Method for smelting low-phosphorous molten steel by utilizing semisteel

A technology of steel smelting and molten steel, which is applied in the direction of improving process efficiency and manufacturing converters, etc. It can solve problems such as complex formula, insufficient dephosphorization depth, poor control of end-point phosphorus return, etc., and achieves the effect of easy control and reduction of phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

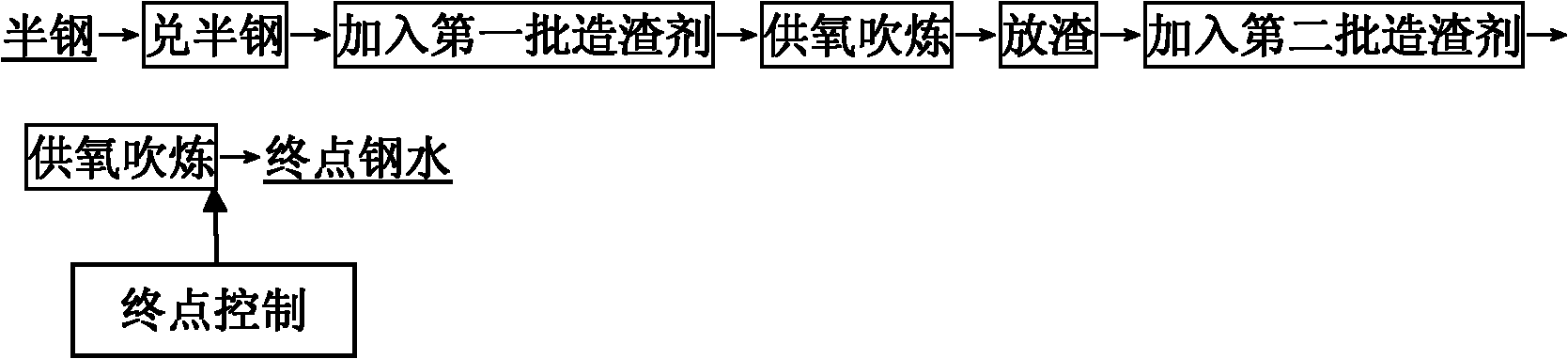

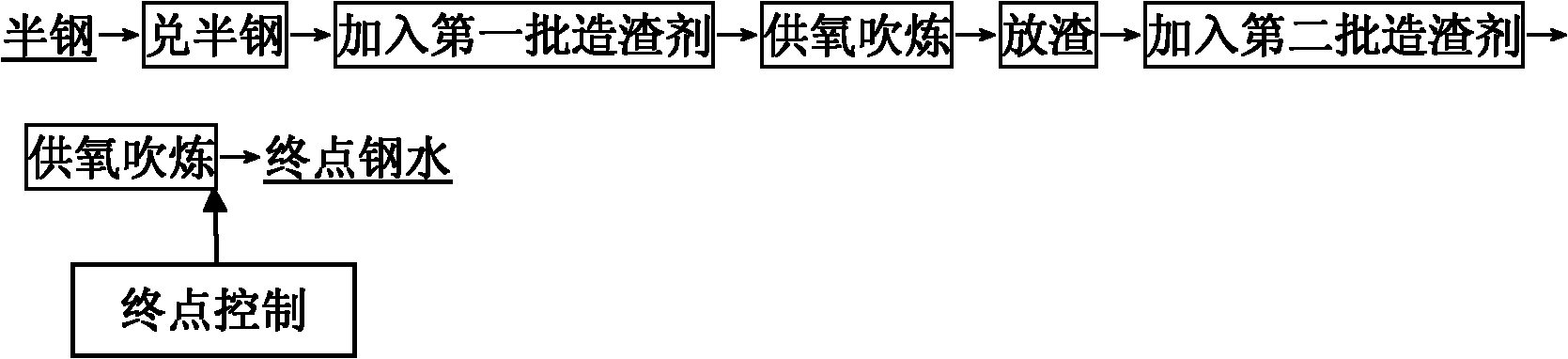

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 uses the method of the present invention to smelt low-phosphorus molten steel

[0035] Prepare to extract vanadium semi-steel after desulfurization and slag removal, its composition is: C 3.7%, Mn 0.032%, V 0.03%, S 0.008%, P 0.067%, the balance is Fe, the above are weight percentages, and the sum of percentages is 100%; then add 140t of the semi-steel into the converter, add the first batch of slagging agents (lime 3500kg, high magnesium lime 2000kg, composite slag 3050kg) into the converter after the semi-steel is mixed into the converter, and the alkalinity in the converter is controlled At 2.3~2.8, blowing for 5 minutes (oxygen supply intensity: 3.5~3.8m 3 / min.t -1 Semi-steel, bottom blowing argon or nitrogen intensity 0.05~0.08m 3 / min.t -1 Stirring effect), then shake the converter for slagging, and then add the second batch of slagging agent (lime 4000kg, high magnesium lime 2500kg, composite slag 1910kg) for oxygen blowing (oxygen supply intensi...

Embodiment 2

[0036] Embodiment 2 uses the method of the present invention to smelt low-phosphorus molten steel

[0037] Prepare the vanadium-extracted semi-steel after desulfurization and slag removal, its composition is: C 3.7%, Mn 0.032%, V 0.03%, S 0.008%, P0.067%, the balance is Fe, and the above are weight percentages, percentages The sum is 100%; then 140t of the semi-steel is blended into the converter, and after the semi-steel is blended into the converter, the first batch of slag-forming agents (3200kg of lime, 1800kg of high-magnesia lime, and 2770kg of composite slag) are added to the converter. The temperature is controlled at about 2.5 (2.3~2.8), blowing for 5 minutes (oxygen supply intensity: 3.5~3.8m 3 / min.t -1 Semi-steel, bottom blowing argon or nitrogen intensity 0.05~0.08m 3 / min.t -1 Stirring effect), shake the converter for slagging, and then add the second batch of slagging agent (lime 3800kg, high magnesium lime 2300kg, composite slag 1800kg) for oxygen blowing (o...

Embodiment 3

[0038] Embodiment 3 uses the method of the present invention to smelt low-phosphorus molten steel

[0039] Prepare the vanadium-extracted semi-steel after desulfurization and slag removal, its composition is: C 3.7%, Mn 0.032%, V 0.03%, S 0.008%, P0.067%, the balance is Fe, and the above are weight percentages, percentages The sum is 100%; then 140t of the semi-steel is blended into the converter, and after the semi-steel is blended into the converter, the first batch of slagging agents (lime 3000kg, high-magnesia lime 1500kg, and composite slag 2520kg) are added to the converter. Controlled at 2.3-2.8, blowing for 5 minutes (oxygen supply intensity: 3.5-3.8m 3 / min.t -1 Semi-steel, bottom blowing argon or nitrogen intensity 0.05~0.08m 3 / min.t -1 Stirring effect), shake the converter for slagging, and then add the second batch of slagging agent (lime 3500kg, high magnesium lime 2000kg, composite slag 1670kg) for oxygen blowing (oxygen supply intensity: 3.5 ~ 3.8m 3 / min.t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com