Operating mechanism of leakage protector

A technology of leakage protector and operating mechanism, which is applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of easy carbon deposit electrical life, iron core is easy to be stuck, etc., to improve electrical life, increase contact area, increase Large contact self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

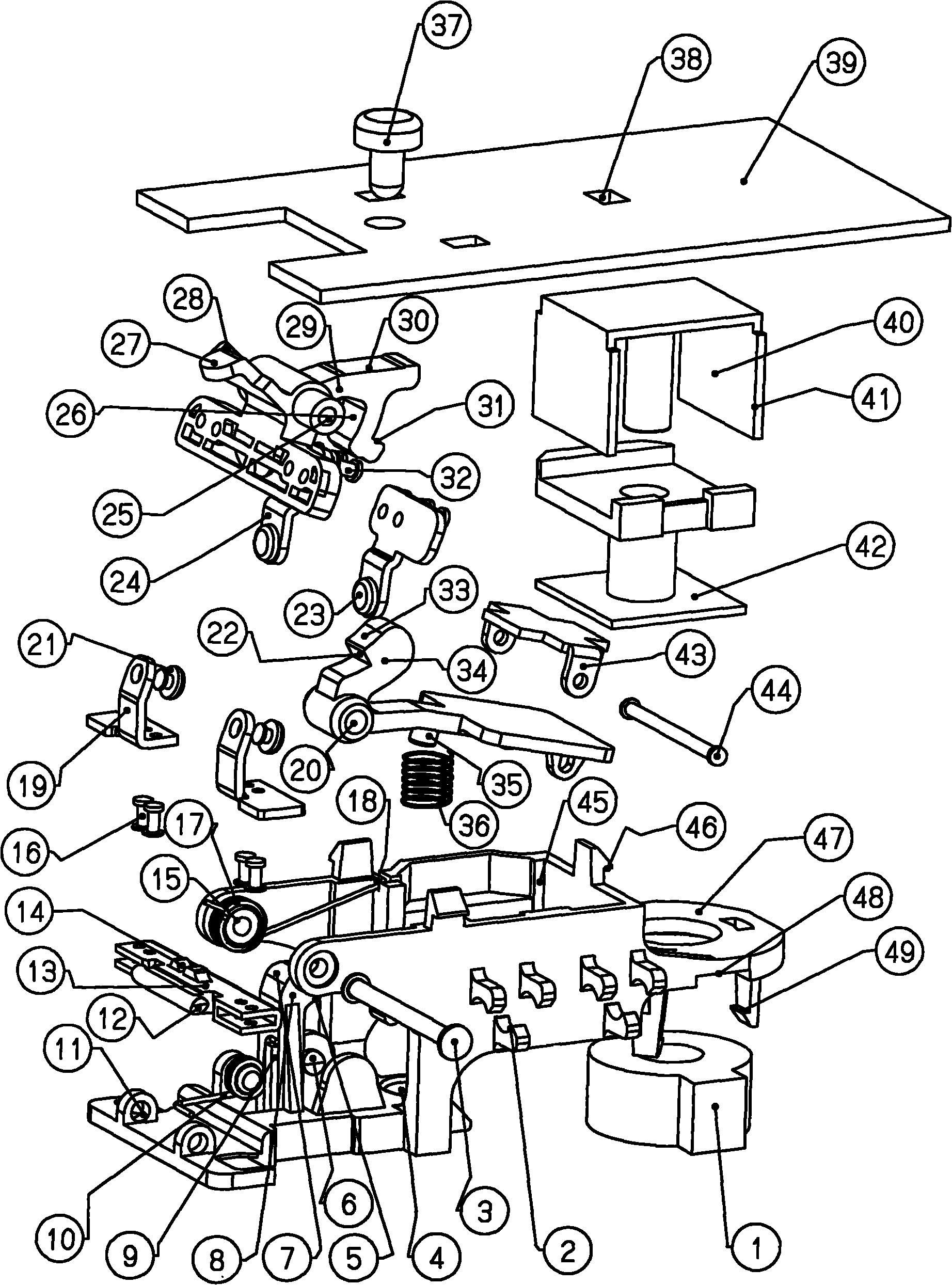

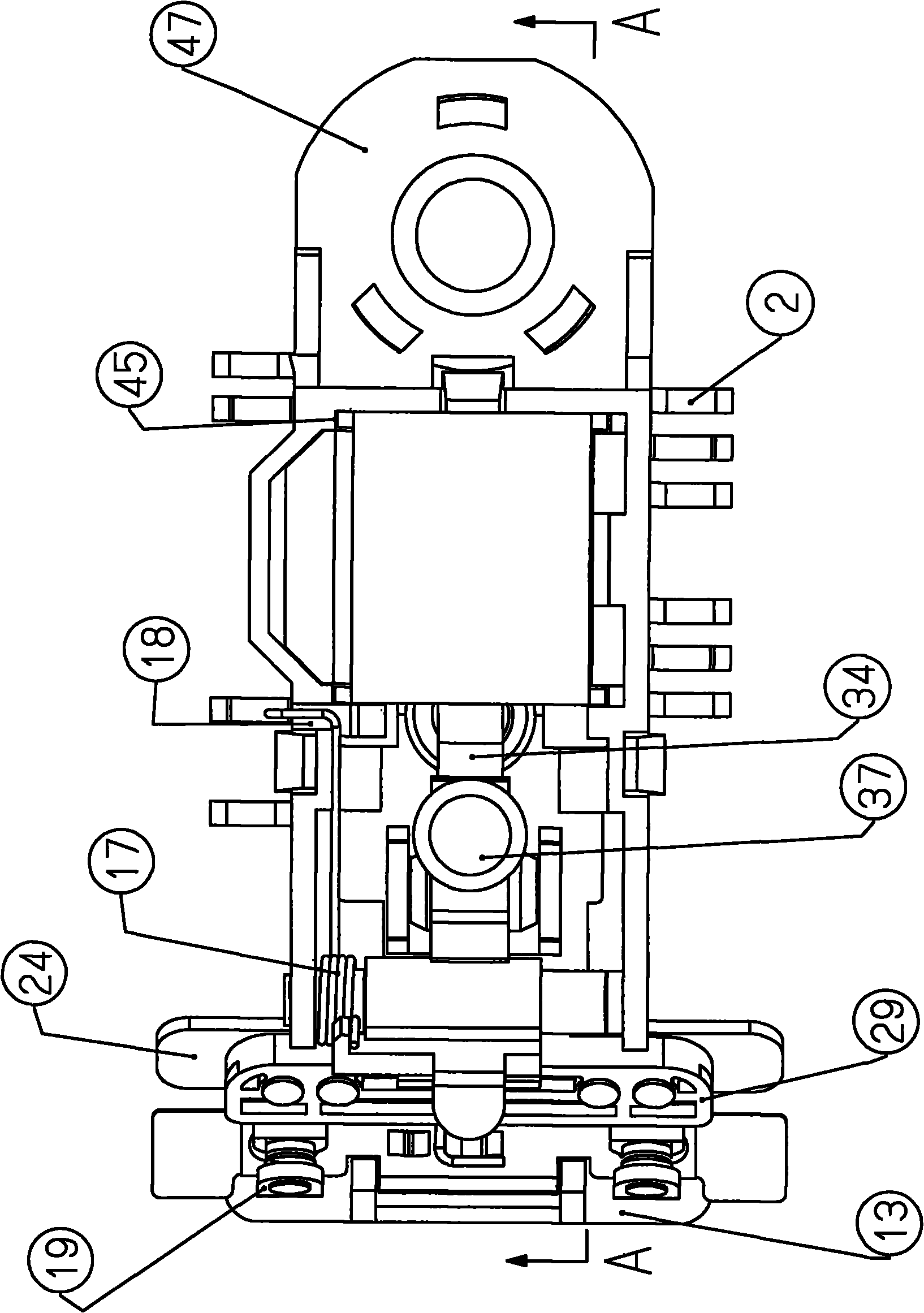

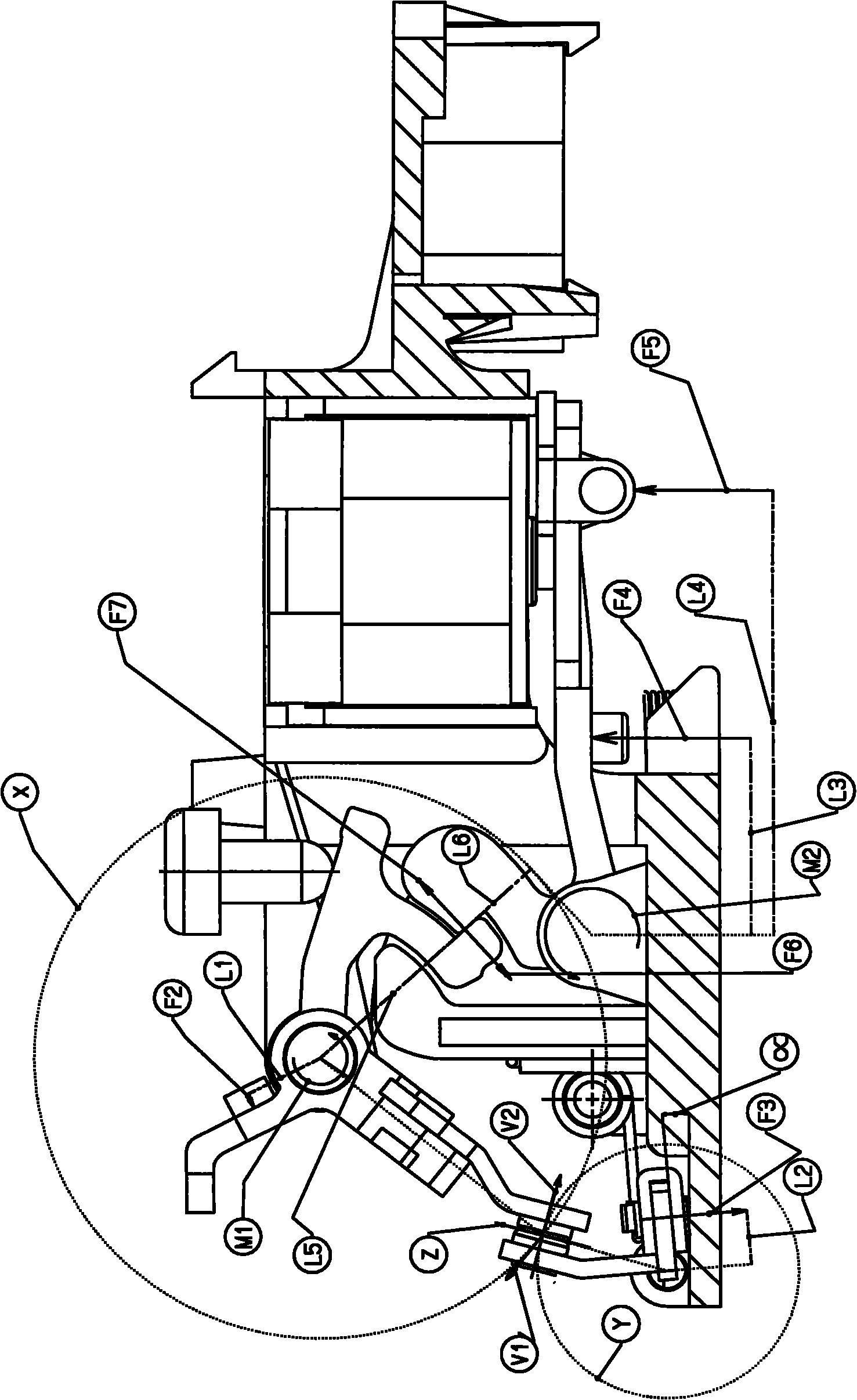

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the base 47 of the operating mechanism of the leakage protector of the present invention is provided with two coaxial active contact seat mounting holes 15 and a fan-shaped platform 8. The active contact assembly is passed through a active contact seat rivet 3 is connected with the two coaxial active contact seat mounting holes 15 provided on the base 47, and is positioned on the fan-shaped platform 8 through the active contact seat spring 17. The active contact assembly includes an active The contact seat 29, the two sides of the active contact seat 29 are respectively provided with an active contact plate 24, respectively connected to the active contact seat 29 through two active contact plate rivets 32, and the active contact plate 24 is respectively A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com