Electronic component inspecting method and apparatus used in the method

A technology for electronic components and inspection methods, applied in measurement devices, instruments, material analysis by optical means, etc., can solve the problems of high-speed limitation, difficulty in accurately measuring distance, and time-consuming adjustment, and achieve high-speed operation. , to achieve the effect of miniaturization and shortening of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, the best mode for carrying out the present invention will be described.

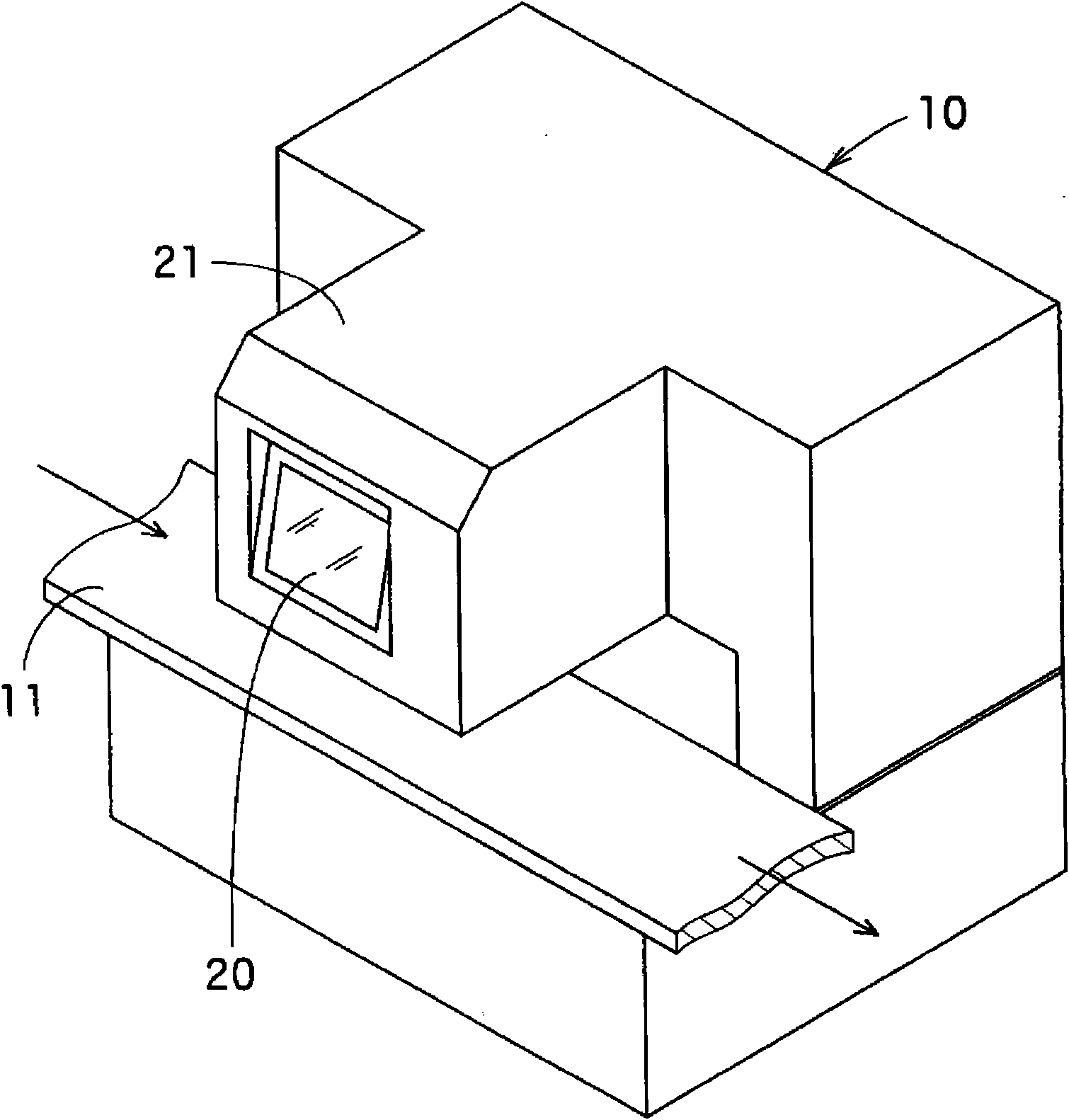

[0045] figure 1 It is an external perspective view showing one embodiment of the electronic component inspection apparatus of the present invention. This inspection device 10 is arranged on the side of the conveyer belt 11 that is connected with the LCD assembly production line, and the manufactured LCD assemblies are taken in from the conveyer belt 11 to the stage in the inspection device 10 for inspection, and then the inspected The last LCD assembly returns to the conveyor belt 11. In addition, reference numeral 20 is a monitor screen for displaying images obtained during the above inspection, and reference numeral 21 is a main body including a control management unit for controlling the operation of the device and an information processing unit for inspection.

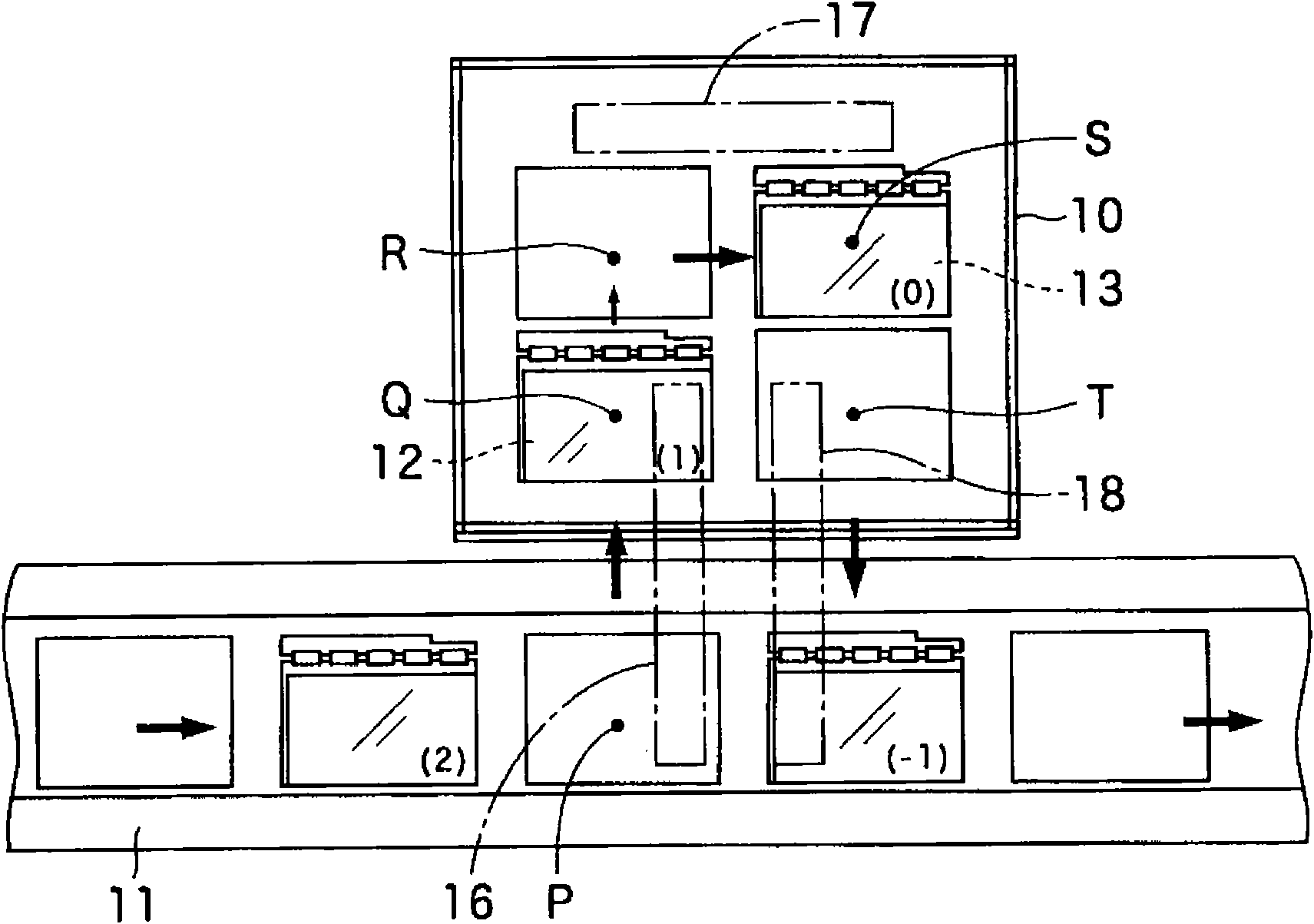

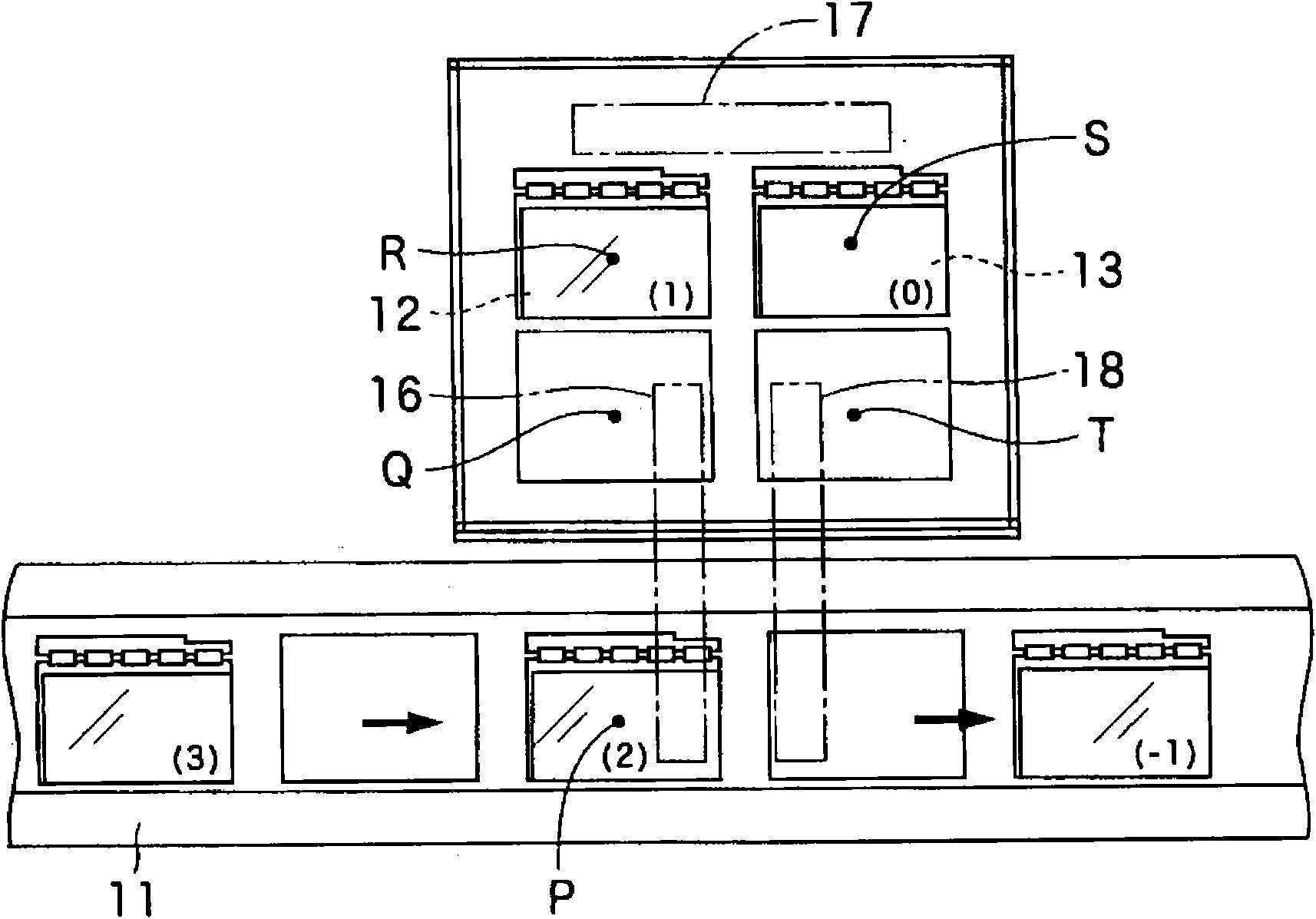

[0046] And, if Figure 2A As shown, in this inspection device, two stages 12 and 13 for inspection are arranged in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com