Formula of PE (Poly Ethylene) wood plastic composite material of imitation wood grain surface and manufacture process thereof

A technology of wood-plastic composite material and production method, which is applied in the field of PE wood-plastic composite material composition, can solve the problems of non-abrasion resistance, difficulty in achieving uniformity, single appearance texture, etc., and achieve the effect of beautiful texture and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

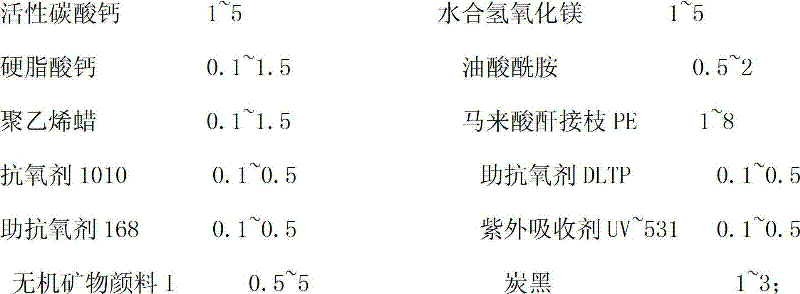

[0024] Embodiment 1, the composition of described masterbatch I and the list of parts by weight are as follows:

[0025]

[0026] The composition and weight proportion of described masterbatch II are:

[0027]

[0028]

[0029] The melt flow index (MI) of the HDPE regrind I is 0.05-0.2g / 10min, the melt flow index (MI) of the HDPE regrind II is 0.2-1.5g / 10min, and the recycled leftover plants The melt flow index (MI) of the fiber powder is 0.05-0.2g / 10min.

Embodiment 2

[0030] Embodiment two, the composition of described masterbatch I and the list of parts by weight are as follows:

[0031]

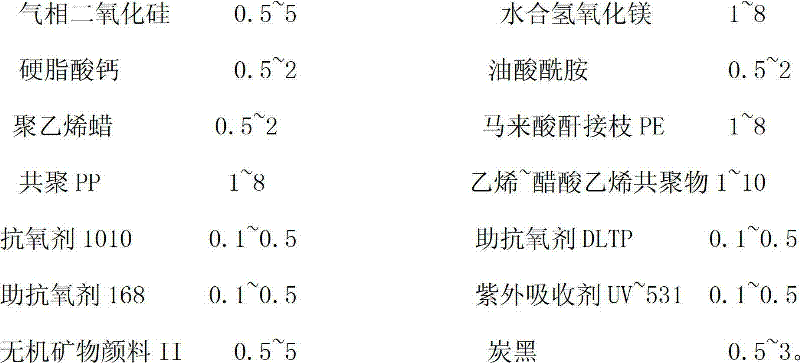

[0032] The composition and weight proportion of described masterbatch II are:

[0033]

[0034]

[0035] The melt flow index (MI) of the HDPE regrind I is 0.05-0.2g / 10min, the melt flow index (MI) of the HDPE regrind II is 0.2-1.5g / 10min, and the recycled leftover plants The melt flow index (MI) of the fiber powder is 0.05-0.2g / 10min.

Embodiment 3

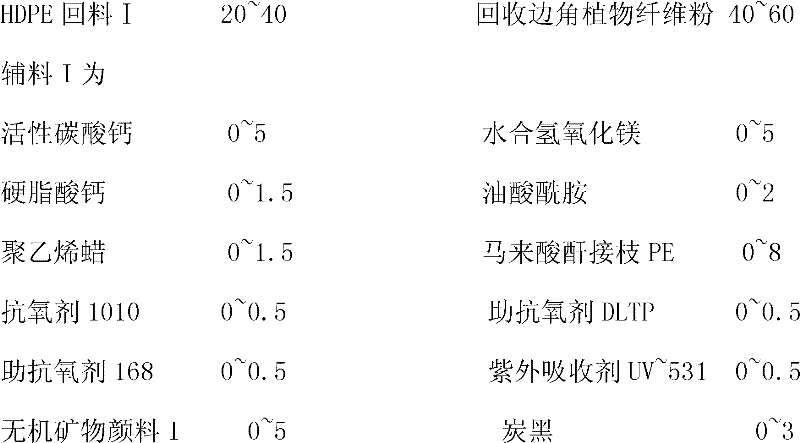

[0036] Embodiment three, the composition of described masterbatch I and the list of parts by weight are as follows:

[0037]

[0038] The composition and weight proportion of described masterbatch II are:

[0039]

[0040]

[0041] The melt flow index (MI) of the HDPE recycled material I is 0.05-0.2g / 10min, such as the melt flow index (MI) of the HDPE recycled material II is 0.2-1.5g / 10min, and the recycled corner The melt flow index (MI) of the plant fiber powder is 0.05-0.2g / 10min. The melt flow index (MI) of the HDPE recycled material I is preferably 0.05-0.2 g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com