Feeding and pelletizing system for smelting antimony

A technology of feeding and screw feeding machines, which is applied in the field of feeding and granulating systems, can solve the problems of a large backlog of working capital, low ball forming rate of the ball making machine, and high operating intensity of employees, so as to improve economic benefits and size Uniform and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

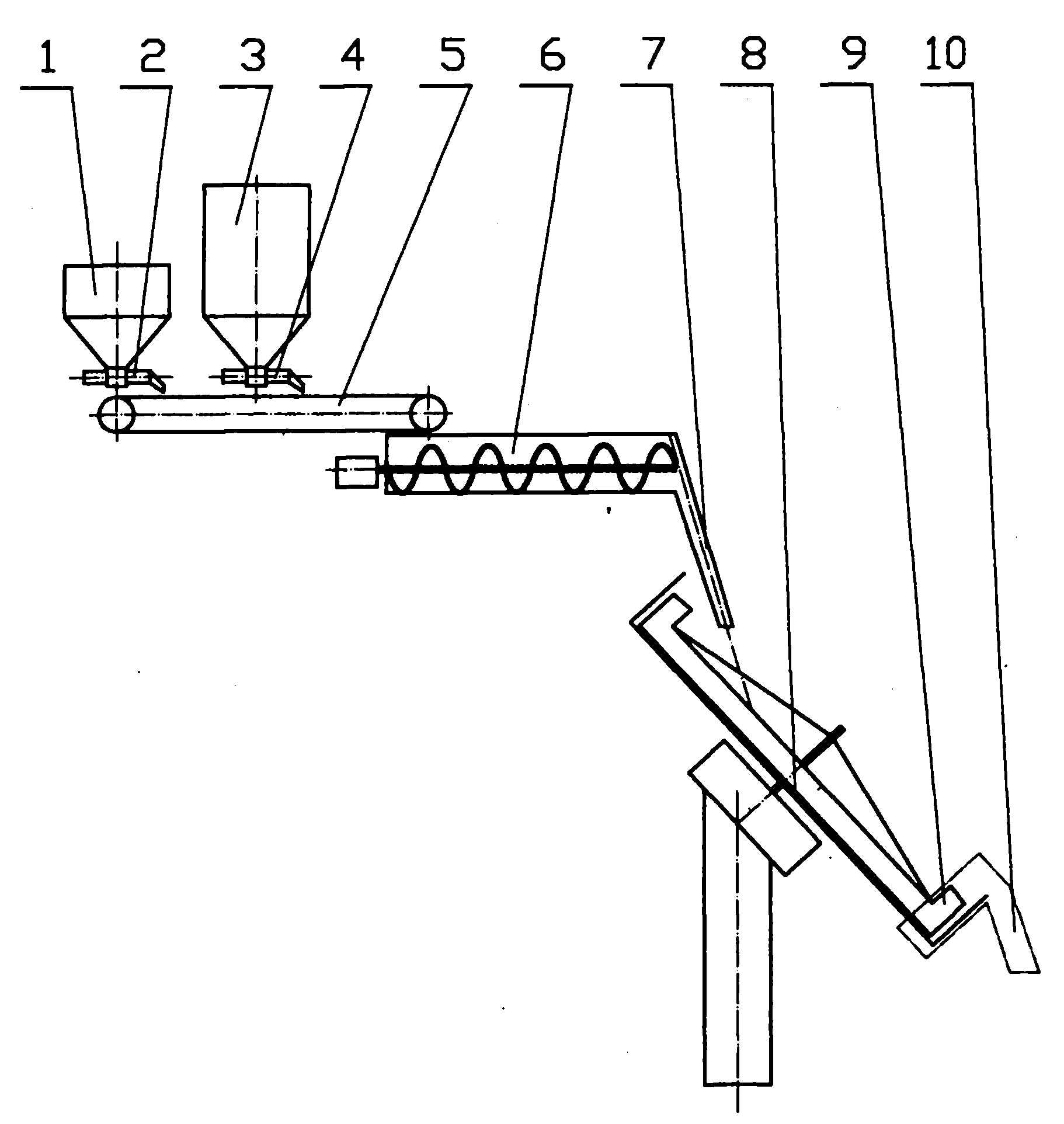

[0009] This embodiment is composed of antimony concentrate hopper 1, antimony concentrate screw feeder 2, refined lime silo 3, refined lime screw feeder 4, batching belt conveyor 5, screw mixing conveyor 6, lower hopper 7, round A pan granulator 8 and a pellet output hopper 10 are formed.

[0010] The antimony concentrate hopper 1 and the fine lime hopper 3 are installed side by side, and the antimony concentrate hopper 1 and the fine lime screw feeder 4 are installed respectively. The batching belt conveyor 5 is installed under the antimony concentrate hopper 1 and the fine lime screw feeder 4, its output end is installed on the upper part of the input end of the screw agitating conveyor 6, and the lower hopper 7 is installed on the output end of the screw agitating conveyor 6 ; The bottom device of the lower hopper 7 is on the top of the disc granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com