Electronically controlled diesel injector driven by electrostriction element

A diesel fuel injector, stretching technology, applied in the direction of engine components, machines/engines, fuel injection devices, etc., to achieve the effect of technical index improvement, scientific structure, high frequency and high pressure diesel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

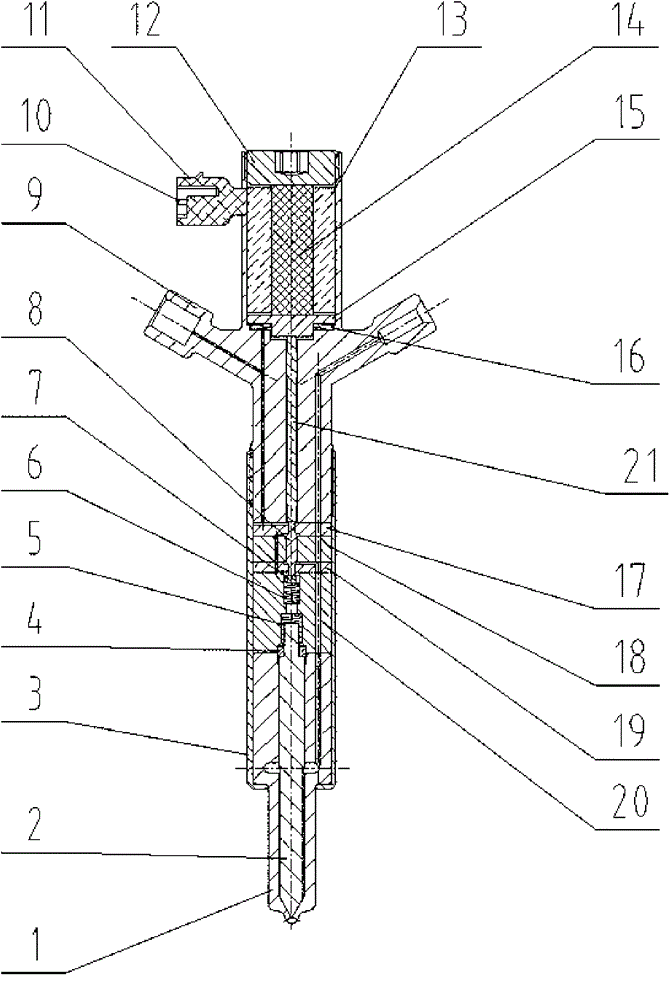

[0028] An electronically controlled diesel fuel injector driven by an electrostrictive element, including a fuel injector housing with an oil inlet passage and an oil return passage, a nut sleeve, and a control nozzle installed in the fuel injector housing and the nut sleeve A mechanism for the axial movement of the needle valve; the mechanism for controlling the axial movement of the needle valve of the fuel injection nozzle is a small axial expansion and contraction produced by the electrostrictive element, and the upper and lower two ends of the needle valve of the fuel injection nozzle are controlled by the command cavity The pressure difference, so as to control the mechanism of axial movement of the injector needle valve;

[0029] A push rod 21, a preload spring 16, a push rod seat 15, an electrostrictive element 14 and a plastic spacer 13 coated on the electrostrictive element 14 are sequentially installed in the injector housing 9 along the axial direction. The electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com