UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

A mixed matrix membrane and polymer technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, membranes, etc., can solve the problems of compatibility and adhesion of inorganic molecular sieve/polymer interface materials that have not been completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

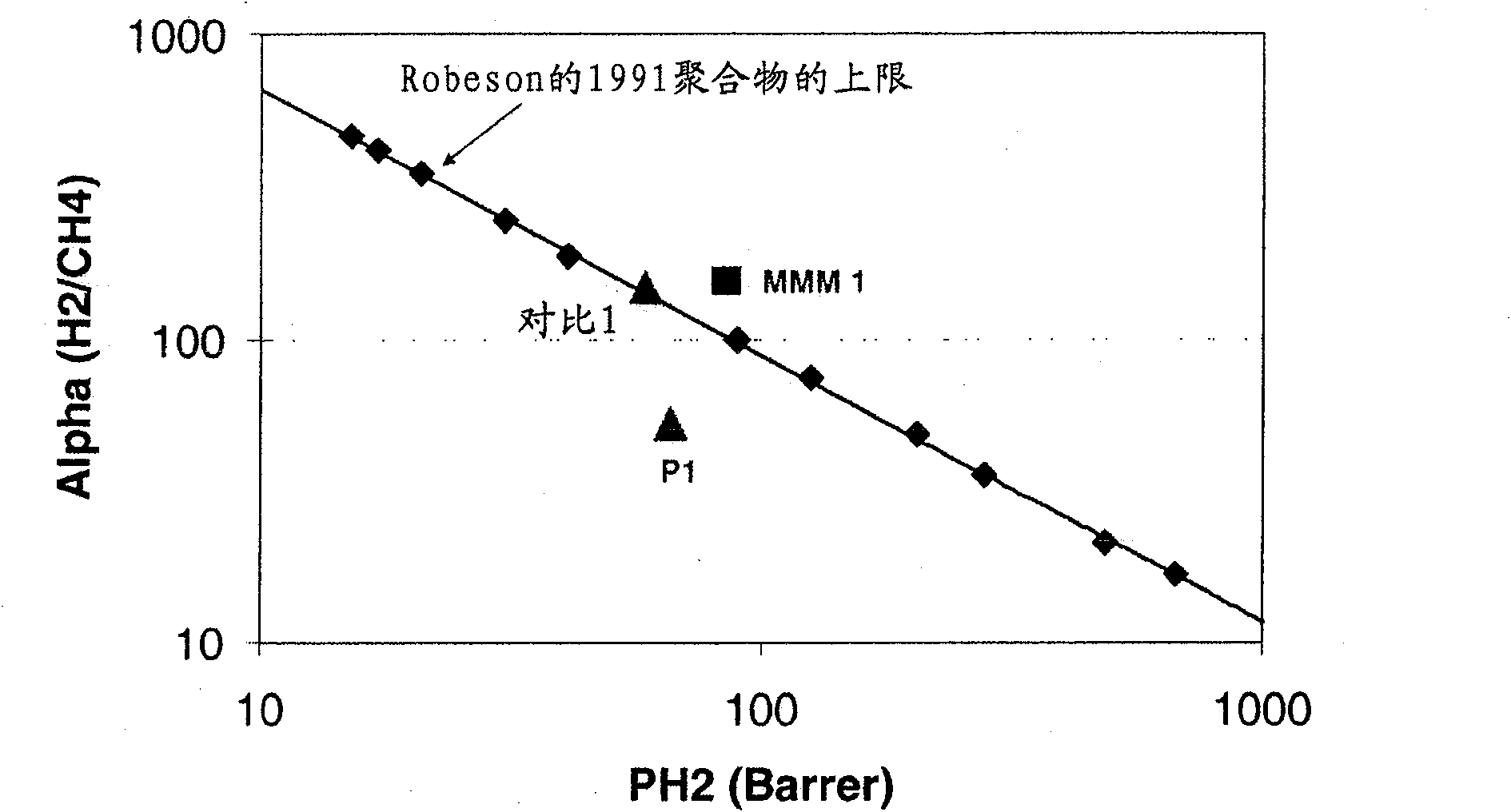

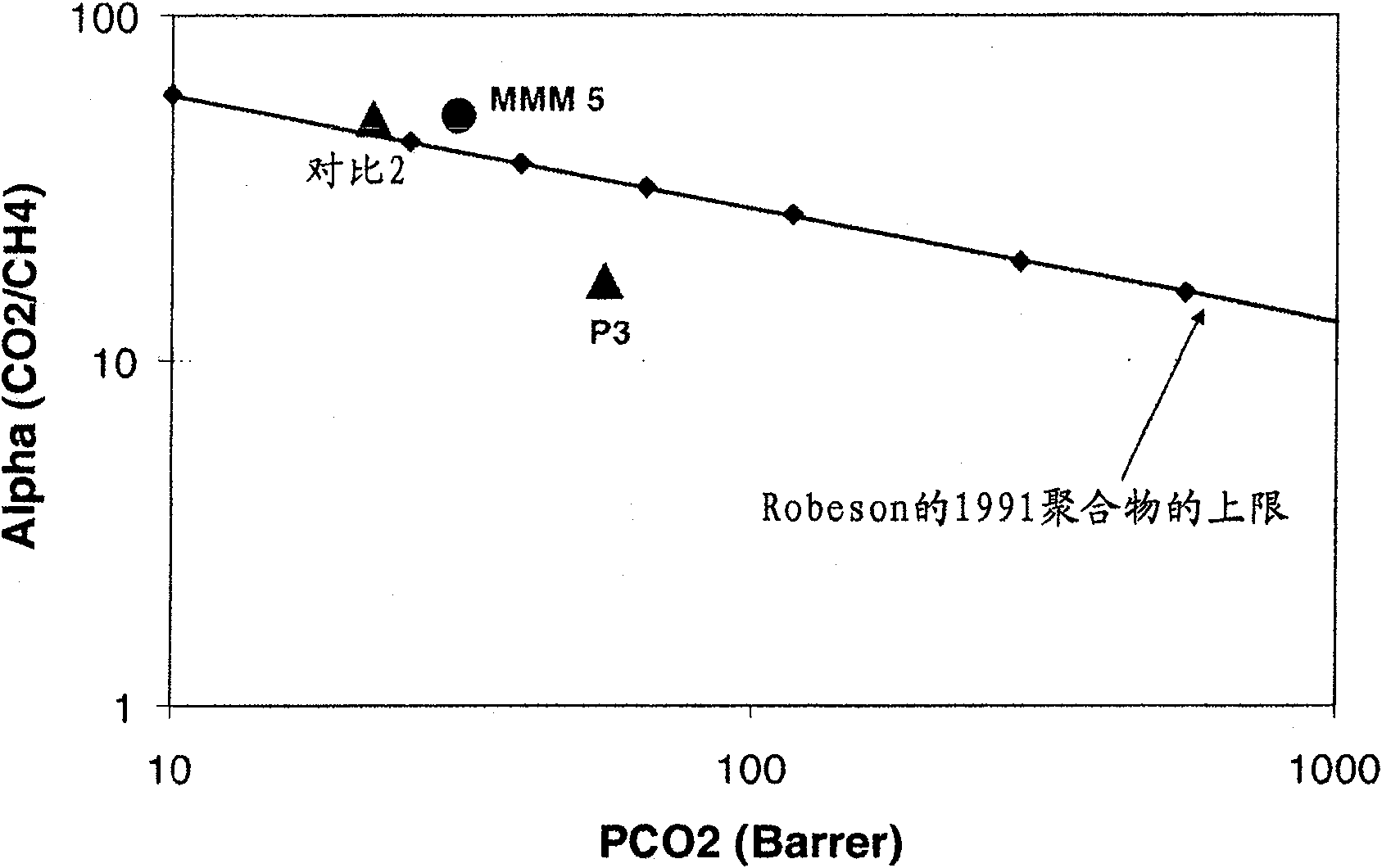

[0078] 5.4g poly(DSDA-PMDA-TMMDA) polyimide polymer ( Figure 9 ) and 0.6g polyethersulfone (PES) are dissolved in a certain amount of an organic solvent or a mixture of several organic solvents (such as NMP, acetone and dioxolane mixed solvent) by mechanical stirring to form a uniform cast film liquid. The resulting homogeneous casting solution was degassed overnight. A poly(DSDA-PMDA-TMMDA) polymer film was prepared from the foam-free casting solution on a clean glass plate with a scalpel at a 20-mil gap. The film was then placed in a vacuum furnace together with the glass plate. Solvent was removed by slowly increasing the vacuum and temperature of the vacuum oven. Finally, the membrane was dried under vacuum at 200°C for at least 48 hours to completely remove residual solvent, forming Tables 1 and 2 and Figure 11 and 12 P1 polymer film as described in . Example 2: Preparation of UV-crosslinked poly(DSDA-PMDA-TMMDA)-PES polymer film (abbreviated as Comparative 1)

Embodiment 2

[0079] Tables 1 and 2 and Figure 11 and 12 The comparative 1 polymer film described in was prepared by exposing the P1 polymer film to UV radiation for further UV cross-linking using UV light with a wavelength of 254nm generated by a UV lamp, the distance between the film surface and the UV lamp 1.9cm (0.75 inches), irradiated at 50°C for 10min. The UV lamps described here were low pressure, mercury arc submerged UV quartz 12 watt lamps, and the 12 watt power supply was supplied by Ace Glass Incorporated. Example 3: Preparation of UV-crosslinked 30% AlPO-14 / PES / poly(DSDA-PMDA-TMMDA) mixed matrix membrane (abbreviated as MMM1)

Embodiment 3

[0079] Tables 1 and 2 and Figure 11 and 12 The comparative 1 polymer film described in was prepared by exposing the P1 polymer film to UV radiation for further UV cross-linking using UV light with a wavelength of 254nm generated by a UV lamp, the distance between the film surface and the UV lamp 1.9cm (0.75 inches), irradiated at 50°C for 10min. The UV lamps described here were low pressure, mercury arc submerged UV quartz 12 watt lamps, and the 12 watt power supply was supplied by Ace Glass Incorporated. Example 3: Preparation of UV-crosslinked 30% AlPO-14 / PES / poly(DSDA-PMDA-TMMDA) mixed matrix membrane (abbreviated as MMM1)

[0080] UV crosslinked polyethersulfone (PES) functionalized AlPO-14 / poly( DSDA-PMDA-TMMDA) mixed matrix membrane (abbreviated as MMM1) was prepared as follows:

[0081] 1.8 g of AlPO-14 molecular sieve was dispersed into the mixture of NMP and dioxolane with mechanical stirring and sonicated for 1 hour to form a slurry. Then 0.6 g of PES was added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com