Sulphur removal corrosion inhibitor and preparation method thereof

A corrosion inhibitor and formulation technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as economic loss, corrosion damage of drilling equipment, hydrogen sulfide stress cracking of metal materials, etc., and achieve The effect of high balance ability

Active Publication Date: 2012-12-19

SICHUAN ZHENGRONG IND +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

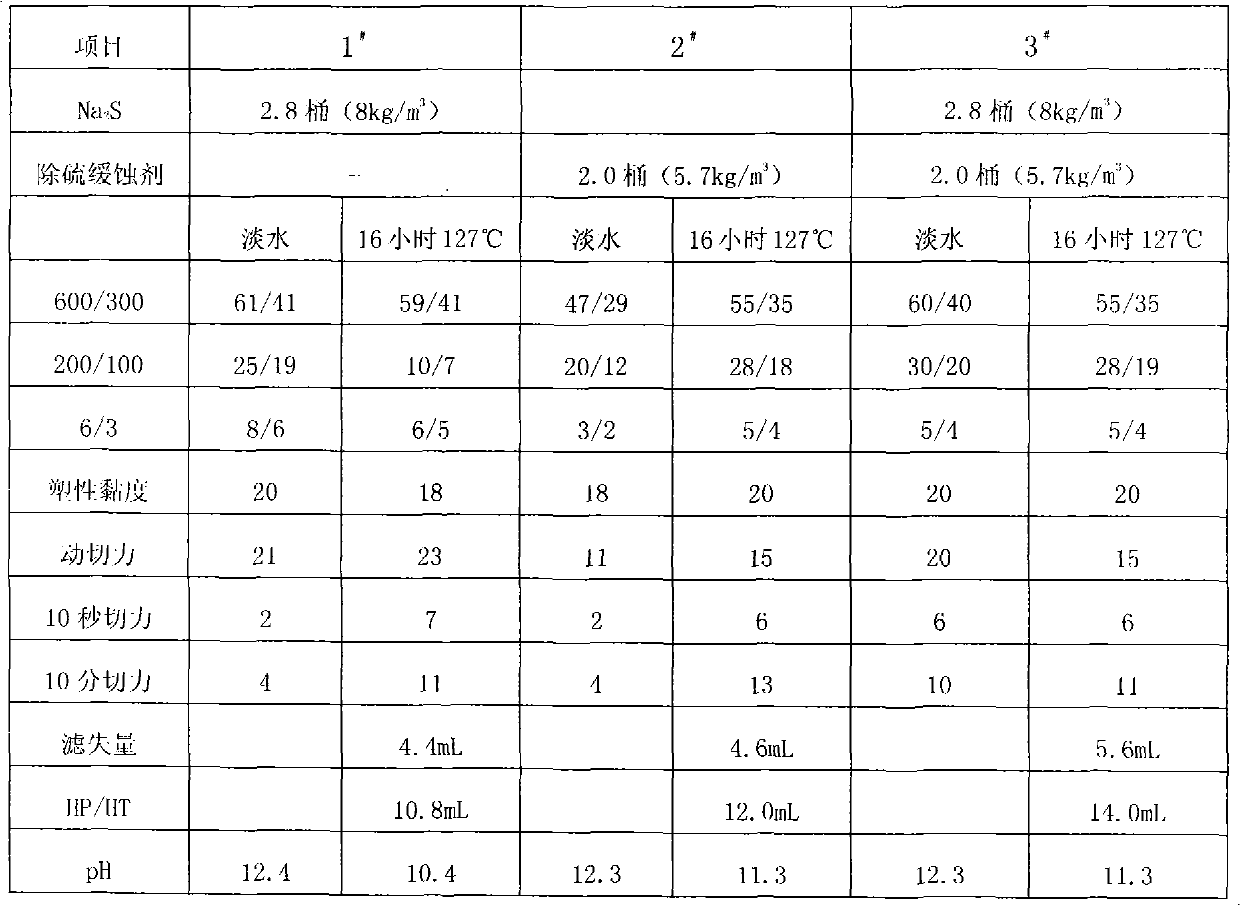

[0105] Add 26% calcium gluconate, 18% ferrous sulfate and 37% water into the meshing machine, heat, stir and mesh, and react at 90°C for 1 hour to obtain the reactant; after drying the obtained reactant Transfer to a pulverizer, add 10% by weight of basic zinc carbonate and 9% of stearamide, fully stir, pulverize for 1 hour, pack and discharge.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

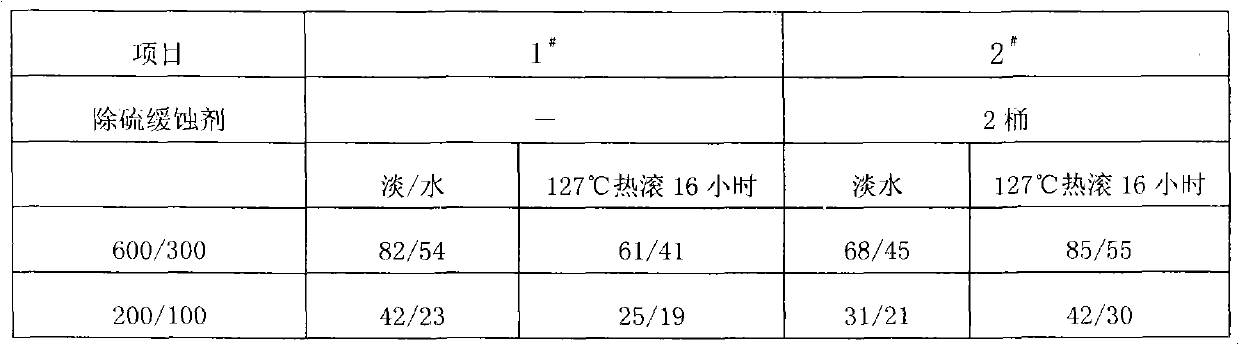

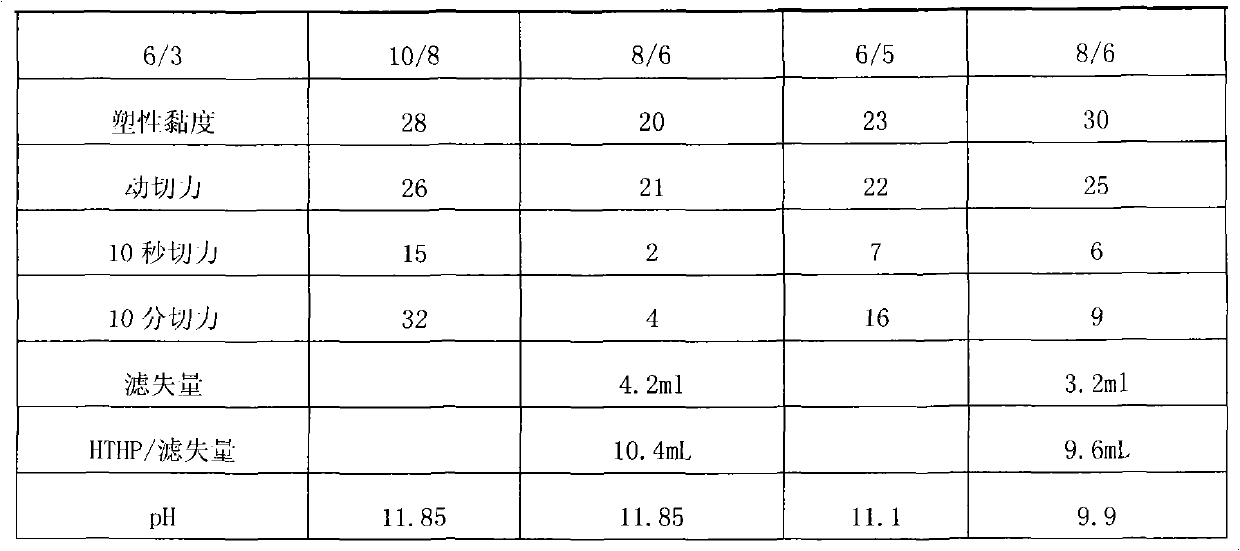

The invention relates to a sulphur removal corrosion inhibitor, which is prepared from the following components in percentage by weight: 26% of calcium gluconate, 18% of ferrous sulfate, 10% of basic zinc carbonate, 9% of stearic amide and the balance of water. The sulphur removal corrosion inhibitor is insensitive to the pH value, has no effect on the rheological behavior of drilling fluid and simultaneously has good compatibility with other finishing agents in the drilling fluid. Ferrous ions in the sulphur removal corrosion inhibitor are easy to absorb by organic matters, a complex compound of the ferrous ions and organic acid is environment-friendly, and the discharge of drilling cuttings and the drilling fluid containing iron ion filtrate cannot cause environmental problems.

Description

technical field [0001] The invention relates to the field of petrochemical industry, in particular to a method for removing the wet H-containing gas contained in the downhole formation during the drilling process. 2 S, CO 2 An iron-based polymer salt desulfurization and corrosion inhibitor added to drilling fluid for harmful gases and a preparation method thereof. Background technique [0002] Sour oil and gas fields refer to the wet H-containing 2 S, CO 2 Oil and gas fields such as harmful gases. During the drilling process in the Sichuan-Chongqing area, when gas layers containing hydrogen sulfide are often encountered, different degrees of H2S often occur. 2 S and CO 2 Air invasion. This is likely to cause corrosion damage to drilling equipment by contaminated drilling fluid, especially H 2 S will not only lead to sudden hydrogen sulfide stress cracking of metal materials, causing huge economic losses, but also H 2 The toxicity of S will threaten personal safety. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/54C09K8/06

Inventor 王刚毅何纶

Owner SICHUAN ZHENGRONG IND

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com