Three-piece type single-stage cycloid reducer of industrial robot

A technology of industrial robot and cycloid reducer, which is applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of high manufacturing precision and the inability to automatically compensate for the backlash of the meshing surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

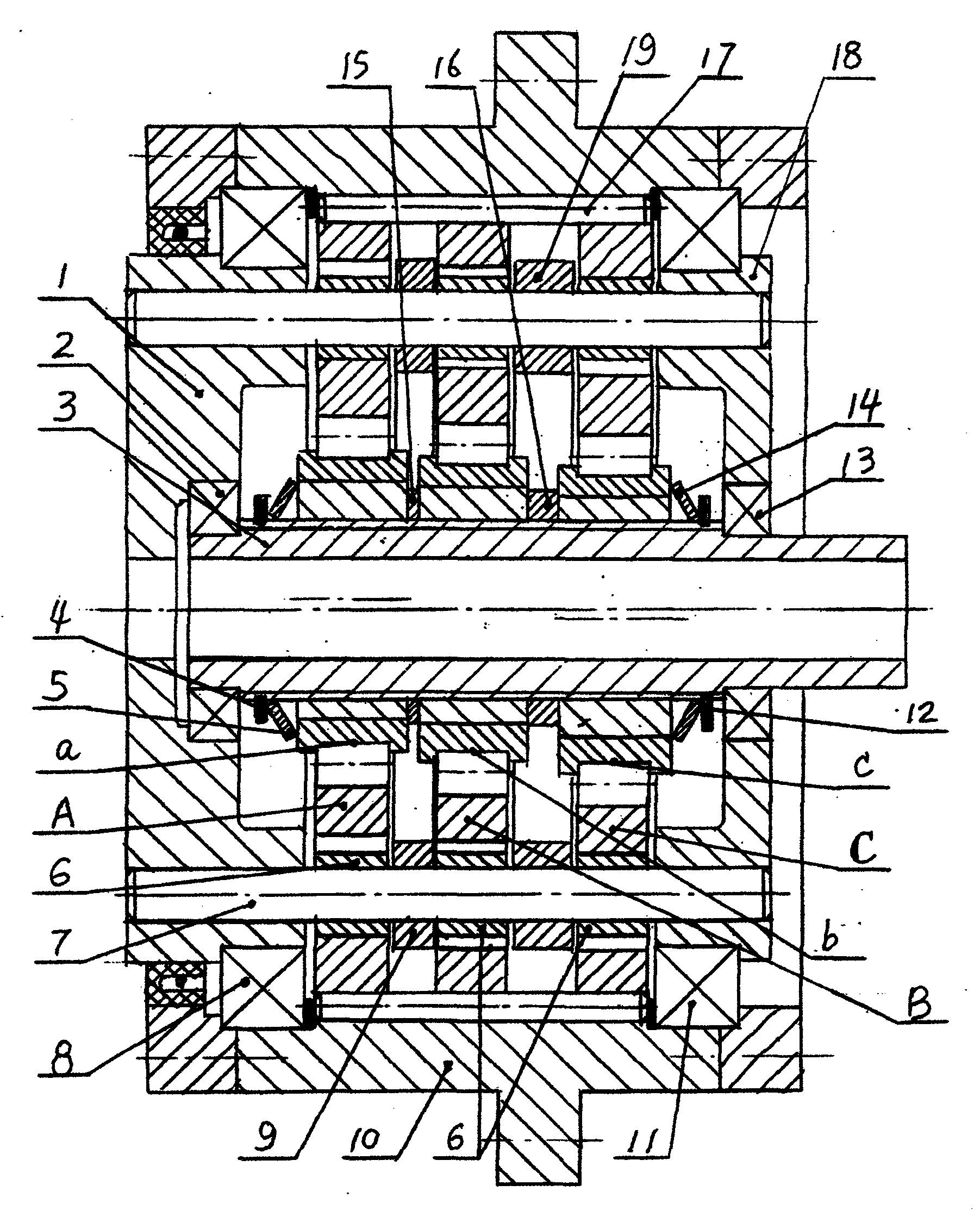

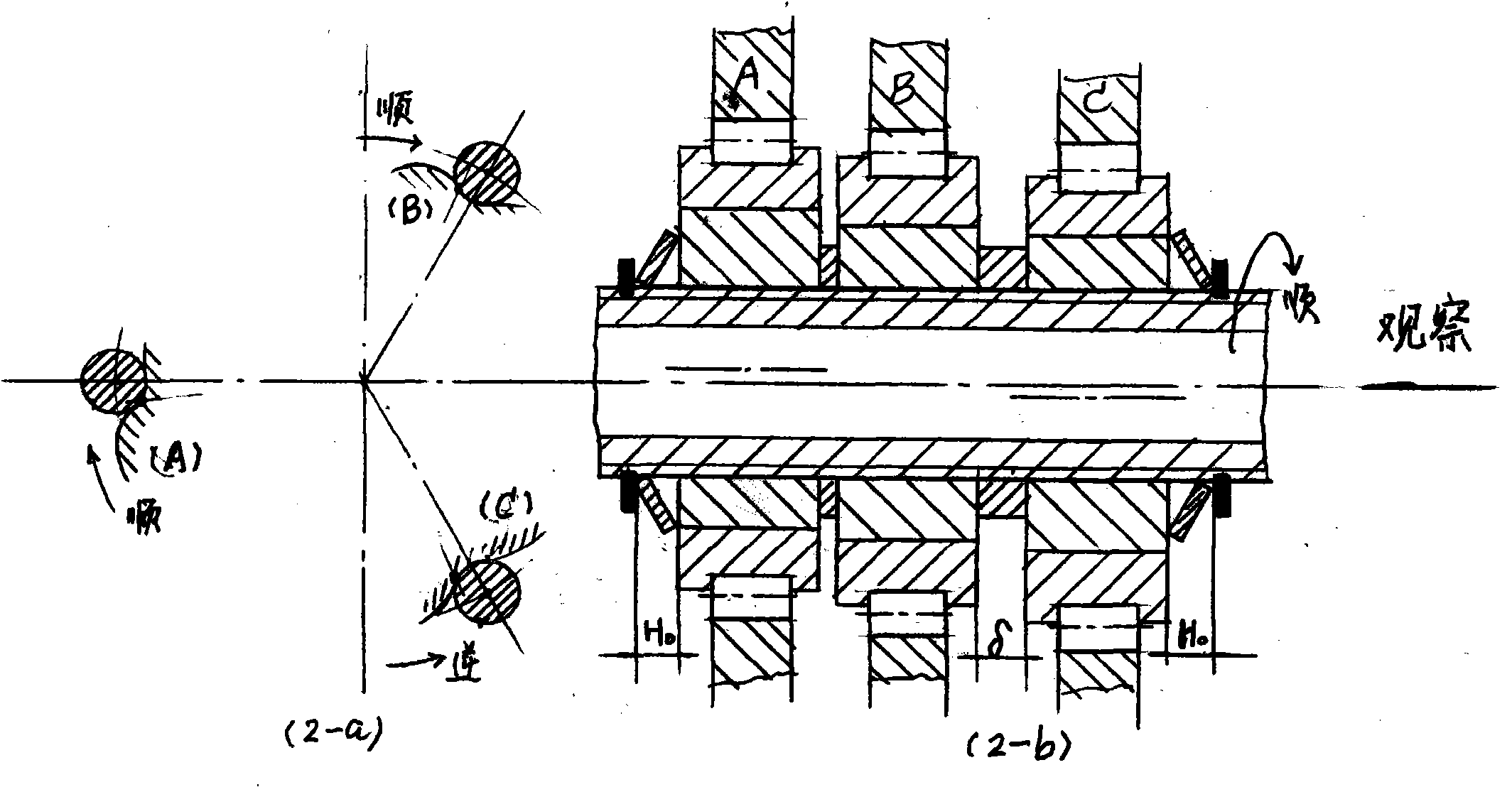

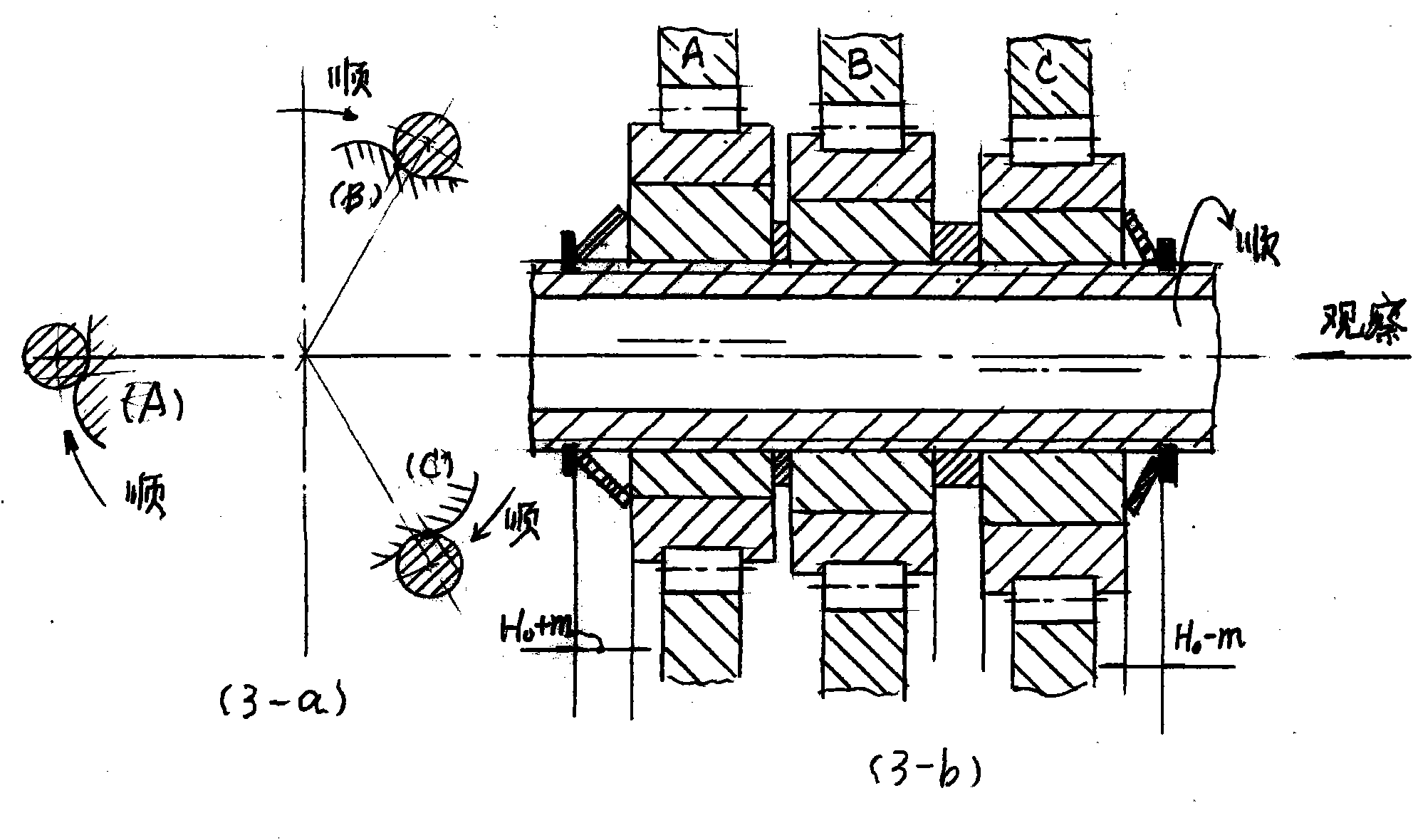

[0026] refer to figure 1 , 2 and 3. A three-piece single-stage cycloid reducer for an industrial robot, consisting of three cycloid gears A, B and C, an eccentric bearing installed in an inner hole, a pin-tooth shell (10), a pin-tooth pin (17) ), a column pin (7), a column sleeve (6), an input shaft (3) and a W output mechanism, characterized in that:

[0027] (a) The input shaft (3) is coaxially output by the W output mechanism through the single-stage deceleration of the cycloid wheel;

[0028] (b) The W output mechanism consists of a left frame (1), a right frame (18), a column pin (7) and a column sleeve (6). The left and right frames are respectively supported by bearings (8) and (11) in the inner holes on both sides of the pin gear housing (10), and the two ends of the input shaft (3) are supported by bearings (2) and (13) respectively. Supported in the inner holes of the left and right frames, the W output mechanism adopts a rigid cage structure with a large diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com