Method and device for measuring tunnel lining cracks

A measurement method and crack technology, which are applied to measurement devices, optical devices, image data processing, etc., can solve the problems of randomness of shooting distance, cumbersome hand-held contact acquisition process, and inapplicability of edge extraction methods for large cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing.

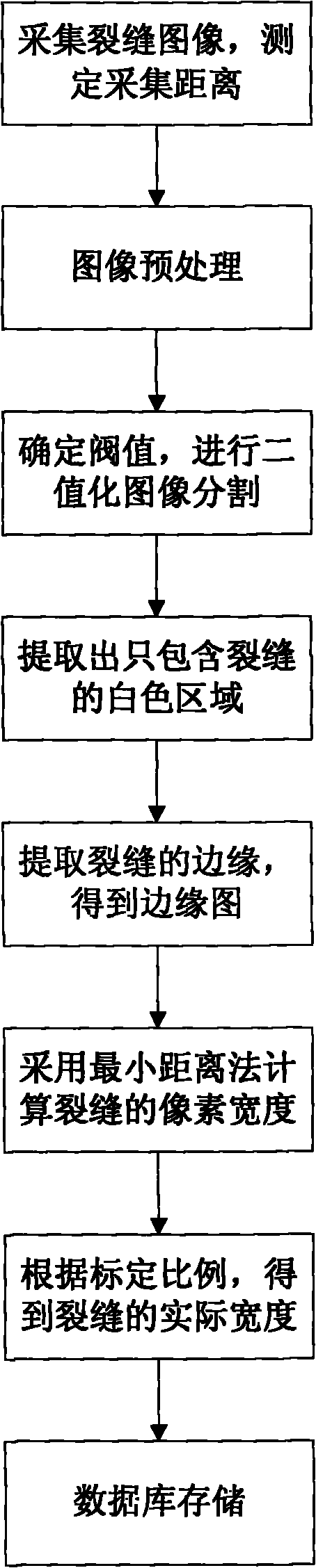

[0065] Such as figure 1 Shown, a tunnel lining crack measurement method, comprising the following steps:

[0066] (1) collect the image of crack by digital camera, and measure the distance collected by laser range finder;

[0067] (2) Select the area to be measured on the collected image to prevent processing deviation due to the large size of the image and the small target crack, and turn the selected area into a grayscale image;

[0068] (3) Determine the threshold value for the gray image selected above, and perform binary image segmentation to obtain the target area; threshold segmentation is the most common direct detection area technology. However, in the entire image, the range of grayscale variation is large and a single threshold value cannot meet the requirements. The present invention dynamically adopts an adaptive threshold value related to the grayscale chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com