Petroleum sulfonate composition, preparation method and application thereof

A petroleum sulfonate and composition technology, which is applied in the direction of sulfonate preparation, sulfonic acid preparation, drilling composition, etc., can solve the problem that the quantity of synthetic products cannot meet the composite flooding field test, cannot achieve ultra-low interfacial tension, Reduce the oil-water interfacial tension, wide molecular weight range, and reduce the cost of synthetic products to solve problems such as shortened pump inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

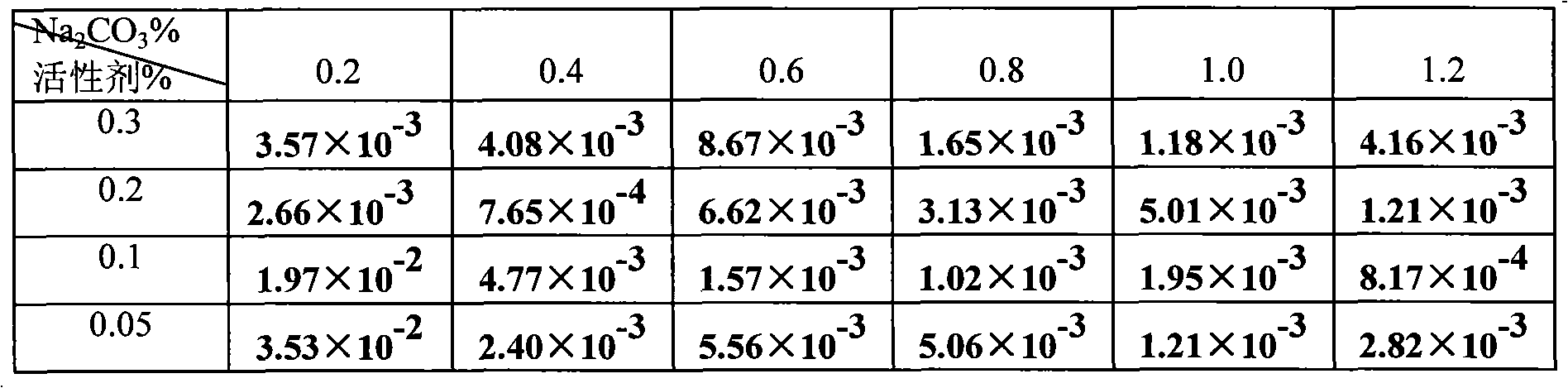

[0031] The present invention adopts the reverse-sequence dewaxed oil of the second line of decompression and the third line of decompression of Dalian Petrochemical Plant as raw materials, and the ratio is 60:40 (W / W), SO 3 The sulfonation reaction temperature is 60°C, neutralized with 25% NaOH solution, so that the pH value of the product reaches 7-10, and the obtained homogeneous product is sodium petroleum sulfonate surfactant (active substance effective content 35%). Table 1 shows the interfacial tension test results of the synthetic product on the oil and water of Daqing No. 4 Plant. The interfacial tension testing instrument adopts TEXAS-500C spinning drop interfacial tensiometer, and the surfactant is formulated with formation water reinjection sewage from oil field oil production plant to a concentration of 0.05-0.3% (wt), and the interfacial tension is a stable equilibrium value for 2 hours of testing. It can be seen from the experimental data that, in addition to the...

Embodiment 2

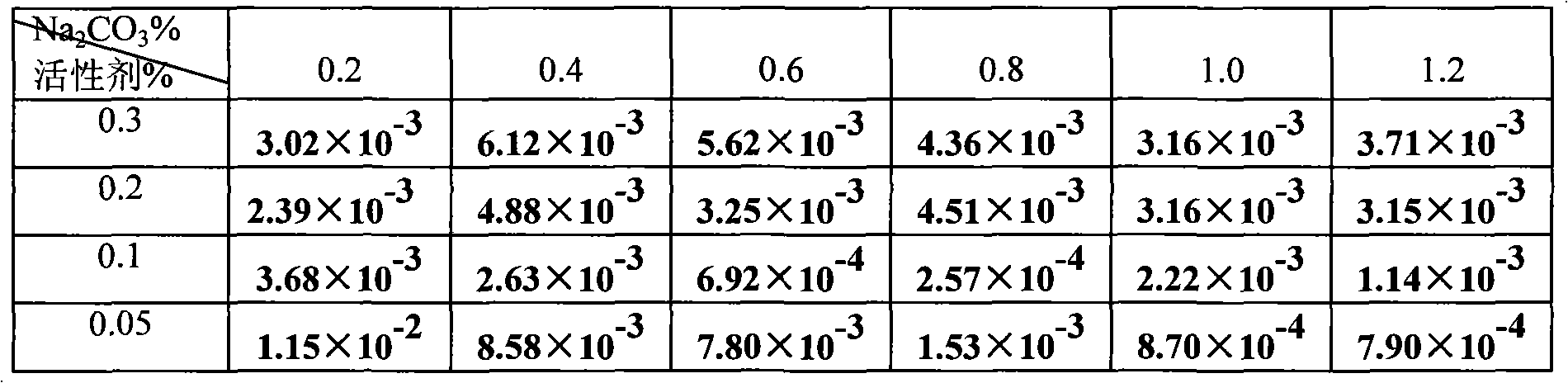

[0036] The present invention uses Dalian Petrochemical Plant's decompression second line, decompression third line reverse sequence dewaxed oil and decompression second line furfural extracted oil as raw materials, the ratio is 55:30:15 (W / W / W), SO 3 The sulfonation reaction temperature is 65°C, neutralized with 20% NaOH solution, so that the pH value of the product reaches 7-10, and the obtained homogeneous product is sodium petroleum sulfonate surfactant (active substance effective content 40%). Table 2 shows the interfacial tension test results of the synthetic product on the oil and water of Daqing No. 4 Plant. The surface active agent is prepared with formation water reinjection sewage from an oil field oil production plant to a concentration of 0.05-0.3% (wt), and the interfacial tension is a stable equilibrium value after testing for 2 hours.

[0037] Table 2 Petroleum sulfonate product PS-2 to crude oil / sewage interfacial tension of Daqing No. 4 Plant

[0038] (polyme...

Embodiment 3

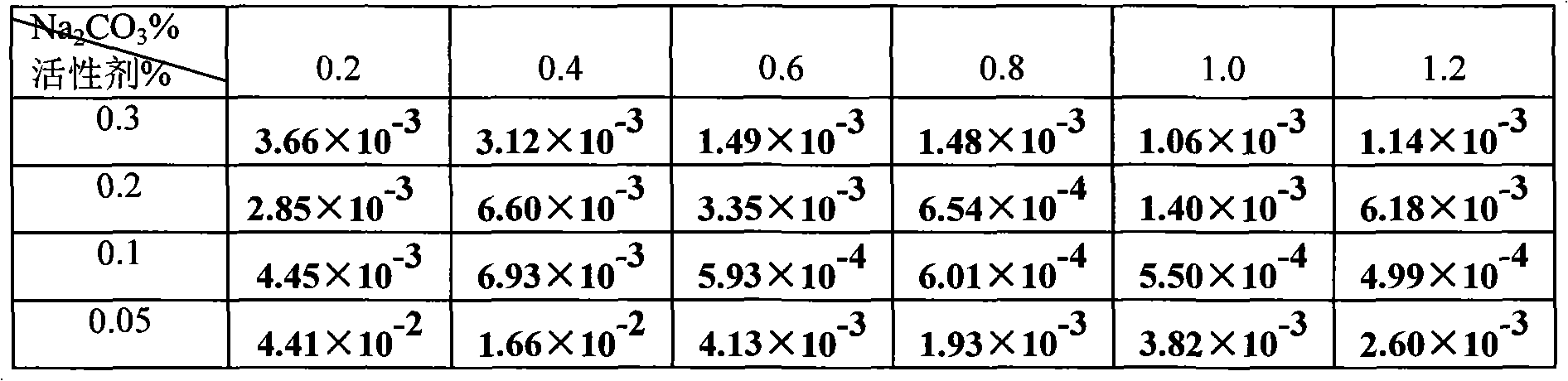

[0041] The present invention uses Dalian Petrochemical Plant decompression second line, decompression third line reverse sequence dewaxed oil and decompression second line furfural extracted oil as raw materials, the ratio is 55:25:20 (W / W / W), SO 3The sulfonation reaction temperature is 65°C, neutralized with 20% NaOH solution, so that the pH value of the product reaches 7-10, and the obtained homogeneous product is sodium petroleum sulfonate surfactant (active substance effective content 44%). Table 3 shows the interfacial tension test results of the synthetic product on the oil and water of Daqing No. 4 Plant. The surface active agent is prepared with formation water reinjection sewage from an oil field oil production plant to a concentration of 0.05-0.3% (wt), and the interfacial tension is a stable equilibrium value after testing for 2 hours.

[0042] Table 3 Petroleum sulfonate product PS-3 to crude oil / sewage interfacial tension of Daqing No. 4 Plant

[0043] (polymer H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com