Unthreaded terminal mechanical explosion-proof dry type capacitor

A threadless and capacitor technology, applied in the direction of capacitors, fixed capacitors, fixed capacitor shells/packages, etc., can solve the problems of not being able to meet different products, unsafe, exposed electrodes, etc., to achieve convenient use, improve product performance, and ensure insulation strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

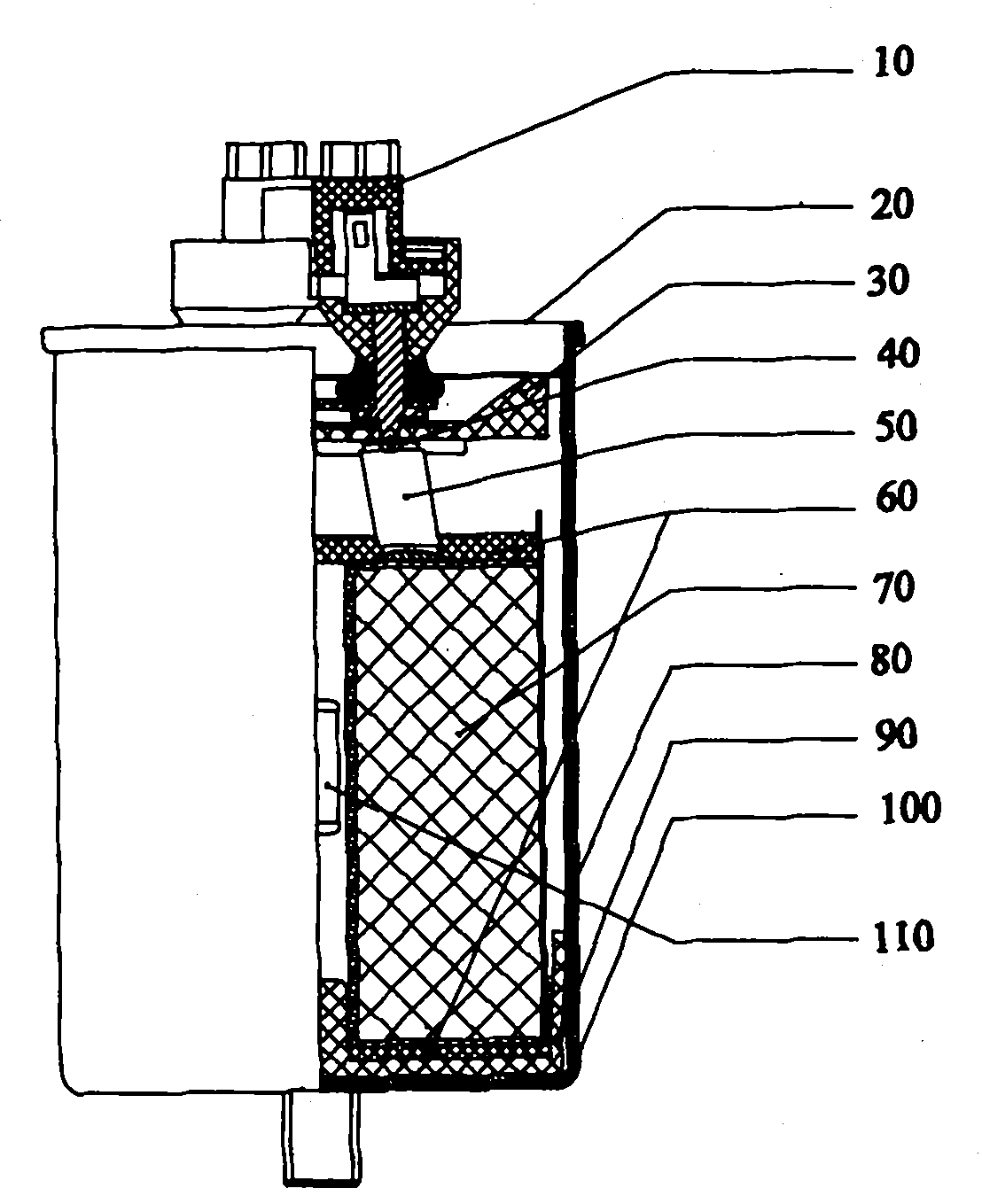

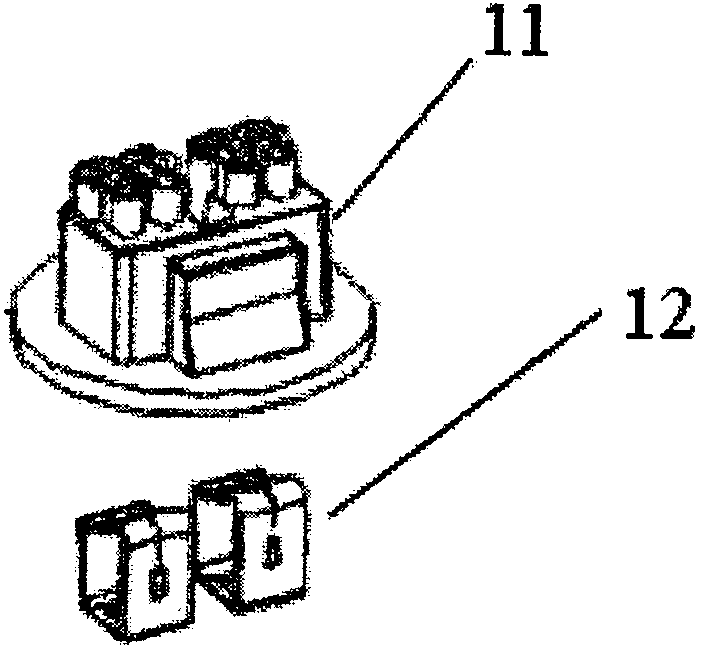

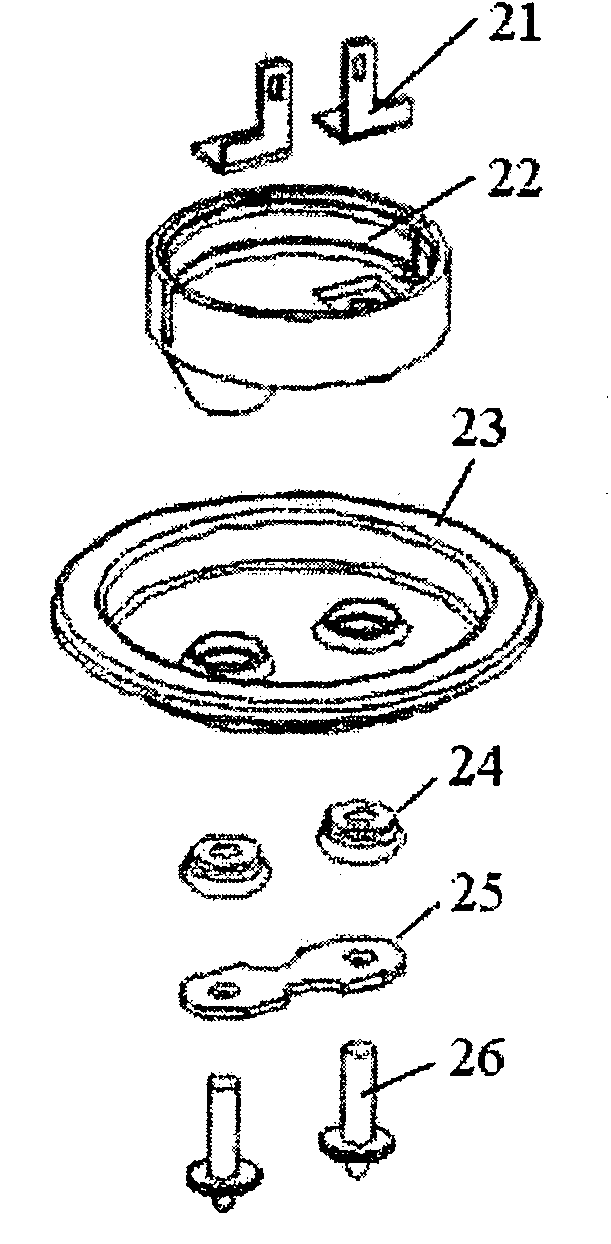

[0020] A screwless terminal mechanical explosion-proof dry capacitor, the structure of which is as follows figure 1 As shown: the capacitor includes a terminal assembly 10, a cover assembly 20, a burst plate 30, a copper foil 40, an insulating sleeve 50, a core assembly 70, an insulating paper 80, a bottom sleeve 90, a shell 100 and a discharge resistor 110, and the terminal assembly 10 The structure is as figure 2 As shown, it includes a screwless terminal 11 and a double insertion reed 12, the double insertion reed 12 is placed in the screwless terminal 11, and the structure of the cover assembly 20 is as follows image 3 As shown, it includes an insert 21, a single bowl 22, a cover 23, a sealing ring 24, an insulating plate 25 and a rivet 26, and the rivet 26 is sequentially covered with an insulating plate 25 and a sealing ring 24, and the cover 23 and the single bowl 22 are connected by the rivet 26 , the insert piece 21 is set in the single bowl 22, the copper foil 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com