Advanced treatment method of industrial waste water by combining catalysis internal electrolysis, coupling, oxidization and flocculation

A technology for advanced treatment of industrial wastewater, applied in oxidation water/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficulty in meeting discharge standards, inability to continue to use biological treatment, and the danger of pollutants, etc. problems, to achieve the effect of reducing the cost of chemicals, excellent decolorization effect, and high removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

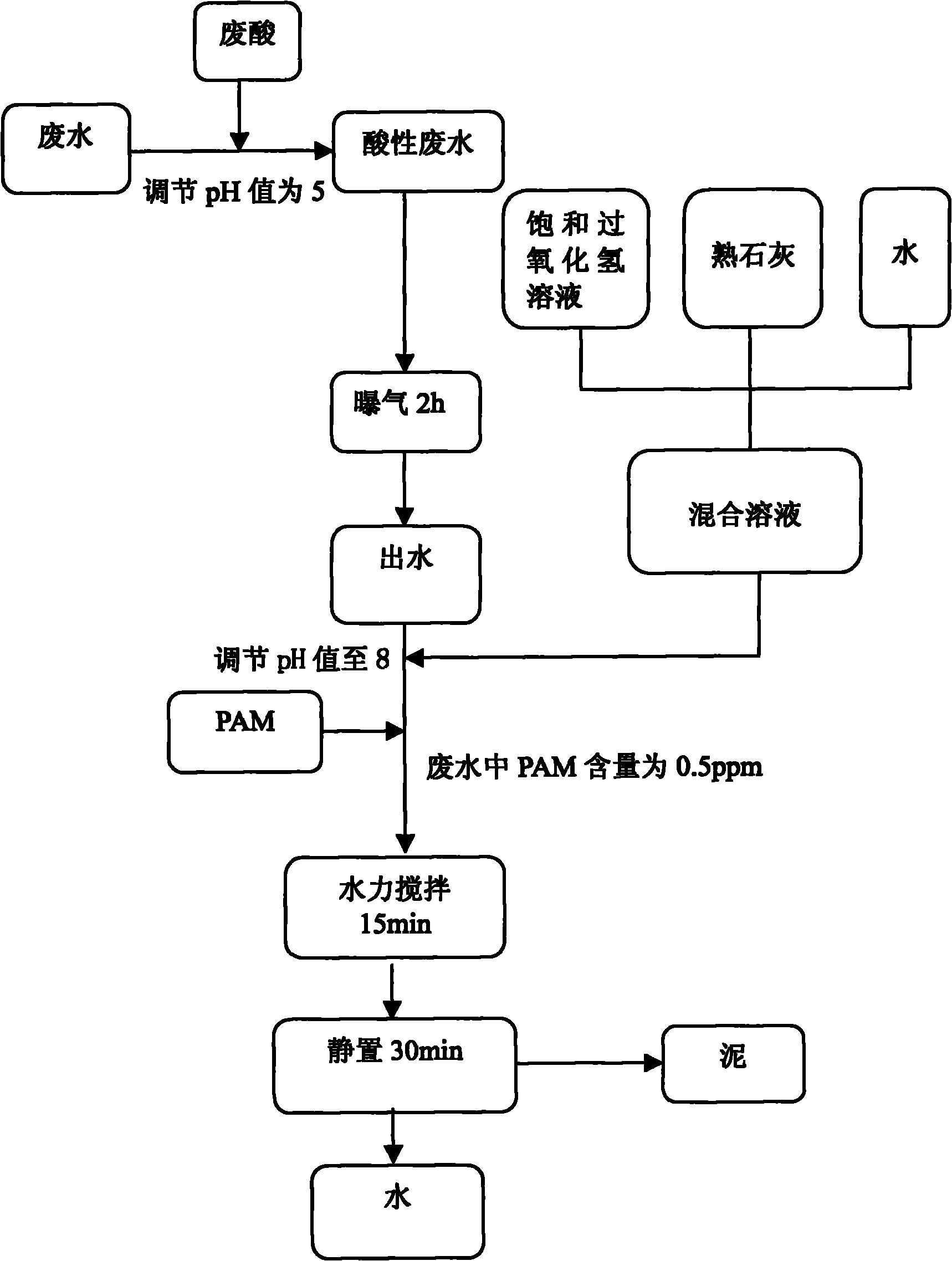

[0026] Please see the process figure 1 .

[0027] 1. To biochemical effluent (COD) from a paper mill Cr 290mg / L, chroma about 220 times), add a certain amount of waste acid solution into the wastewater, stir, and adjust the pH value of the wastewater to about 5.

[0028] 2. Add the self-made Pall ring packing into the wastewater in the same shape as the national standard Pall ring packing. The Pall ring packing is composed of Pall ring packing with an iron-carbon volume ratio of 1:1. Add filler according to the ratio of 10 fillers / L wastewater, and aerate for 2 hours to produce water;

[0029] 3. According to the configuration of slaked lime: hydrogen peroxide solution (mass fraction is 30%): water = 2:1:17 (mass ratio), after stirring evenly, a mixed solution is obtained, and the mixed solution is added to the internal electrolytic aeration. For the wastewater effluent, the dosage of the mixed solution shall be subject to the pH value of the effluent reaching 8-9;

[0030...

Embodiment 3

[0037] The operation process of Example 1 was applied to treat the biochemical effluent of industrial sewage, and the experimental water was taken from the biochemical effluent of a certain printing and dyeing factory. Compare the catalytic internal electrolysis coupling oxidation flocculation method of the present invention with the addition of conventional flocculants, see Figure 4 shown.

[0038] The water quality of the biochemical effluent in the printing and dyeing plant is: COD Cr It is 220mg / L, and the chromaticity is 300 times. Catalyzed internal electrolysis coupling oxidation flocculation is used for advanced treatment, while the treatment efficiency of conventional chemicals (PAC and aluminum sulfate) is compared at the same time. The coagulation test was carried out under the condition of the optimal dosage of conventional chemicals, and 0.5mg / L polyacrylamide coagulant was added. The results are compared as follows:

[0039] COD of printing and dyeing wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com