Fireproofing vacuum heat-insulating ball valve

A vacuum insulation, ball valve technology, applied in the direction of insulation, valve details, valve device, etc., can solve the problems of user trouble or safety, large torque, short service life, etc., to achieve the effect of convenient operation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

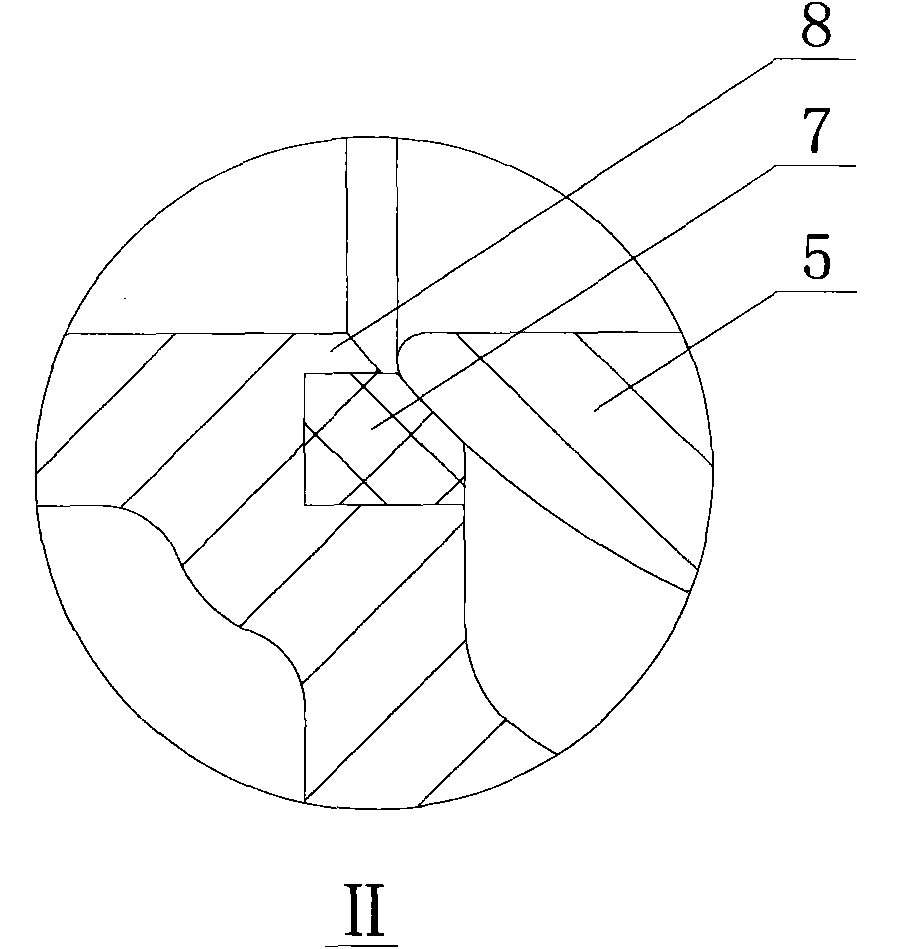

[0011] Referring to the accompanying drawings, the valve body (1) is integrally cast with flanges at both ends for standard pipe connection. There are grooves in the valve body for installing the valve seat sealing ring (8), and the sealing ring is equipped with a fire protection platform. (7), the structure of the fire platform and the valve body; one end of the valve body has an internal thread and the valve seat (3) is connected through the thread, and two grooves are processed on the valve seat for installing the sealing ring (8) and the O-ring (4), the material of the O-ring (4) can be replaced according to the medium used, and the gasket (2) is used for sealing the connection groove between the valve seat and the valve body; the outer layer of the jacket (10) is welded outside the valve body, and the clamp The outer layer of the sleeve and the outer surface of the shell form a cavity space, and two one-way valves (6) are connected to the jacket shell, which are used to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com