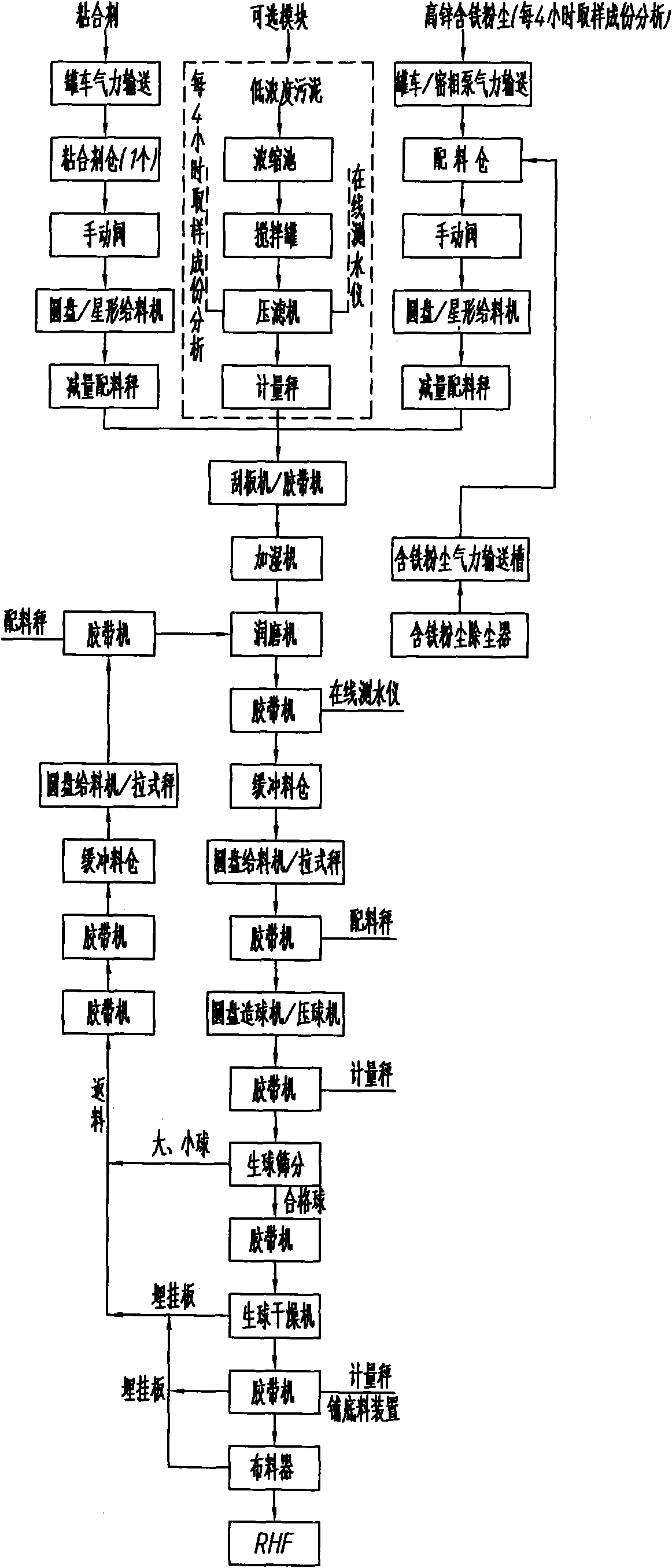

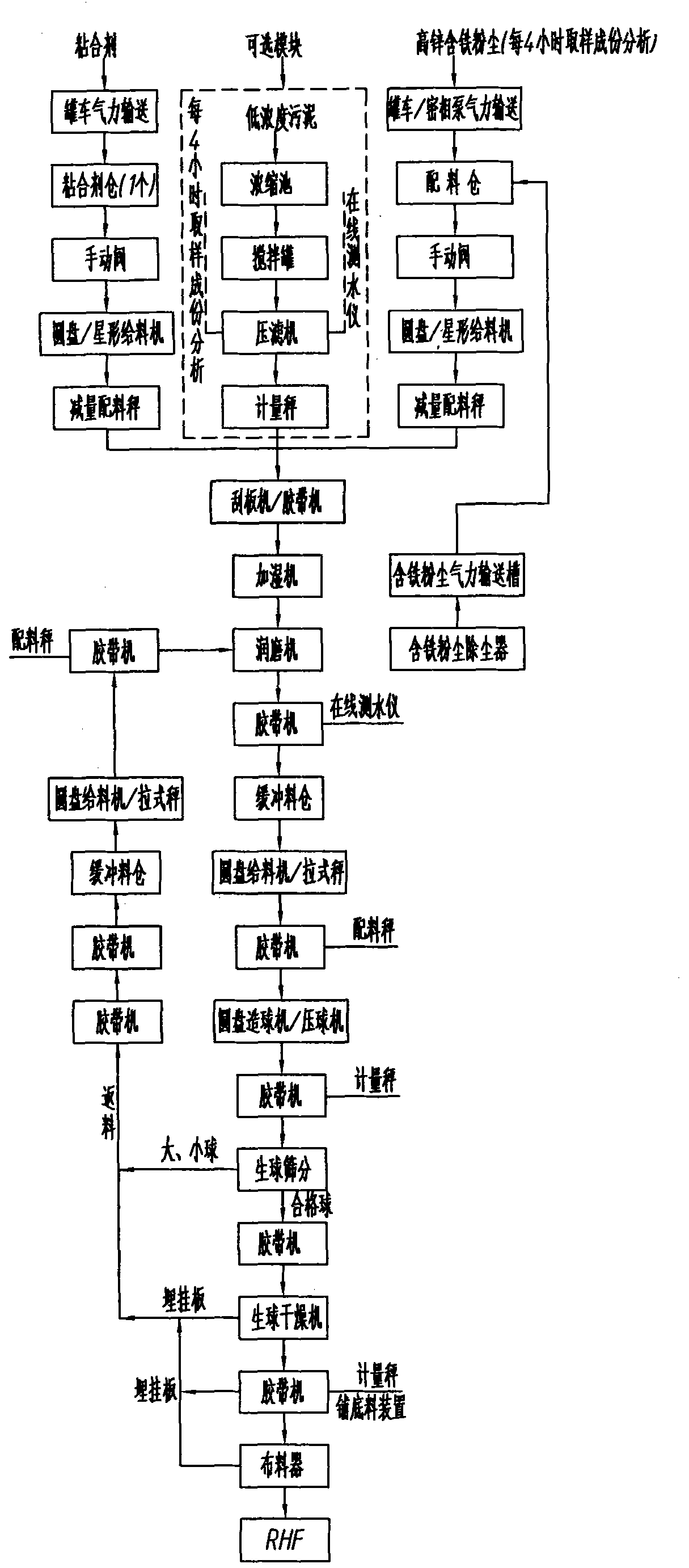

Raw material treatment and pelletizing system process for rotary hearth furnace

A technology of raw material processing and rotary hearth furnace, which is applied in the direction of improving process efficiency, etc., to achieve the effects of clean environment, increased particle size and specific surface area, and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

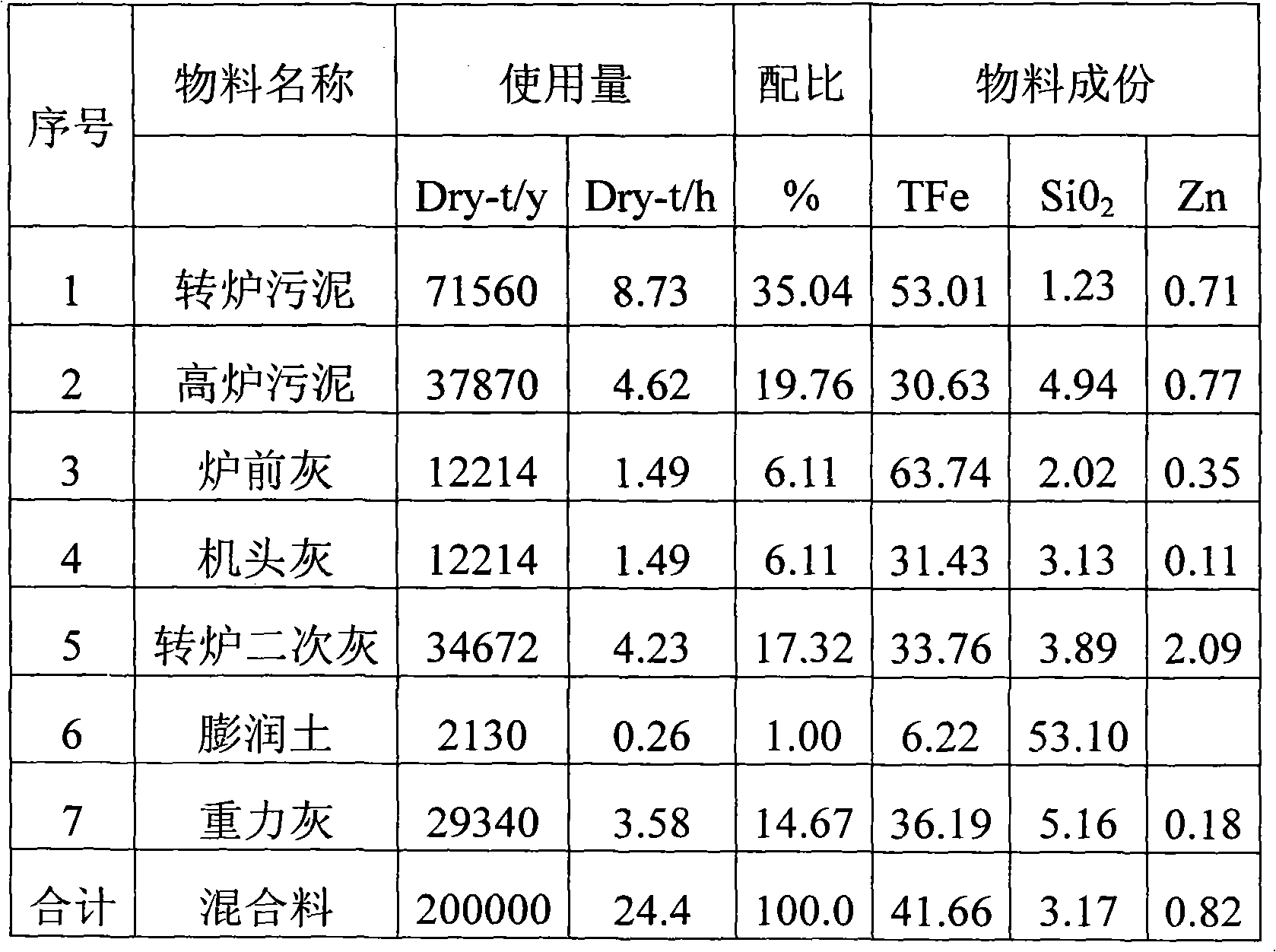

[0014] First of all, the various high-zinc iron-containing dusts to be processed by this system are batched, that is, the various high-zinc iron-containing dusts in the tanker are sent to the sealed batching bin by compressed air and pipelines on the spot, and the dust is at the lower mouth of the batching bin. The batching is carried out through a system consisting of a feeder and a weight reduction scale; at the same time, the adhesive required for pelletizing in the tanker is sent to the sealed adhesive bin using compressed air and pipelines on the spot, and the adhesive is being bonded. The lower mouth of the agent silo carries out ingredients through a system composed of a feeder and a weight reduction scale. Then the high-zinc iron-containing dust mixture and the adhesive mixture are sent to the humidifier through the belt conveyor for preliminary humidification and mixing. Then the preliminarily humidified and homogenized mixture and the unqualified balls in the subseque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com