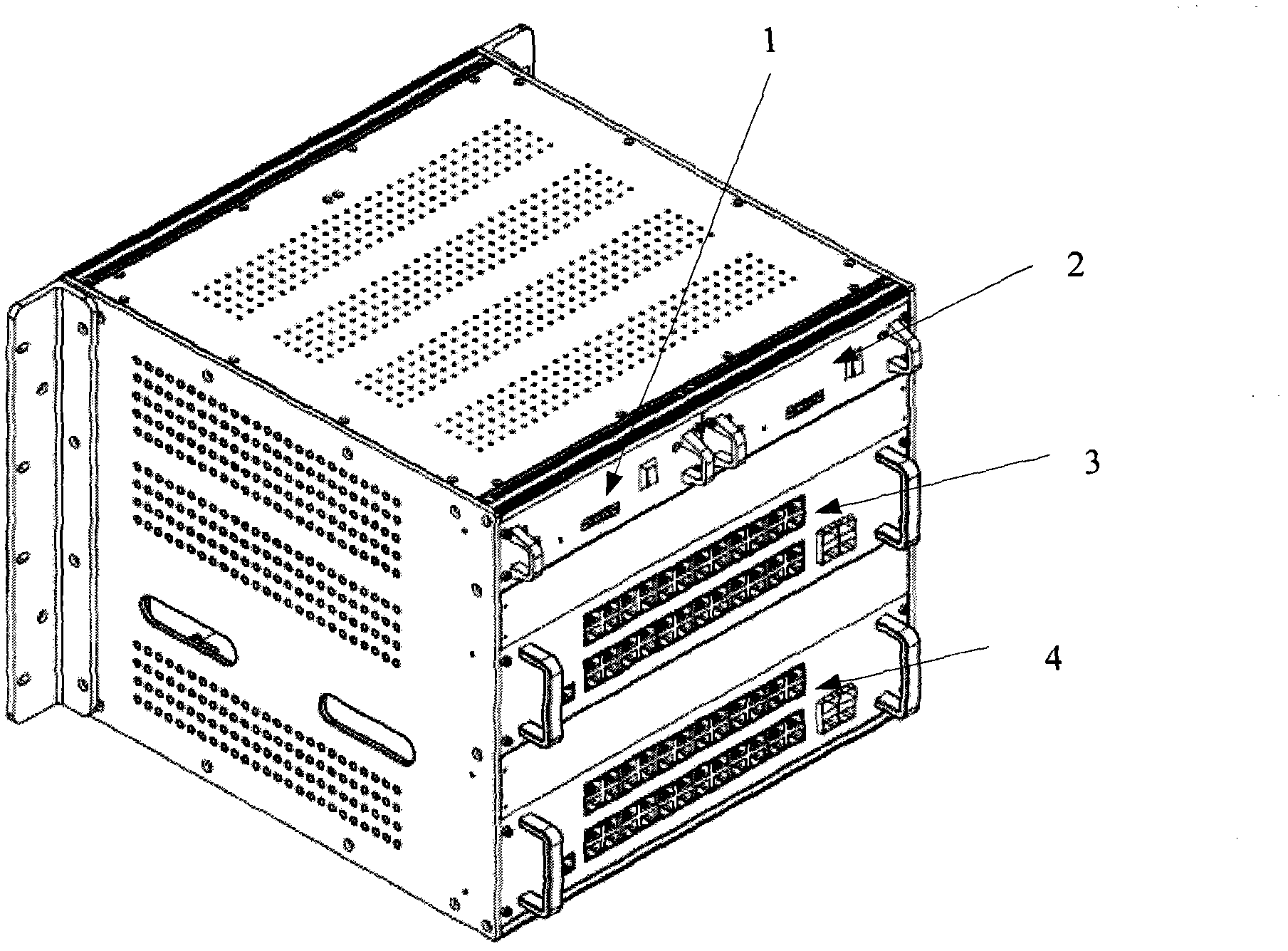

[0021] figure 1 , image 3 , Figure 4 , Image 6 , Figure 7 , indicating an 8U high-reliability switch, made of aluminum alloy, with a regular hexahedral structure, including two power modules, module 1 and module 2, and two service modules, module 3 and module 4; the service module has 100M and Gigabit interface; the upper and lower panels of the case, left and right panels have a number of small holes for ventilation and heat dissipation, and form air convection. The power module and business module can reach IP43 protection level.

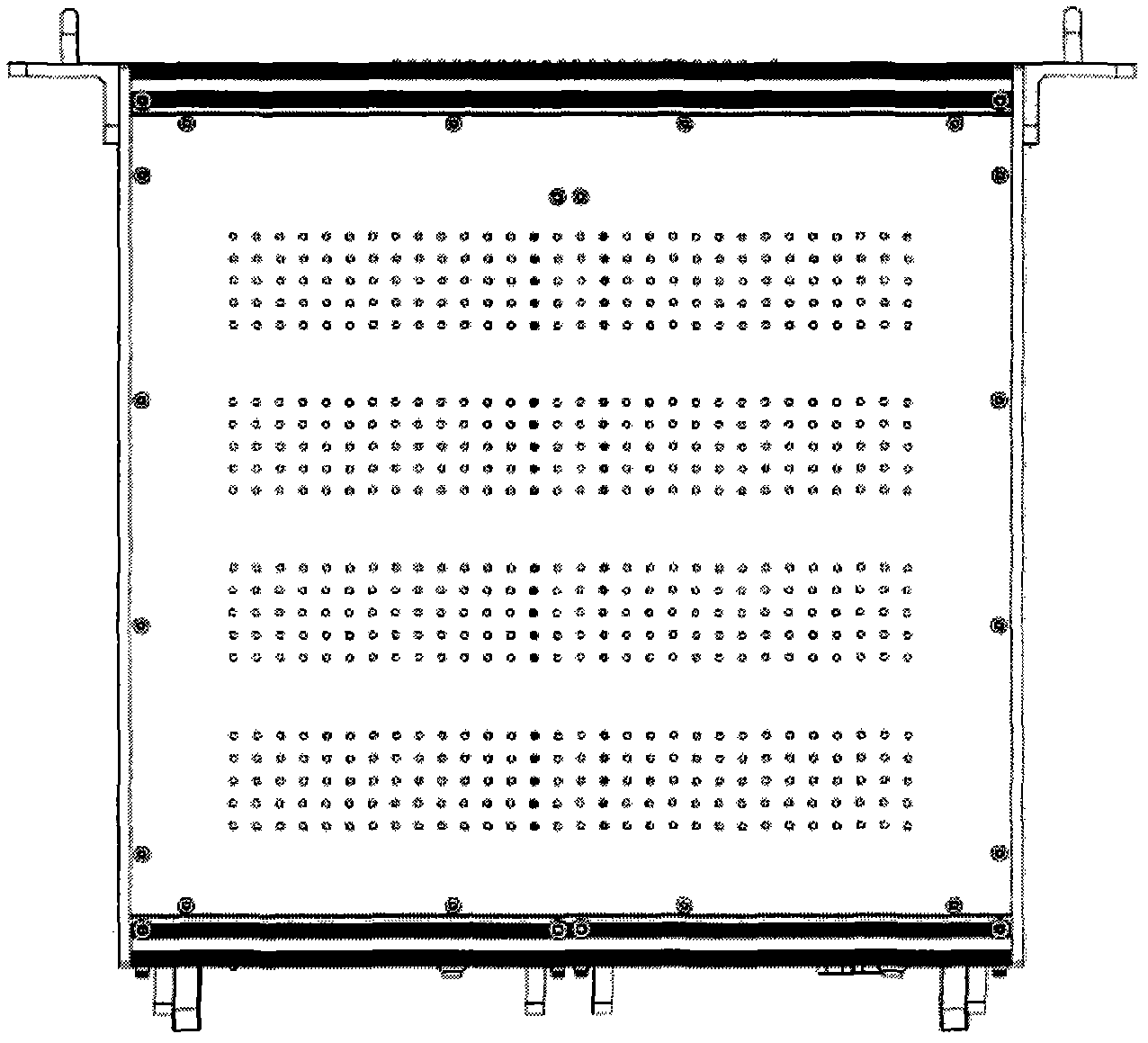

[0022] figure 2 The front panel diagram of the high-reliability switch indicates that the power module and service module are inserted into the chassis through the rails and fixed with screws 5.

[0023] Figure 5 Rear view of the high-reliability switch, indicating that the rear panel has device status indicators.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com