Vertical servo hydraulic tool rest

A hydraulic and vertical technology, applied in the field of mechanical processing, can solve the problems such as the inability to effectively guarantee the braking force, the gear teeth and the gear shaft are easily broken, and the transmission torque is small, so as to improve various performances, reduce the strength of the gears, and improve the transmission efficiency. Low torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

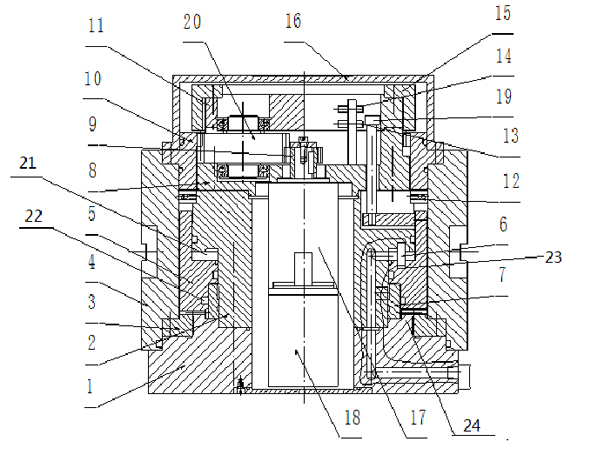

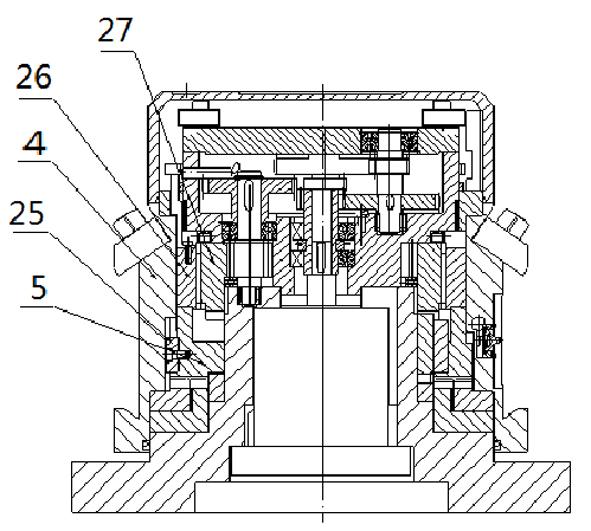

[0032] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

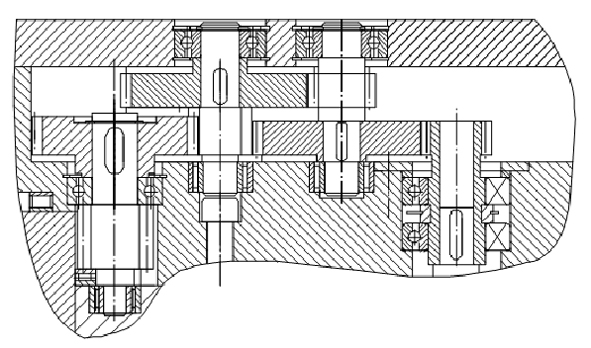

[0033] Depend on figure 1 As shown, the hydraulic support includes a base 1, a hollow vertical shaft 2, a transmission system, a bearing seat 8, an inner ring gear 10, a tool table 4, and a brake release assembly. The middle part of the base 1 is vertically fixed with a hollow vertical shaft 2, and the hollow vertical shaft The upper end of 2 is fixed with bearing seat 8, and transmission system wherein is fixed on the bearing seat 8. The transmission system mainly includes a servo motor 18, the output end of which is connected to a reducer 17. The reducer 17 is a high-precision planetary reducer. The reducer 17 and the servo motor 18 are fixed on the lower end surface of the bearing seat 8. Through the bearing seat 8, the driving gear 9 is fixed on it, and the transmission gear 20 which is externally meshed with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com